A biochemistry professor at Texas State University and his students began working about ten years ago on a completely natural method to slow the decomposition process and extend the shelf life of fruits and vegetables.

The work led Dr. Gary Beall, who has since retired from the university, to develop NatuWrap as the flagship product of Nabaco Inc, a San Marcos, TX-based company that produces and currently sells the product primarily to fruit growers in the Pacific Northwest and Spain.

Although Jamie Strachan, a produce industry veteran and the company's CEO, stated that the all-natural solution works equally well on all types of fruits and vegetables.

Beall explained that the patented formulation of NatuWrap consists of several natural components, including earth clay and tree extracts. Since these are natural in origin, the primary ingredients have an inexhaustible supply. The formulation is water-soluble, biodegradable, and the company claims it is safe for human consumption and the environment. It has been certified organic by OMRI (Organic Materials Review Institute) and WSDA. Its water solubility also allows for easy washing.

Beall described it as a “beautifully structured film” that acts as an oxygen barrier, leaving a residue on fruits or vegetables composed of more than 1,000 layers but 20 times thinner than a human hair.

The company’s website states: “Once mixed with water using Nabaco’s proprietary blending systems, the formulas can be added to dip tanks, wash lines, soakers, spray bars, cooling pipes, or misting systems, providing residual protection without affecting taste, texture, or smell.”

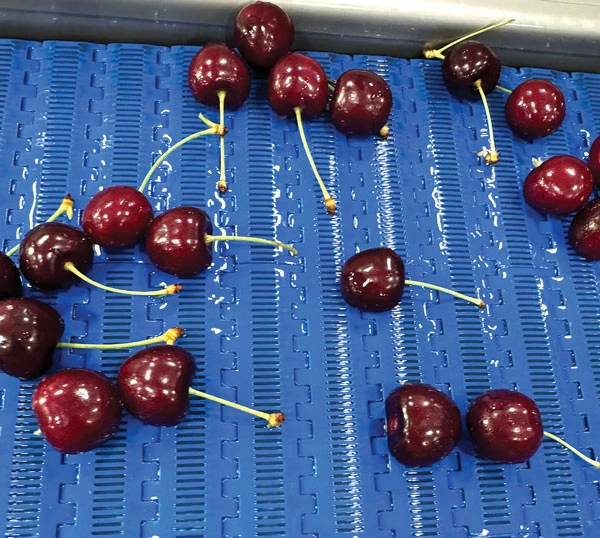

After launching Nabaco, an acronym for Natural Barrier Company, the founders attracted external investors to target “low-hanging fruit,” so to speak, such as pears, apples, cherries, and citrus. These categories of fruit are heavy users of coatings, such as carnauba wax, and grower-packers are familiar with their benefits.

Image 1.

Image 1.

Beall claims that NatuWrap is far superior to wax in many aspects. Most importantly, it significantly extends shelf life. It can also be used to deliver other beneficial post-harvest additives to produce, such as a fungicide. Comparing it to other products, Beall said it is much more effective and easily removed, unlike wax.

He described NatuWrap as “a processing aid” offering additional advantages depending on the fruit. For example, Beall noted that scuffing is a common issue for pears during the washing and packing process. The outer appearance is compromised, and the pears become less appealing to consumers. Beall stated that pears treated with NatuWrap have a far superior appearance after packing and retail display.

Although the shelf life of pears and other fruits is extended by many days, Beall said users can generally expect a doubling of post-harvest shelf life and a 30% improvement in storage and transport quality.

Beall presented a list of fresh produce treated with NatuWrap and highlighted its key benefits. For citrus, the product helps maintain color; for cherries and grapes, NatuWrap keeps the stems greener for much longer, extending their marketability on grocery shelves; for avocados, the skin’s transition from green to black is doubled.

“The simplicity of our organic product lies in the fact that it can be added to water at any point in the production process for any crop, extending storage, shipping, and shelf life while reducing chemicals, plastics, and food loss,” he said, positioning NatuWrap in a category of its own.

Speaking about the product, Strachan said it offers four main benefits. Its physiological attributes top the list. He believes there is no direct comparison to any resin or wax. “NatuWrap acts as a virtual modified atmosphere,” he said. “Applied through water in many different ways, it is a processing aid that significantly extends shelf life by leaving a residue on the fruit that acts as a passive barrier against gases and moisture.”

Secondly, NatuWrap is an outstanding chemical delivery platform for anything the packer wants to apply most efficiently. While it has primarily been used as a post-harvest product, Strachan said it has been commercially tested during growth cycles as an adjuvant to distribute crop protection chemicals more efficiently.

The third and fourth benefits are related to its water solubility, enabling application virtually anywhere, from field to fork. It also allows consumers to wash away residues with tap water. Strachan stated that while NatuWrap has been commercially used mostly for storage fruits, its use on cherries and other fresh produce has proven advantageous across a wide range of categories.

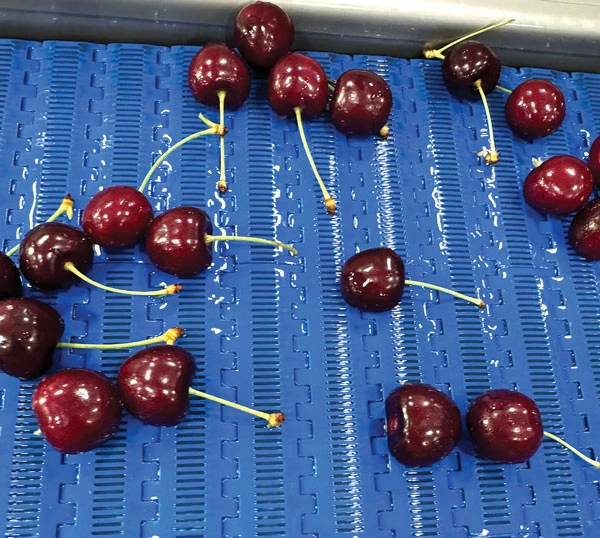

Image 2.

Image 2.

For example, he expects the tomato, banana, melon, and grape sectors to be among the first recipients, as NatuWrap can offer both longer shelf life and a better way to apply other crop protection chemicals, including organics, both pre-harvest and during packing.

He also emphasized the role that NatuWrap can play in the ongoing effort to reduce food waste. Extending shelf life and delaying decay are clearly direct pathways to greater utilization of any fresh produce and a reduction in the amount of harvest ending up in landfills.

Strachan and Beall also discussed the cost of NatuWrap, stating that it is reasonably priced for processors. Many customers are achieving immediate ROI due to reduced fungicide use, cleaning, and repackaging.

Bruce Parkins, operations director of Washington Cherry Growers, based in Wenatchee, WA, recently told The Produce News that the company used NatuWrap on its cherries last season and was very satisfied with the results. “We had a great experience with the product this year,” he said, adding that his team has experimented with NatuWrap over the past three years. “It took a while to figure out how and where to add it to the packaging process.”

Once that piece of the puzzle was solved, they started operating at full speed in 2024. “It basically extended the shelf life of our cherries by six to eight days or more,” Parkins revealed. “The stems stayed green longer, and the fruit looked much better compared to products that had only undergone a chlorine bath.”

The packer experimented with different application rates and found that excellent results could be achieved with a very low application level. They tested levels from 0.5 ppm to 3 ppm and settled on a 0.5 to 1 ppm solution. “At this level, we achieved excellent results with no detectable residue on the fruit.”

Parkins called the cost “very reasonable” and said that reducing waste at the end of reception is a major win.

Read the full article: The Produce News

Image: SL Fruit Service; The Produce News

Cherry Times - All rights reserved