'MAF Roda Agrobotic's dedicated cherry system controls post-harvest from cherry's harvest to the punnets, ready to be delivered to the customer. It is designed for maximum efficiency and works as if it were a single machine'.

'In this regard, the latest novelty concerning the plant is the inclusion of a weighing and packaging machine for 250 gram and 500 gram and one-kg punnets,' Marco Masotti is Sales Manager for MAF Roda Agrobotic Italia and told Cherry Times about the advantages of relying on the French company for everything related to post-harvest management.

MAF Roda recently celebrated 60 years in business and is one of the world's leading companies in automatic and customised solutions for grading, sorting and packaging of fruit and vegetables. It is still a family business, with 1200 employees and an international dimension.

It has offices in practically every part of the planet: from China to Australia, from Mexico to South Africa to the United States to New Zealand. Headquartered in Montauban, France, the robotics department is constantly designing new machines incorporating the latest technological advances.

Cherries, a challenging fruit in post-production

'We started dealing with cherries during the early 2000s,' Marco Masotti told us, 'the cherry is a very challenging fruit. It is highly subject to seasonality, it is very variable both within the season and within the territory. It therefore has extreme variance, there will never be one year that is the same as another even within the same territory. Types and severity of defects differ greatly'.

'Moreover, cherries are sold with the stalk, which increases its value on the market and this complicates the vision a lot'.

'Adding to the complexity is the fact that the season is very short and the volumes to be processed are very high, often with unskilled labour because they are only hired for the cherry processing period. However, the correct selection of the fruit is fundamental to minimise waste and correctly differentiate the first quality from the second. Much of the margin, in fact, is made by optimising the grading'.

