Cherries are highly appreciated by consumers, but being a highly perishable product, their commercial life is short and can be influenced by various factors. For this reason, once harvested, the fruits must be quickly brought to a place where they undergo a proper post-harvest process that allows maintaining quality and maximizing the commercial life of the product.

In this sense, the correct management of temperature is a key factor in ensuring quality cherries. Low temperatures (around 0ºC) and high humidity (90-95%) allow maintaining good quality for at least 2 weeks. However, with temperatures between 4º-6ºC, this storage period is reduced to 4-8 days.

For this reason, it is essential to perform a rapid cooling of the harvested fruits to lower the field temperature as soon as possible. The most used method for this purpose in cherries is the hydrocooler, which allows rapid cooling while preventing the fruit from losing water. Similarly, all subsequent handling must be done at cold temperatures, below 6º-4ºC.

As with cooling, much of the post-harvest processing of cherries takes place in water, with tipping, transportation along the line, and post-harvest treatment. This minimizes bruising damage and ensures that the fruit is kept at the right temperature throughout the process.

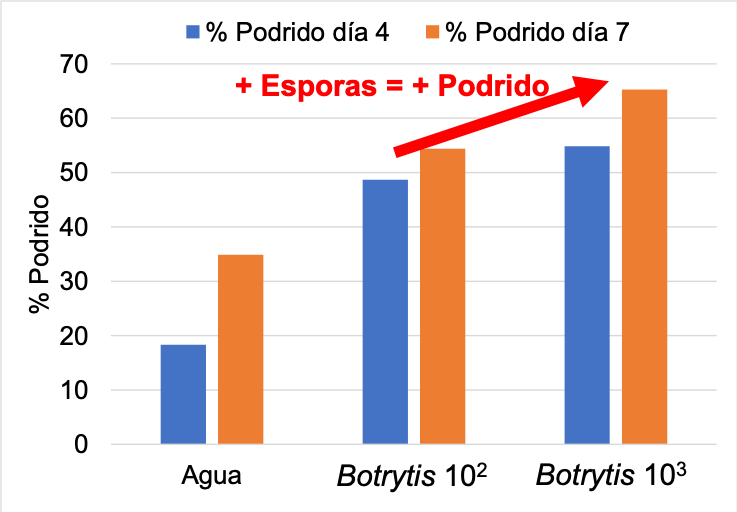

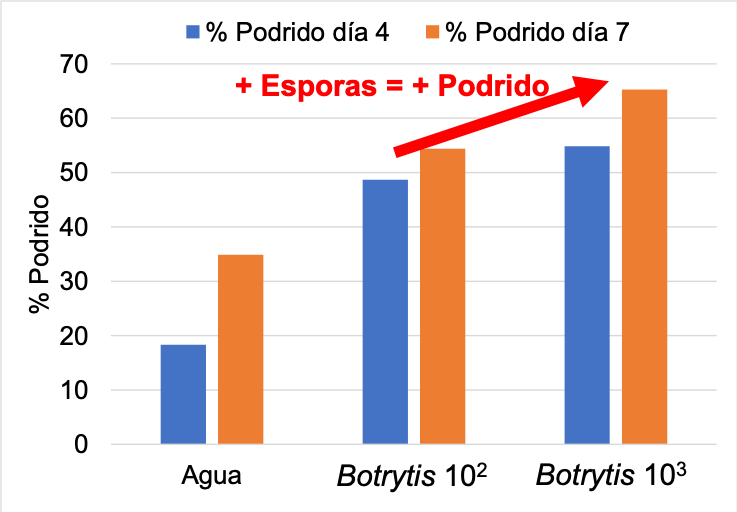

On the other hand, the correct application of a post-harvest fungicidal treatment is essential to control decay and thus reduce complaints upon fruit arrival. The most frequent pathogens are Monilinia, Botrytis, Alternaria, or Penicillium. Proper management of water hygiene during the entire post-harvest process of cherries is also vital, as water can act as a vector, even increasing the levels of deterioration of the fruits (Figure 1).

Image 1: Figure 1: % deterioration in cherries washed with tap water or water contaminated with Botrytis spores at different concentrations (Botrytis 102 = 100 spores/ml; Botrytis 103 = 1000 spores/ml) after 4 and 7 days at 22°C.

Image 1: Figure 1: % deterioration in cherries washed with tap water or water contaminated with Botrytis spores at different concentrations (Botrytis 102 = 100 spores/ml; Botrytis 103 = 1000 spores/ml) after 4 and 7 days at 22°C.

For over 10 years, based on "in situ" research studies at various cherry processing plants in Spain, Chile, and Turkey, Citrosol has developed innovative solutions to maintain the quality and shelf life of cherries. These solutions reduce the industrial variability we have observed in the post-harvest processes studied.

Citrocide® PLUS and PC: highly effective peracetic formulations for controlling all types of microorganisms. They leave no residue on the fruit and are certified as inputs for organic farming in accordance with European regulations. Citrocide® does not generate disinfection by-products (DBP) that are potentially harmful to people or the environment.

