The cherry tree trained using the pergola training system already covers more than 500 hectares in the country. Worldwide, it is found in a dozen countries. This report highlights how it has adopted new techniques, guided by its pioneers.

The training method known as Head System SRP aims to exploit the natural acrotony of the cherry tree to enhance its productivity, precocity, and efficiency in crop management. This system has evolved in recent years by employing the technique of annual or biennial branch breaking, with the goal of achieving constant renewal over time. Today, it is applied to various training systems, such as the central axis, bibaum, multi-axis, and pergola training system.

A detailed description was published in Redagrícola 118 (May/2021).

The methodology involves selecting vigorous branches, which are broken to enable rapid entry into production. Each broken branch, referred to as a “main,” will last no more than three years and will then be replaced by one of the new shoots that emerge after the breakage, ensuring a perpetual level of production.

Each branch should produce 1 kilogram of cherries (100 fruits per branch). Depending on the productive potential of the variety and its planting density, a specific number of productive branches must be maintained to achieve this potential (see the detailed explanation further in the article).

The new approach involves renewing not only through annual branches but ideally through biennial branches, using the so-called “replacement” branches. Until about four years ago, only annual branches were used, requiring a year to enter production after being broken.

Agronomist Marcelo Correa, consultant and producer, observed that by leaving intermediate one-year branches in a vertical position, they could naturally harden and be used the following year to replace the old main branch. Today, one-third of the branches are typically left as replacements each year, to be used for replacing branches that have reached the end of their productive cycle.

Eruption system: striving for precocity

In recent years, there have been interesting developments, as noted by Marcelo Correa, one of the promoters of this system, along with Gonzalo Espinosa, Ronald Vermeulen, and Alejandro Navarro (Image 1).

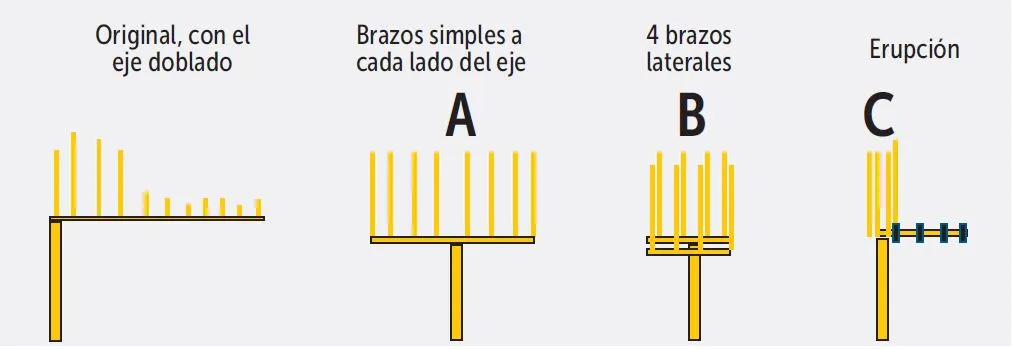

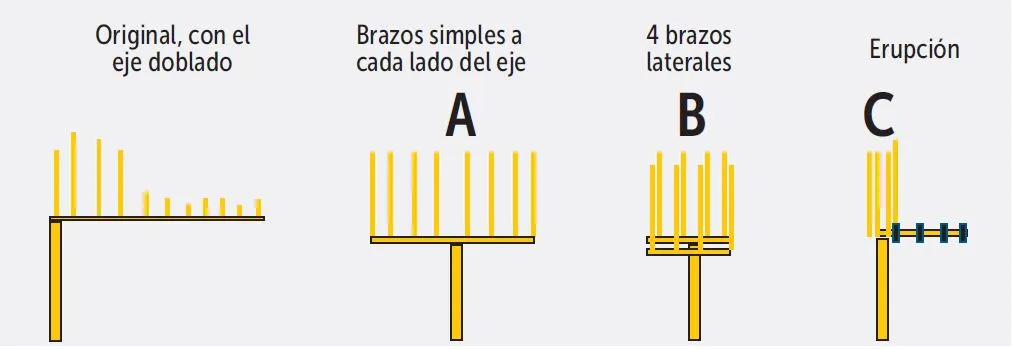

Initially, the practice involved bending the axis during its formation and its productive branches (“original” in Image 2). Later, the technique evolved to form two to four arms, make incisions, and form new branches the following year, taking at least two years to enter production (Image 2 A and B). Today, the process has been accelerated by using finished plants, where the axis is topped, leaving four or five buds that will become the first productive branches after one year.

This system, known as “eruption,” is favored by Marcelo Correa for its rapid entry into production (Image 2 C). Image 2: Evolution of the SRP concept under the pergola training system.

Image 2: Evolution of the SRP concept under the pergola training system.

