Major crops, viticulture and, at least to some extent, fruit growing and industrial horticulture, have largely benefited from the technological innovations introduced into production processes through mechanisation. In contrast, the fruit sector for the fresh market still remains highly dependent on manual labour, particularly for pruning and harvesting operations.

"Cherry growers need tried and tested, research-validated, efficient and cost-effective technical solutions in order to increase plant efficiency, maintain high product quality according to market demands and, above all, reduce production costs. These include the possibility of mechanising some cultivation operations, such as pruning and harvesting'. Prof. Matthew Whiting of WSU announced it at the opening of the keynote lecture he gave at last year's ICS at Macfrut (Whiting, 2022): "the future lies here".

The declining availability of skilled labour and the rising costs of raw materials and labour are seriously jeopardising the economic sustainability of the entire supply chain. It is precisely on the economic balance sheet of the enterprise that the future of specialised cherry farming is at stake.

Counting in hand, producing cherries in modern, covered facilities costs on average between EUR 3.20 and EUR 3.55/kg, depending on the type adopted. 60-70% of production costs are attributable to harvesting and pruning (Ghelfi and Palmieri, 2022).

Development of planar breeding systems

At Washington State University and Oregon State University, a multidisciplinary team of agronomists and engineers has studied various methods to improve production efficiency, with a focus on pruning and harvesting.