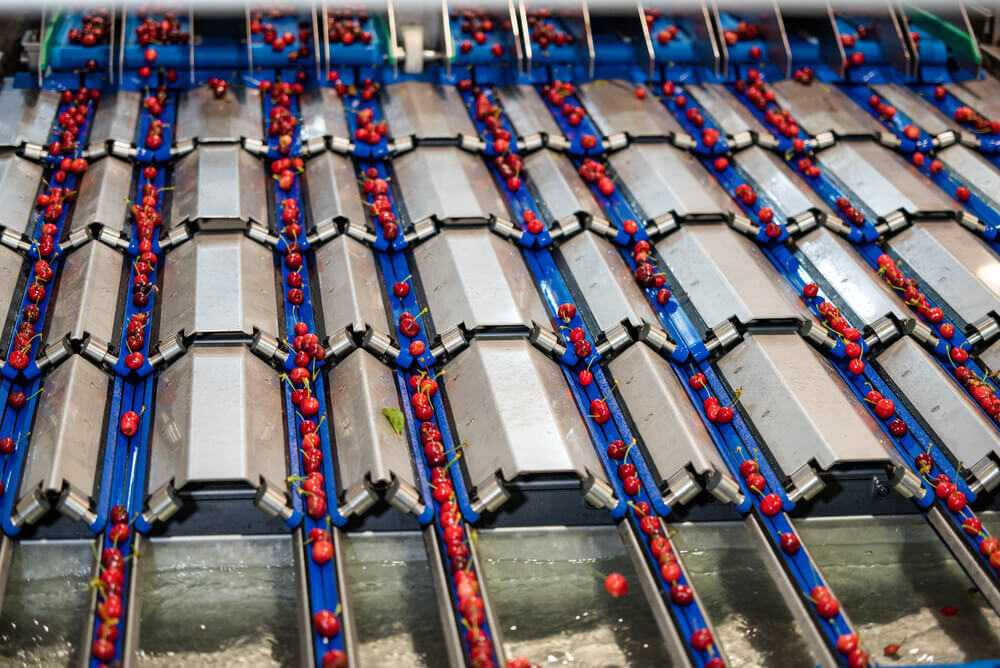

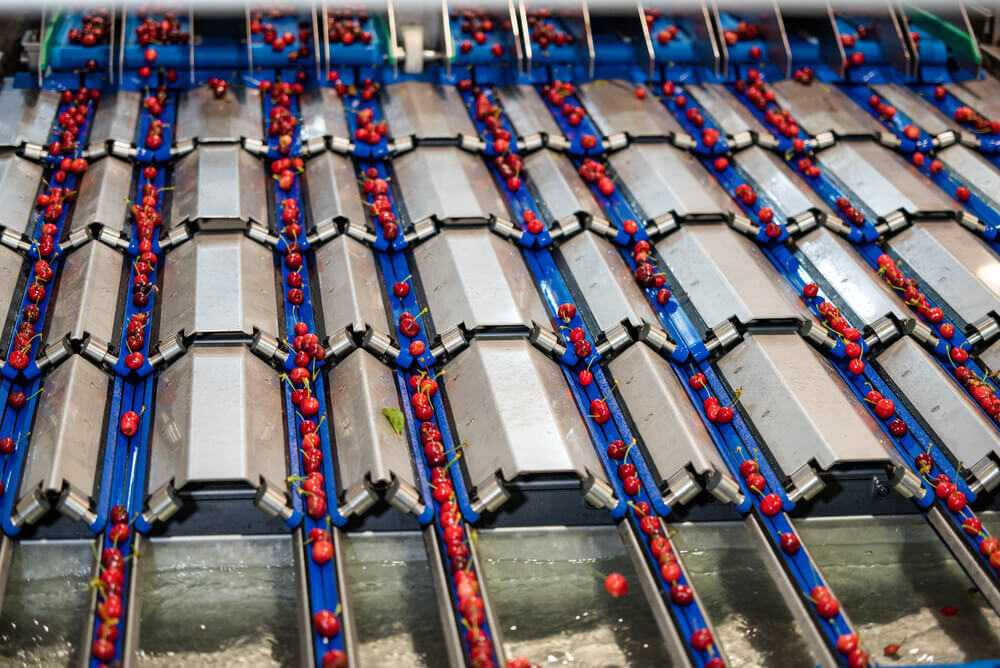

Cherry Way IV analyses cherries at 360 degrees

The flagship of the post-harvest cherry processing system is the Cherry Way IV grader, which has been collecting awards since its launch in 2021. The latest accolade was 'product of the year' at the 2022 Suplemento National Awards.

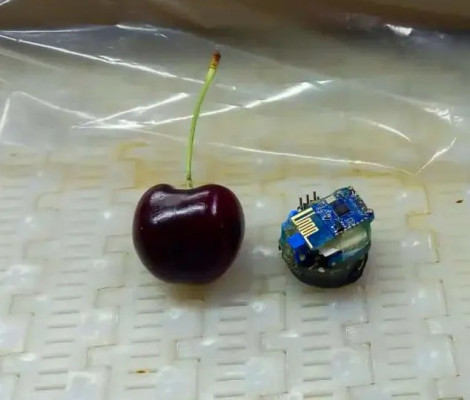

'It is a complex machine," Masotti told us, "consisting of several stages. It boasts the system that rotates each individual cherry so that the stalk does not disturb the analysis of the fruit and its selection. Each individual fruit is put into rotation and the machine rotates 30 fruits per second per line, up to a maximum of 10 lines'.

The rotation system is based on 4 automatic movements and allows the entire surface of the cherry to be scanned.

The fruit is graded according to colour, size and according to the defects found: 'The Cherry Way IV grader is integrated with the Cherryscan 7 vision system using artificial intelligence. The multi-spectral infrared camera that analyses the fruit does so by taking colour photos at 5 different wavelengths'.

'Some fruits are in fact only discriminable with infrared. The technology is able to classify the type of defect, hail damage from an insect bite, for example. To this global view of the fruit we have added a very intuitive software for the operator'.

'Even an operator new to the job is guided by artificial intelligence in his work. We have had proof that the quality of the result does not change if the system is operated by an experienced operator rather than a novice'.

On the other hand, the possibility of recruiting skilled workers on the market only for the narrow period of the fruit harvest is increasingly rare. The shortage of manpower in the fruit and vegetable sector, especially if it is specialised, is well established. Artificial intelligence is an aid to the operator who can thus anticipate the result of his selection by setting the parameters correctly.

With the weighing machine, automatic packing of punnets

'Having a correct classification of cherries and eliminating, in the selection phase, those that are problematic makes it possible to lengthen the shelf life of the product, which can then eventually reach more distant markets. At the end of the circuit, the fruit is pneumatically released at the exit identified by the classification'.

At this point, the cherries are ready for packaging, which can be manual or automatic. 'Our weighing machine,' concluded Marco Masotti, Sales Manager for MAF Roda Agrobotic Italia, 'automatically packs punnets and is perfectly integrated into the cherry planting system. Also in this case we have tried to meet the demand for less manpower, as it is becoming increasingly difficult to find it'.

A questo punto le ciliegie sono pronte per il confezionamento che può essere manuale o automatico: “La nostra macchina pesatrice – ha concluso Marco Masotti è Sales Manager per MAF Roda Agrobotic Italia – confeziona i cestini in maniera automatica ed è perfettamente integrata nell’impianto dedicato alla ciliegia. Anche in questo caso abbiamo cercato di dare soddisfazione alla richiesta di impiegare meno manodopera, è infatti sempre più difficile reperirla”.

Barbara Righini

Images: MAF Roda

Cherry Times - All rights reserved