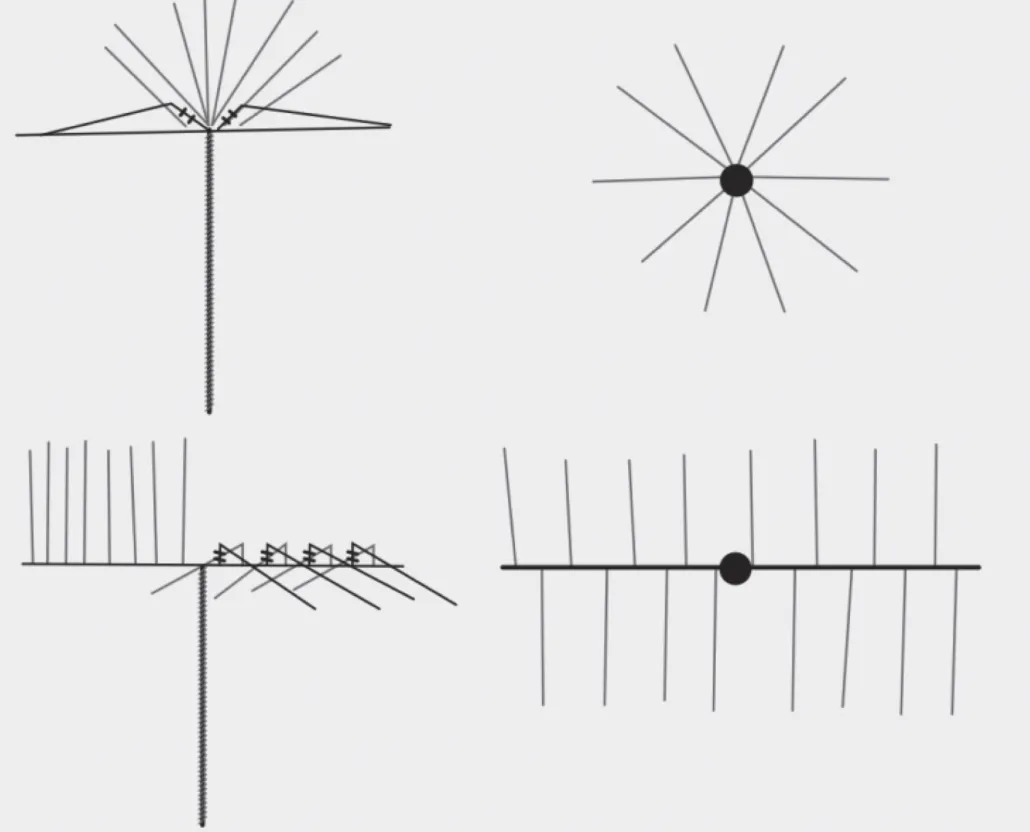

“As soon as the axis is cut,” explains the agronomist, “the option with lateral arms requires first forming them, then making incisions to generate branches that will eventually be broken and produce fruit by the fourth leaf. Conversely, in the case of the circular single-head formation, the branches to be broken form immediately (Image 3). After breaking, the branches harden and are ready for production in the third year.

Image 3: Diagram of a) circular single-head formation (eruption) and b) simple lateral arm formation.

Image 3: Diagram of a) circular single-head formation (eruption) and b) simple lateral arm formation.