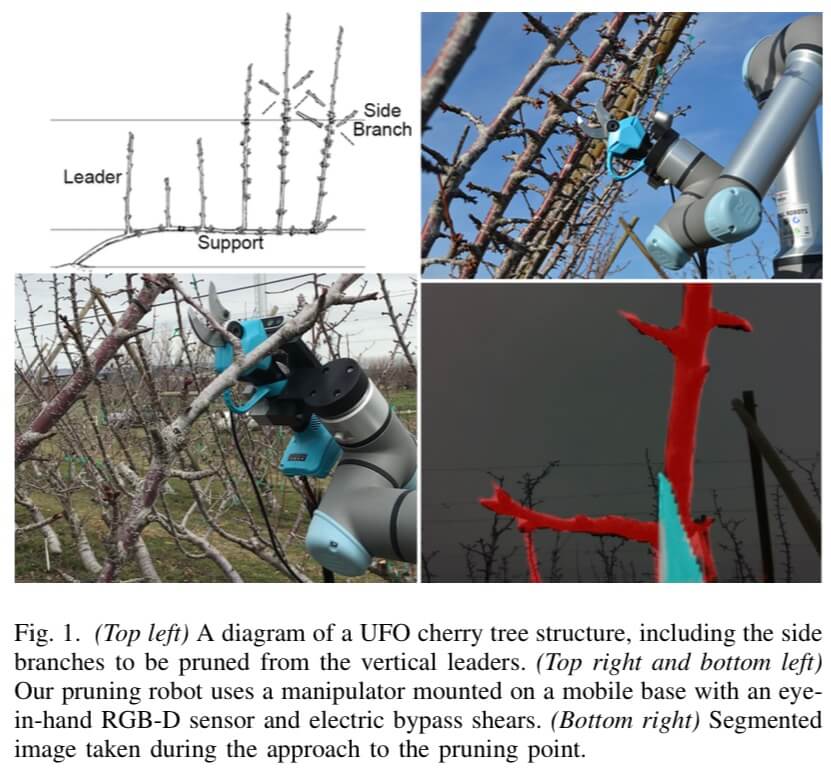

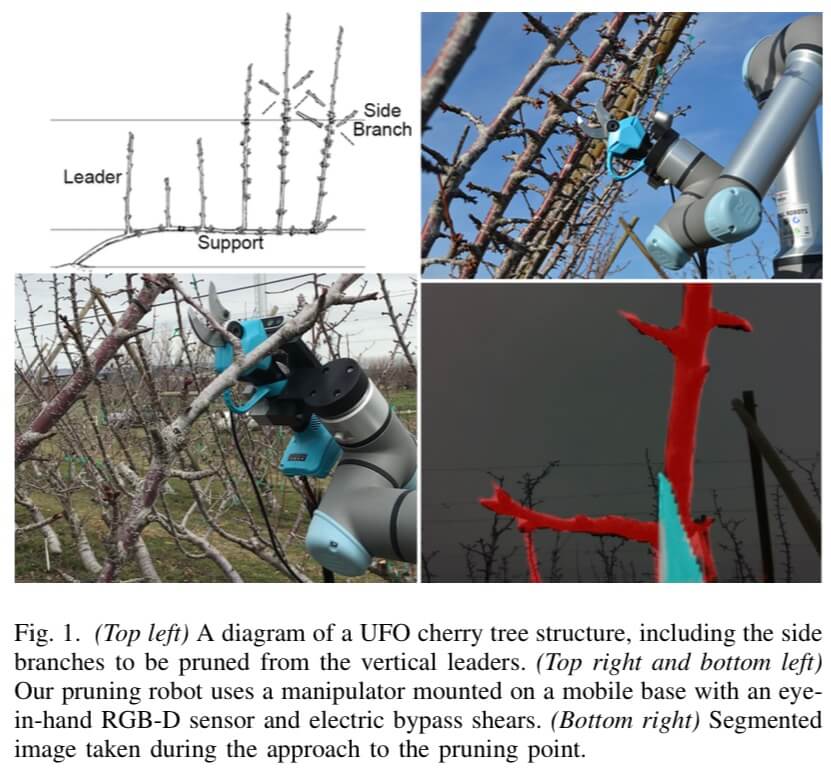

The long-term goal is to improve production efficiency and profitability while maintaining or improving fruit quality. "In order to achieve this goal," Whithing continues, "our group has perfected cherry tree breeding forms with two-dimensional, compact fruit parcels based on the UFO - Upright Fruiting Offshoots - model. Furthermore, engineering solutions for pruning, pollination, and mechanical thinning have been developed and studied, as well as both fully mechanical and mechanically assisted harvesting systems.

It is clear that the forms of cultivation will have to adapt to current and future automation and mechanisation technologies, and similarly, research into such technologies cannot take place without consulting the opinion of those working in the sector, both from an operational and a re-search perspective.

The gradual evolution of training forms, from large three-dimensional structures to planar structures strictly and geometrically trained in narrow walls with renewable vertical cords, together with the adoption of precision techniques in canopy management, therefore offer the opportunity to adopt mechanisation and consequently reduce pruning costs.

One of the initial key objectives that American researchers had set themselves in the development of new 2D forms of plant breeding was precisely to simplify the interventions required for production pruning as much as possible.

