At the peak of the harvest season, when the work pace in orchards accelerates and every minute counts, a crucial stage of the process is often overlooked: field storage, while the fruit awaits transport to the processing and packing facility.

Although the importance of careful harvesting and rapid cooling is well known, the time between these two steps—those critical hours under the sun or in the shade—can make all the difference in the final condition of the fruit.

The Experimental Study

In this context, with the aim of evaluating how humidification systems might affect weight loss and the quality of cherries temporarily stored in the field, a trial was conducted in a commercial orchard in the Buin area, Metropolitan Region of Chile.

The study focused on four commercial varieties: Santina, Bing, Lapins, and Sweetheart, applying the same experimental design to each variety to obtain comparable results.

Four Treatments, One Key Question

The experimental design combined two harvest times (morning and noon) with two storage conditions (with and without humidification), for a total of four treatments, all applied following a common protocol.

The freshly harvested fruit was stored in field collection centers: one traditional, covered with Raschel netting, and one modified, equipped with a high-pressure humidification system and double Raschel netting to retain humidity.

The fruit remained in these centers for five hours before being transported to the processing facility, where it was hydrocooled, packed in modified atmosphere bags, and stored in cold rooms at 0°C for 30 days.

At each stage—from field storage to the end of cold storage—the following were monitored: fruit weight, pulp temperature, environmental conditions, and fruit condition.

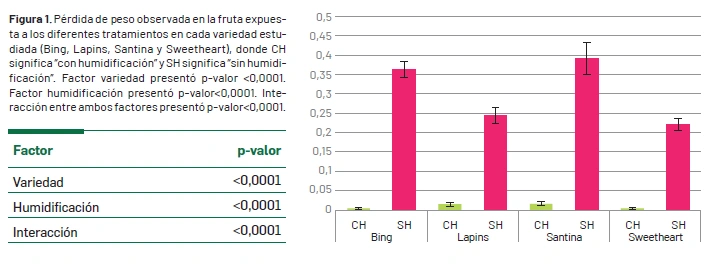

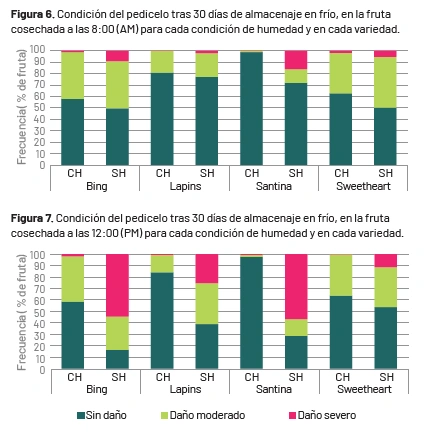

Figure 1. Weight loss observed in fruit under different treatments for each studied variety (Bing, Lapins, Santina, and Sweetheart), where CH means “with humidification” and SH means “without humidification”. The variety factor had a p-value <0.0001. The humidification factor had a p-value <0.0001. The interaction between both factors had a p-value <0.0001.

Figure 1. Weight loss observed in fruit under different treatments for each studied variety (Bing, Lapins, Santina, and Sweetheart), where CH means “with humidification” and SH means “without humidification”. The variety factor had a p-value <0.0001. The humidification factor had a p-value <0.0001. The interaction between both factors had a p-value <0.0001.

High Humidity, Less Dehydration

The results were clear: cherries stored in conditions of high relative humidity showed significantly less weight loss due to dehydration (Figure 1), especially in the noon harvest, when temperatures and vapor pressure deficit (VPD) are higher.

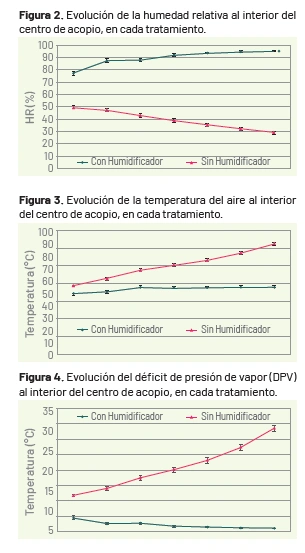

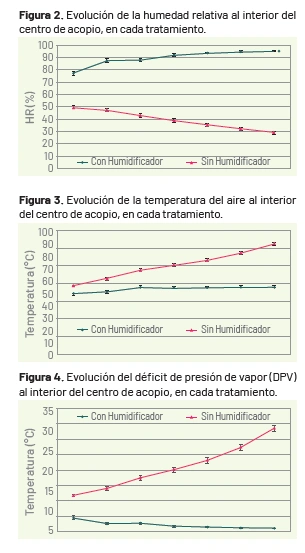

During the observation period, the humidification system maintained an average relative humidity of 90%, compared to 39% recorded without humidification (Figure 2).

Additionally, a reduction in air temperature was observed inside the humidified center (Figure 3), which remained consistently below 20°C, while in conventional systems it exceeded 30°C.

This difference led to a lower VPD in the humidified center (Figure 4), resulting in less weight loss from harvest to packing.

In the treatments without humidification, fruit lost significantly more weight compared to those stored in controlled humid environments.

Figure 2. Evolution of relative humidity in the collection center for each treatment. Figure 3. Evolution of air temperature in the collection center for each treatment. Figure 4. Evolution of vapor pressure deficit (VPD) in the collection center for each treatment.

Figure 2. Evolution of relative humidity in the collection center for each treatment. Figure 3. Evolution of air temperature in the collection center for each treatment. Figure 4. Evolution of vapor pressure deficit (VPD) in the collection center for each treatment.

