Every time I visit a cherry packing line, I am once again amazed by the enormous work and technology required to get the right fruit into the right package and deliver it to the right customer within a day or two, at the highest price.

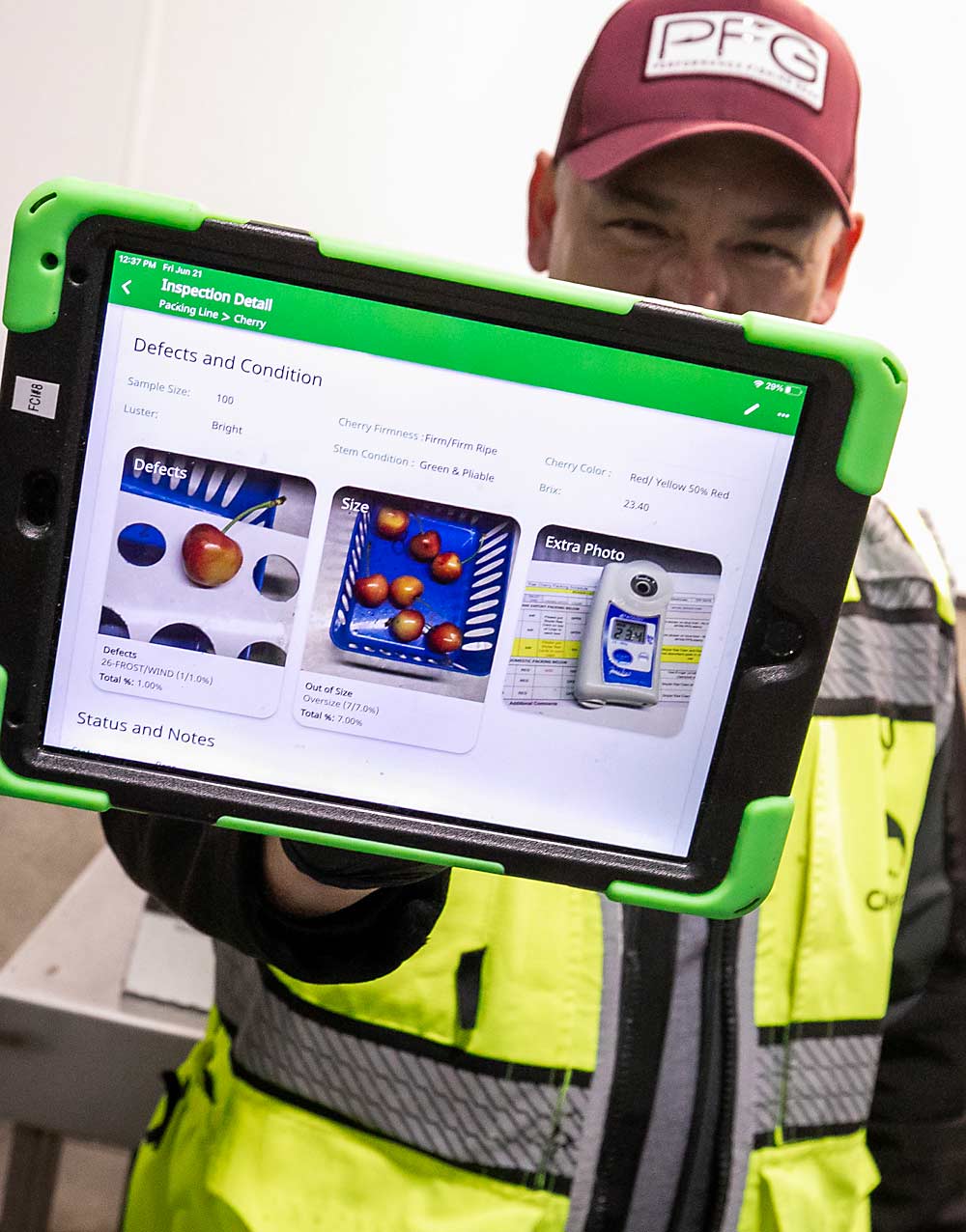

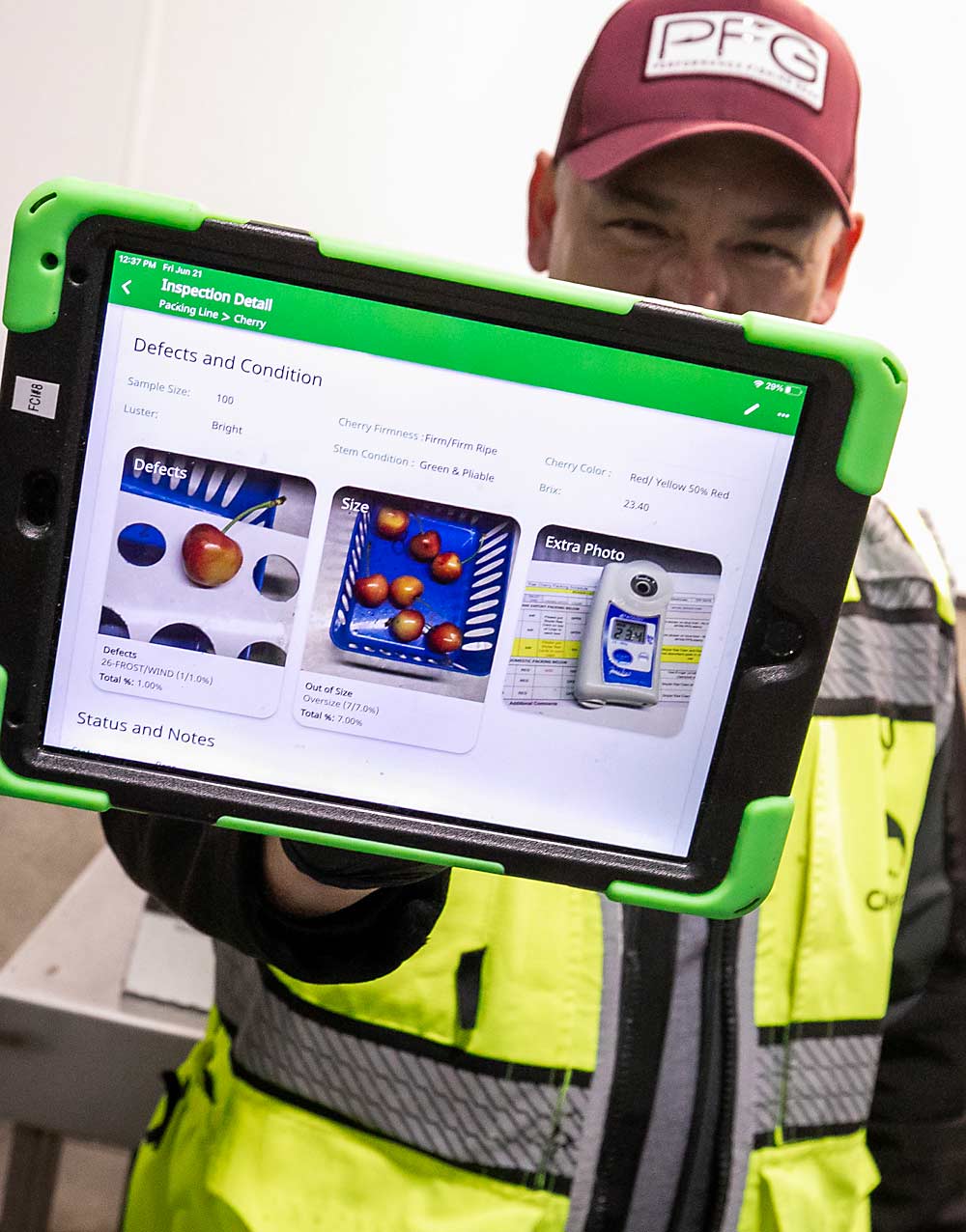

The integration of digital data tools is helping Columbia Fruit Packers manage the chaos of the cherry season more efficiently. At every stage of a cherry's journey through the plant, from receipt to packaging out, employees with colorful tablets enter quality data and take photos for documentation into a data management platform developed by AgroFresh.

“During the cherry season it is crucial,” said Isaac Balderas, production manager at the Wenatchee, Washington-based company. “It’s real-time feedback when our operators take samples.”

The most intelligent data management tools are being offered to fruit companies, from orchard to warehouse, coming from long-standing suppliers like AgroFresh and new startups like Terrantic. It is an ambitious goal, but fruit companies report finding value in packaging-focused platforms.

“Different packaging companies are at different stages of digitalization,” said Jon Cox, vice president of the scientific and technological sector at Double Diamond, a Quincy, Washington-based packaging company. He recently collaborated with Terrantic to consolidate the company's quality control and storage data into one place, increasing operational efficiency. “They met us where we were and are taking us to the next stage.”

The problem is not a lack of data. In fact, packers have so much data that they need these new tools to make sense of it all.

“It’s about managing how the right people get the right data,” said Emily Gant of AgroFresh during a workshop organized by the company. The company's FreshCloud tool is simple for line users and customizable for each operation. “We can work with you to set up the right type of alerts and ensure they reach those who need to know, so decisions can be made.”

The Difference of Digital Data

At this point, FreshCloud is not a technology that saves labor but saves Balderas the time previously spent searching for information on paper sheets around the facility.