Citrocide® systems: includes a range of solutions for the monitoring and control of Citrocide® in refrigerated water and in cherry processing.

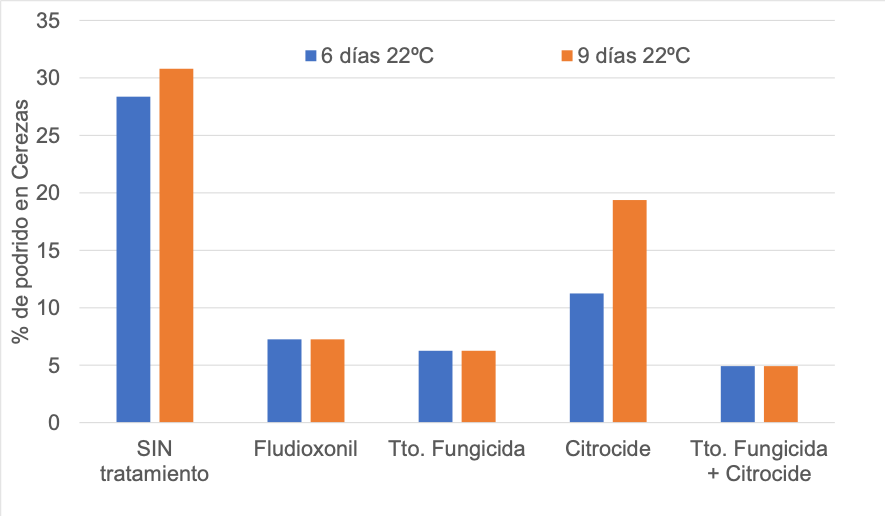

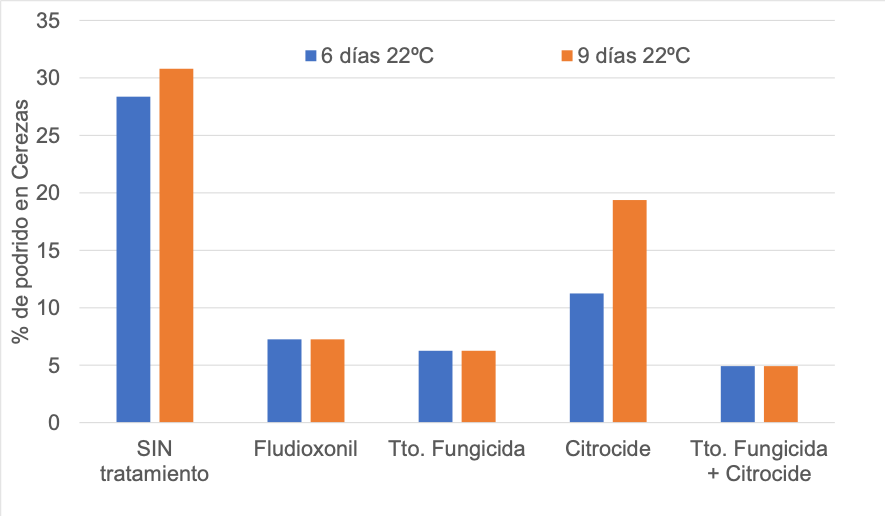

The systems allow the fully automatic dosing of Citrocide® into the hydrocooler water, the drainage basin, the peeler, or the conveyor and to monitor the product's concentration in the water, thus maintaining the optimal dosage and the process water in hygienic conditions. This ensures the food safety of the product and significantly improves the results of decay control (Figure 2).

Image 2: Figure 2: % deterioration in cherries inoculated with Monilinia spp + Botrytis spp, and after being washed with cold water (WITHOUT treatment), treated with a post-harvest fungicide, washed with Citrocide® or with a combination of both.

Image 2: Figure 2: % deterioration in cherries inoculated with Monilinia spp + Botrytis spp, and after being washed with cold water (WITHOUT treatment), treated with a post-harvest fungicide, washed with Citrocide® or with a combination of both.

The Citrocide System is also compatible with the Vertido Cero® filter, which eliminates the suspended solids that both the fruits and the field containers bring to the hydrocooler water, dirtying it and causing its replacement. Thanks to the combined action of both units, the use of hydrocooler water can be extended, reducing water consumption and cooling, and improving the sustainability of the cherry post-harvest process.

Citrosol DS: system for dosing and controlling the fungicidal treatment in the cherry processing line. The dosing equipment keeps the initial fungicidal effectiveness constant and unaltered, allowing for a more extended use.

CitroFy: a platform that integrates and unifies in a single product the monitoring and control of all Citrosol application systems. The technologies developed by Citrosol to reduce industrial variability in cherry post-harvest processes allow processing plants that use them to control decay with higher levels of industrial reliability.

Source: Valencia fruits

Images: Valencia fruits

Cherry Times - All rights reserved