Long-Term Effects

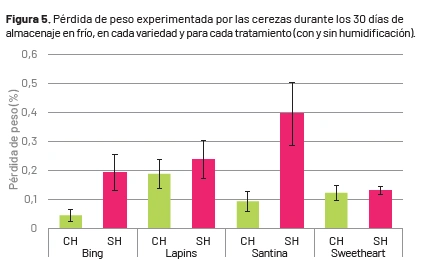

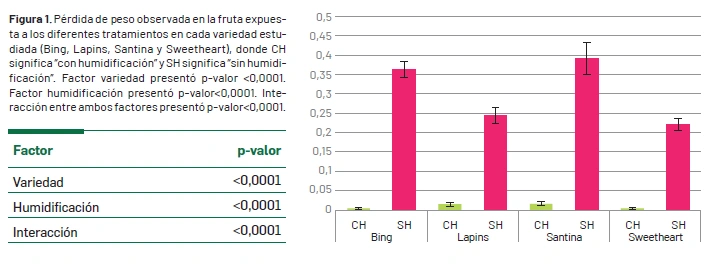

This trend continued even after 30 days of cold storage. Although absolute losses were smaller at this stage, cherries previously subjected to humidification showed better results, with significantly lower weight loss compared to those stored without humidification (Figure 5).

This demonstrates that good humidity control in the early stages has a lasting impact throughout the entire post-harvest chain.

Figure 5. Weight loss experienced by cherries during 30 days of cold storage, by variety and treatment (with and without humidification).

Figure 5. Weight loss experienced by cherries during 30 days of cold storage, by variety and treatment (with and without humidification).

Final Condition Also Improves

In addition to weight loss, the fruit’s condition after 30 days of storage was evaluated, with particular attention to the stem appearance, incidence of rot, cracks, and “lizard skin”.

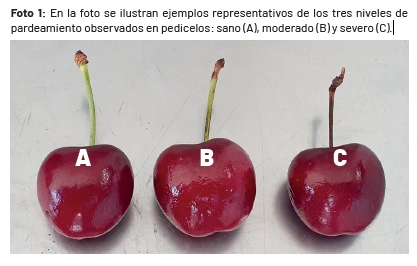

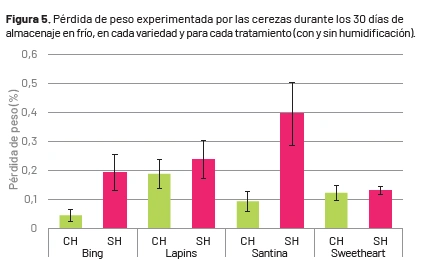

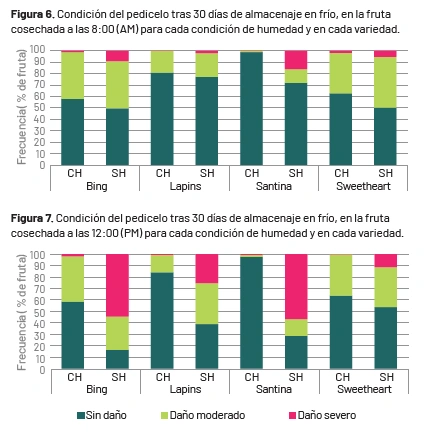

No statistically significant differences were found in rot, cracking, or lizard skin, but better stem condition was observed in humidified cherries, especially those harvested at noon (Figures 6 and 7).

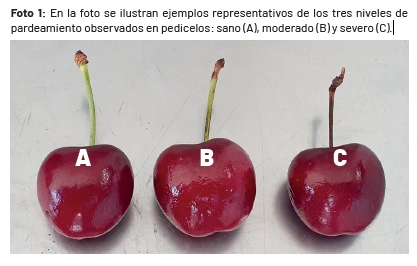

“Stem condition” refers to the level of visible browning: a green, turgid stem indicates freshness; a moderately damaged one shows signs of dehydration; while severe damage results in pronounced browning, indicating significant water loss shortly after harvest.

The green and intact stem is one of the key visual indicators of freshness for consumers. Preserving its appearance—even after 30 days—is a clear commercial advantage.

Photo 1: Representative examples of the three levels of browning observed in the stems: healthy (A), moderate (B), and severe (C).

Photo 1: Representative examples of the three levels of browning observed in the stems: healthy (A), moderate (B), and severe (C).

Paradigm Shift in Field Management

The results of the study lead to a clear conclusion: managing environmental conditions during field storage is not a detail, but a strategic tool for preserving cherry quality throughout the post-harvest chain.

Until now, most efforts have rightly focused on optimizing in-plant cooling, shortening transport times, and improving handling conditions.

These advancements have been key to elevating the international quality standards of Chilean cherries.

In this perspective of continuous improvement, the study suggests that integrating humidification systems in collection centers can be a valuable addition.

Implementing them would help reduce weight loss and maintain fruit appearance from the very first stages, without requiring complex operational changes.

Figure 6. Stem condition after 30 days of cold storage in fruit harvested at 8:00 AM, by humidity condition and variety. Figure 7. Stem condition after 30 days of cold storage in fruit harvested at 12:00 PM, by humidity condition and variety. Color legend: Dark green: No damage - Light green: Moderate damage - Fuchsia: Severe damage.

Figure 6. Stem condition after 30 days of cold storage in fruit harvested at 8:00 AM, by humidity condition and variety. Figure 7. Stem condition after 30 days of cold storage in fruit harvested at 12:00 PM, by humidity condition and variety. Color legend: Dark green: No damage - Light green: Moderate damage - Fuchsia: Severe damage.

Adopting this technology can be a strategic investment for producers who aim to optimize cherry quality from the start, especially during hot seasons or midday harvests.

Post-harvest begins not at the processing facility, but in the field, the very moment the fruit is picked from the tree.

Text and cover image source: Mundoagro

Valentina Vesely and Sebastian Johnson

Johnson Industrial Project, Mundoagro

Cherry Times - All rights reserved