Now, if the quality control personnel on the line count too many good cherries ending up in the bin, for example, or too many cherries passing through despite a defect difficult to detect, such as a rough skin caused by frost, the technology flags the data so that the optical sorter can be adjusted for the fruit batch before it’s too late.

In the control room, large screens display each batch of fruit being processed that day, with a color-coded alert system.

“Operators can see the receipt, the grading of the ladies, the samples to be culled, everything is connected,” said Balderas during a June visit. “With paper, by the time we realized we had a problem, it was too late to intervene.”

The benefits of data digitalization extend beyond the cherry season.

“We have an abundance of information, but it doesn’t always reach the people who need it,” says Kelli Canterbury, quality control manager at Blue Star Growers, a pear packing cooperative in Cashmere, Washington. “Every shift delivered paper inspection sheets. It was a kind of disorganized chaos.”

For pear and apple packers, FreshCloud connects inventory data with incoming orders, said Gant. The platform offers some predictive analytics and also integrates with Croptracker’s inventory and traceability tools. “The goal is to eliminate food waste. We want to put the right fruit in the box, and the more we can work with customers to plan ahead, the more likely the fruit will arrive in the right box on the first try,” she said.

From Models to Plans

Terrantic, a new tech startup in Seattle, is building data analysis and management tools tailored for fruit packers.

It develops algorithms that create a mathematical model of the packing process and provides a dashboard to visualize the process and simulate the effects of any changes. This has helped Double Diamond find efficiencies in apple packing, said Jon Cox (not related to Trevor). Previously, the production assistant spent a lot of time tracking this information from multiple systems during meeting planning. Now, the job is easier.

Terrantic also plans to simplify the work of the production manager, as its data analysis tools interpret the data and make recommendations. “It’s a very interesting concept to have order and inventory data and generate a packing plan,” said Jon Cox. “We’re excited about this possibility, but before I just had to make the spreadsheets talk.”

Read the full article: Good Fruit Grower

Images: Good Fruit Grower

Cherry Times - All rights reserved