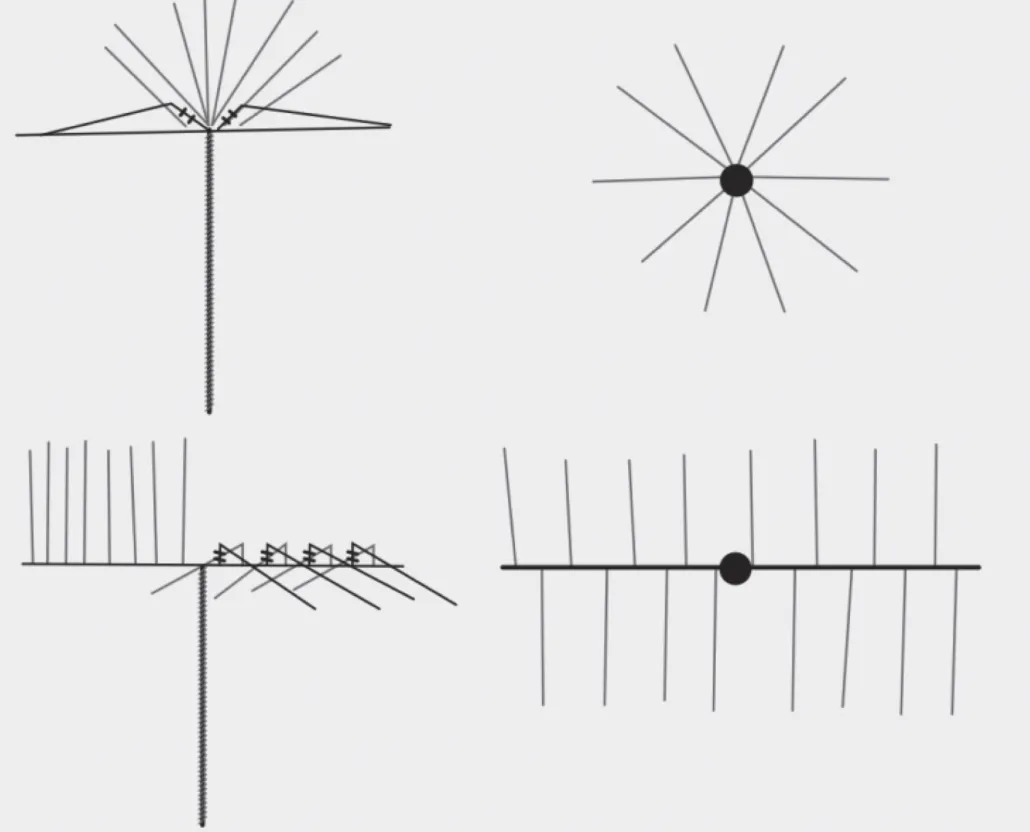

“Since we aim for early production, the eruption system (Image 4) is faster: I plant, cut the axis, and four or five shoots emerge. After one year, I break them all, they harden, and by the third season, they bear fruit. New shoots emerge from the base, eventually reaching the required number of replacements,” he explains.

Image 4: Eruption formation, view from below.

Image 4: Eruption formation, view from below.

Another adjustment involves the height of the trees. Following Ronald Vermeulen’s advice, trees are now trained lower: at a height of 1.80 meters, about 10–15 cm below the wire level. Previously, when the tree head was cut above the wire level, the head’s height increased slightly each year, complicating management over time.

How to determine the number of branches per tree

To determine the number of branches per tree, it is essential to establish the yield target for the variety and calculate it based on the planting density, assigning 1 kg/branch (80 to 120 cherries; 100 on average).

For example, at 4 x 2 m spacing, there would be 1,250 cherry trees per hectare (ha). If the variety is Lapins on Colt rootstock, 16 branches are needed per tree to achieve a potential yield of 20 tons (t)/ha: 1 kg * 16 branches * 1,250 trees/ha = 20,000 kg/ha. If the planting distance were 3 x 2 m, there would be 1,667 trees/ha, requiring 12 branches per tree.

Other varieties may have a lower yield potential, such as 15,000 t/ha, due to precocity or other factors, requiring adjustments to the number of branches (Image 5).

Image 5: MedaTM Bull (IVU-104) variety grafted onto Colt at 4 x 2 m, trained with two axes (bibaum), totaling 1,250 trees but 2,500 axes. The trees' height is 2.1–2.2 m (pedestrian). To achieve 15,000 kg/ha, 6 branches/axis are required: three per side. Here we are experimenting with a formation different from parron, where branches grow in the upper third, known as the “skirt” system. The goal is always to work according to the natural acrotony of the cherry tree.

Image 5: MedaTM Bull (IVU-104) variety grafted onto Colt at 4 x 2 m, trained with two axes (bibaum), totaling 1,250 trees but 2,500 axes. The trees' height is 2.1–2.2 m (pedestrian). To achieve 15,000 kg/ha, 6 branches/axis are required: three per side. Here we are experimenting with a formation different from parron, where branches grow in the upper third, known as the “skirt” system. The goal is always to work according to the natural acrotony of the cherry tree.

Renewal of main branches with replacement branches

The development of the previously mentioned concepts of “main” and “replacement” branches (Image 6) has also marked significant progress, as noted by the interviewee: “I break a vigorous branch, which hardens over one season. The branch fruits over two seasons and is replaced in the third year by a new one, which hardens in one year and then fruits for two seasons, maintaining a perpetual level of production.” This constant renewal requires leaving approximately one-third of branches per tree as replacements.

Image 6: The idea is for the replacement branch to emerge from the base of the main branch and be left in a vertical position for one year. It hardens and becomes productive by the following year, replacing the productive branch that has reached the end of its cycle.

Image 6: The idea is for the replacement branch to emerge from the base of the main branch and be left in a vertical position for one year. It hardens and becomes productive by the following year, replacing the productive branch that has reached the end of its cycle.

Image 7: A future replacement branch starts to emerge from a broken branch.

Image 7: A future replacement branch starts to emerge from a broken branch.

Image 8: Main branches producing cherries.

Image 8: Main branches producing cherries.

Image 9: Annual branch with three alternated vertically growing branches.

Image 9: Annual branch with three alternated vertically growing branches.

As mentioned earlier, the current concept is to use alternatives as elements of renewal. Therefore, if 5-7 regular shoots need to be replaced, the use of alternatives comes into play. Alternatives are annual branches left in the previous year as one-year-old wood at the top of the pergola training system. They should not exceed a length of 1.20 m; ideally, they should measure between 80 cm and 1.20 m. All weak branches must be removed.