Selective mechanical pruning

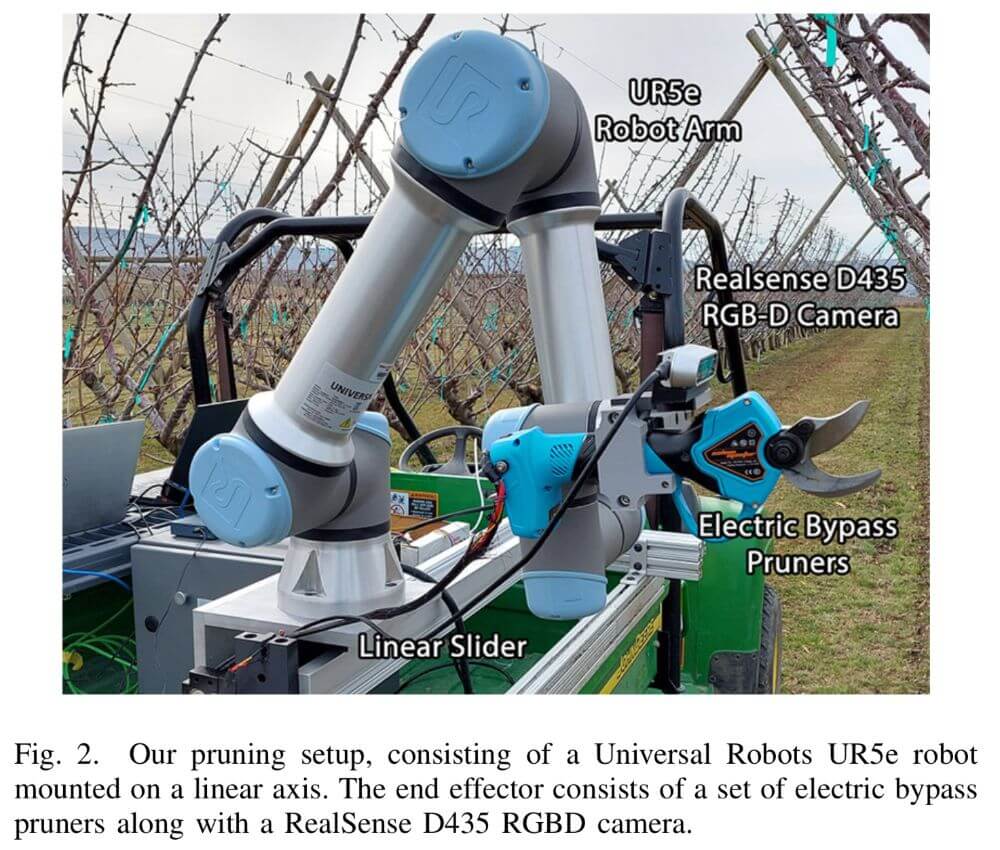

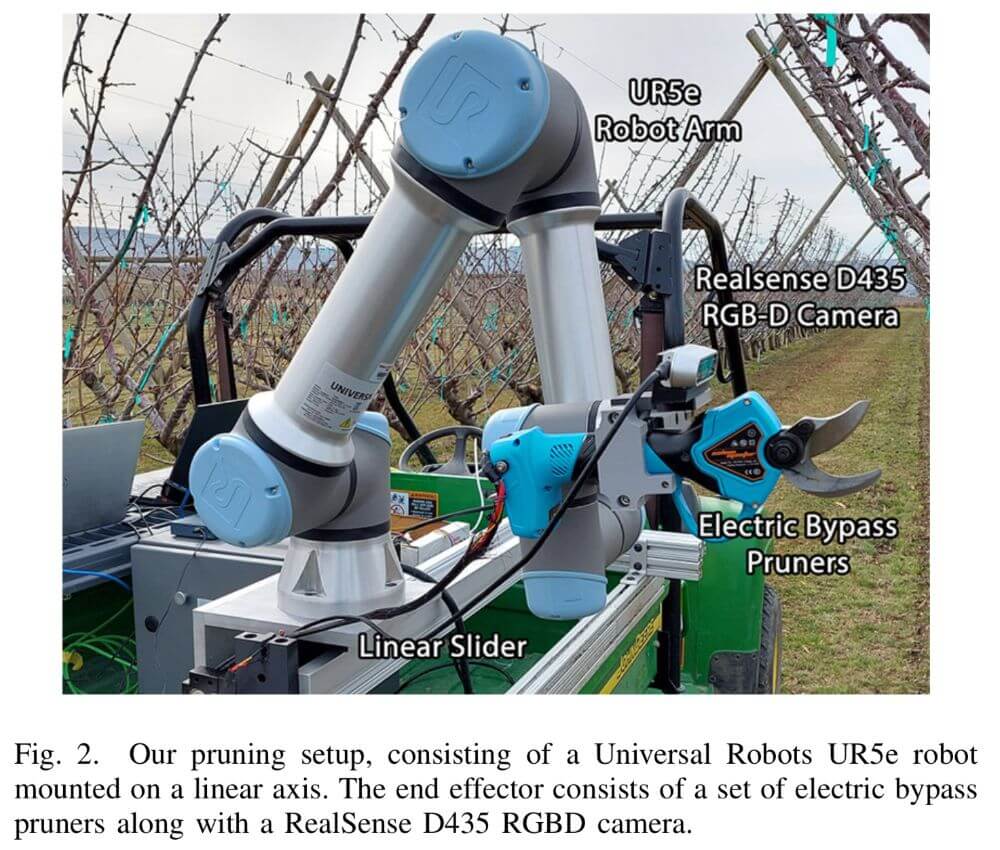

The current research project at the two American universities aims to develop an autonomous pruning system that can be adapted to farming systems with relatively simple pruning rules, such as the Upright Fruiting Offshoot. The integrated system includes a seven-degree-of-freedom robot with an 'eye-in-hand' pruning end effector.

The robot uses online visual feedback and a fully simulation-trained controller to precisely guide the cutting device to the targeted pruning point. The system is capable of operating completely autonomously and requires minimal control of the environment.

The robot's performance has been validated through field trials in a cherry orchard achieving a 58% cutting success rate. Although not fully robust and requiring improvements in productivity, this automated system is the first to operate on fruit trees and represents a useful baseline platform for the near future (You et al, 2022).

Bibliography

R. Ghelfi, A. Palmieri (2022). Planting a new cherry orchard system: evaluation of economic efficiency. ITALUS HORTUS

A. You, N. Parayil, J.G. Krishna, U. Bhattarai, R. Sapkota, D. Ahmed, M.Whiting, M. Karkee, C.M. Grimm, J.R. Davidson (2022). An autonomous robot for pruning modern, planar fruit trees. JOURNAL OF ROBOTICS AND AUTOMATION LETTERS

M. Whiting (2022). Optimizing sweet cherry production efficiencies with mechanization. ITALUS HORTUS

Cherry Times - Tutti i diritti riservati