If, after completing the number of branches, some shoots (thicker and longer elements) remain, they should never be considered replacements but instead be “topped” at 1-3 basal buds to provide new productive elements for the next year.

“It is important to keep in mind,” warns Correa, “that replacements can reach 50-60% on Colt rootstock, while on Gisela rootstock, they reach 100%. Thus, instead of breaking a one-year-old branch, I break a two-year-old branch with production. If no replacements are available and there is space to fill, one-year-old branches can be broken.”

Another result of the learning process: nowadays, it is preferable to cut rather than break the axis of a newly planted cherry tree. When broken, the newly born branches are not uniform in vigor, whereas cutting results in 4-5 vigorous branches that can be broken the following year.

Image 10: Cherry trees trained using the pergola training system in New Zealand.

Image 10: Cherry trees trained using the pergola training system in New Zealand.

Image 11: Cherry trees trained using the pergola training system in the USA.

Image 11: Cherry trees trained using the pergola training system in the USA.

Image 12: Cherry trees trained using the pergola training system in Hungary.

Image 12: Cherry trees trained using the pergola training system in Hungary.

Questions and Answers

Since this is a relatively unknown management system, naturally there are questions and doubts:

How long do branches remain productive before being replaced?

It depends on the rootstock-branch combination, explains Marcelo Correa. “For example, in Regina on Gisela 6, we leave the rootstock for a maximum of 2 years, ideally 1 year. In Lapins on Colt, broken branches have up to 3 years of useful life.”

How is it possible for a branch connected to the tree for only 10-20% to have the capacity to produce an interesting size?

“I assume it is due to its reserves. I like thick branches because they have more reserve material and ensure that the fruit sizes lean toward the larger end of the scale. That’s why I aim for thick branches as a target.”

Do you produce fruit for only 2 or 3 years using reserves?

“No, a callus forms quickly, and the flow of sap is restored, providing photosynthesis to the plant.”

Does breaking branches increase the risk of pathogens entering the plant?

“We have not observed bacterial cankers or other health problems apart from common ones. However, we must be extremely rigorous in disinfecting the cut and also apply biological products, such as Mamull or others with a similar effect, to prevent wood fungi from entering.”

Are there specific conditions to follow to avoid failure?

“In addition to careful sanitation, as mentioned earlier, vigorous trees are necessary. Otherwise, they will not support the branch-breaking method.”

What are the additional costs for the structure?

“In the first year, we install the head on both sides of the row, intermediate poles, and wire 17/15 at the desired height. The entire vineyard costs around $4,500-5,000 per hectare. Unlike table grape vines, which can support up to 50 tons per hectare, this vineyard doesn’t bear as much weight because the broken branches lignify and become self-supporting. You can make a light vineyard".

"The wires are primarily used to tie the shoots together. If the cost is $5,000 and you can get $4 per kilo, we’re talking about 1,250 kilos per hectare. With the system’s precocity, this aspect doesn’t matter much. On the other hand, if you plan to use a variety superior to Gisela, in this case, the only added cost is the perimeter.”

Are there disadvantages to the SRP bush system?

“I have observed more double fruiting due to the effect of the sun, which reaches the branches 100% thanks to their horizontal position. So far, this has not been a significant problem, but I will quantify it this year. The most concerning aspect is that on broken branches in a horizontal position, the level of browning is very high, and those spurs do not sprout again.”

"As a result, it is possible that some level of over-fruiting may occur in varieties like Lapins/Colt. Although the size distribution has been good, I want to further improve the size of the fruits, so this year I did some “Chinese thinning.”

Of the 8 flower buds for each vegetative bud, we left 2 to 4, removing the rest, which had 35-40 days/ha of swollen buds. In Santina, this does not happen, and in IVU-115, photo 8. Brown cherry in a) New Zealand, b) USA, c) Hungary, and d) Netherlands. On the contrary, to increase fruit set, I apply Retain, auxins, and pollen (Benton variety) using electrostatics, in addition to using 10 hives/ha.”

Finally, Marcelo Correa summarizes the numerous advantages he sees in the SRP bush system: larger fruit size, sweetness, and firmness of the fruits; efficient pedestrian harvesting (300 kg/person/day); early production; optimal lighting; expression of varietal productive potential; mitigation of frost damage; provision of young fruit spurs; simple pruning; easy weed control; and great flowering uniformity thanks to the application of cyanamide alone in years with few cold hours.

“The key is that using this system allows us to combine engineering with agronomy, utilizing the necessary and effective productive material to achieve a quality final product,” he states.

Source: Redagrícola

Images: Redagrícola

Editorial staff Redagrícola

Cherry Times - All rights reserved