The choice of the training system can substantially influence the effectiveness of harvesting techniques whether they are manual or automated. The increasing costs associated with manual harvesting of stone fruit have prompted the exploration of mechanical alternatives for this process, especially for varieties grown for processing purposes.

Studies conducted in this regard have shown the significant influence of tree architecture in this context. However, mechanization of the harvesting process of fruits is still an unsolved problem.

The main objective of the experiment conducted at the Department of Pomology of the National Institute of Horticultural Research (Poland) was to develop a new form of breeding and to evaluate the adaptability of horizontally formed trees with a "Y" canopy for mechanical harvesting of sour cherries and sweet cherries..

This was done by comparing them with standard spindle trees, which requires manual fruit picking. In 2014, sour cherry and sweet cherry trees were planted. The trees were spaced 4.5 meters between rows while the spacing within each row varied from 1.5 to 2.5 meters depending on the specific cultivar.

The trees were deliberately grown in a configuration resembling the letter "Y," in which the branches were strategically inclined 20° or 30° from the horizontal plane. This specific arrangement was designed to facilitate mechanized harvesting of fruits suitable for consumption after processing, using a tractor-mounted harvesting apparatus.

A comparison was conducted between two canopy construction systems, each with different degrees of shoot inclination, and the standard spindle. The start of mechanical fruit harvesting occurred three-year after planting, facilitated by a specially designed harvester at the Institute of Horticulture in Skierniewice, Poland.

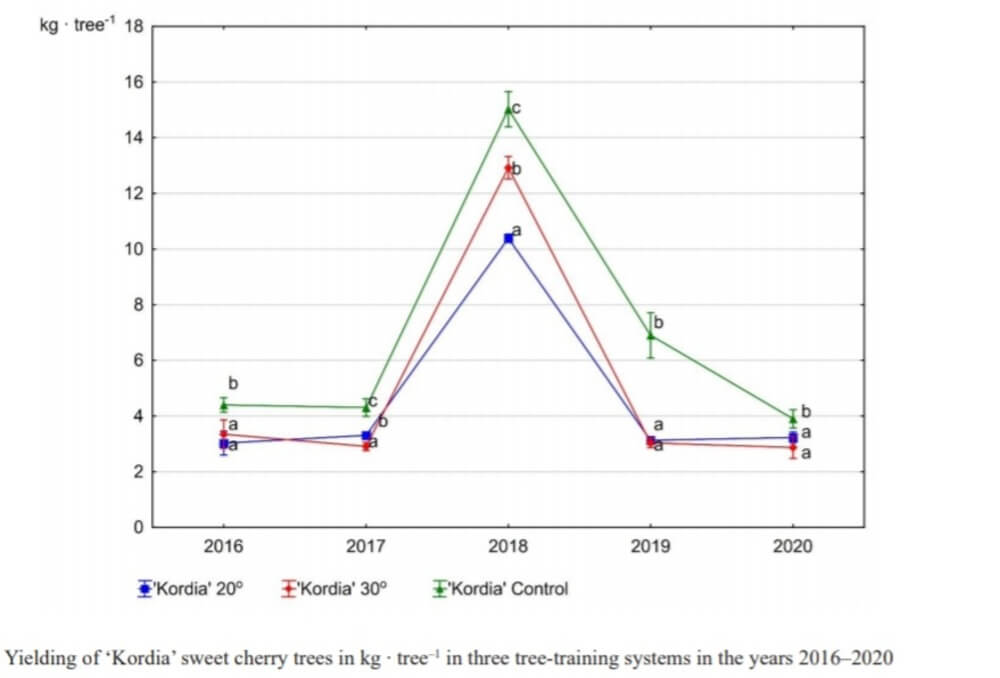

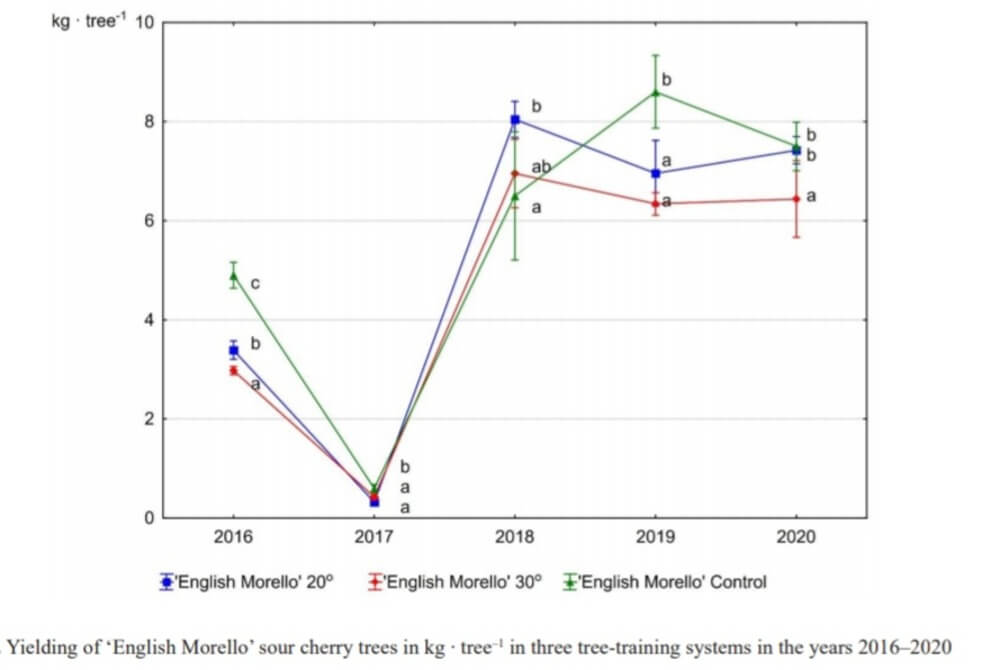

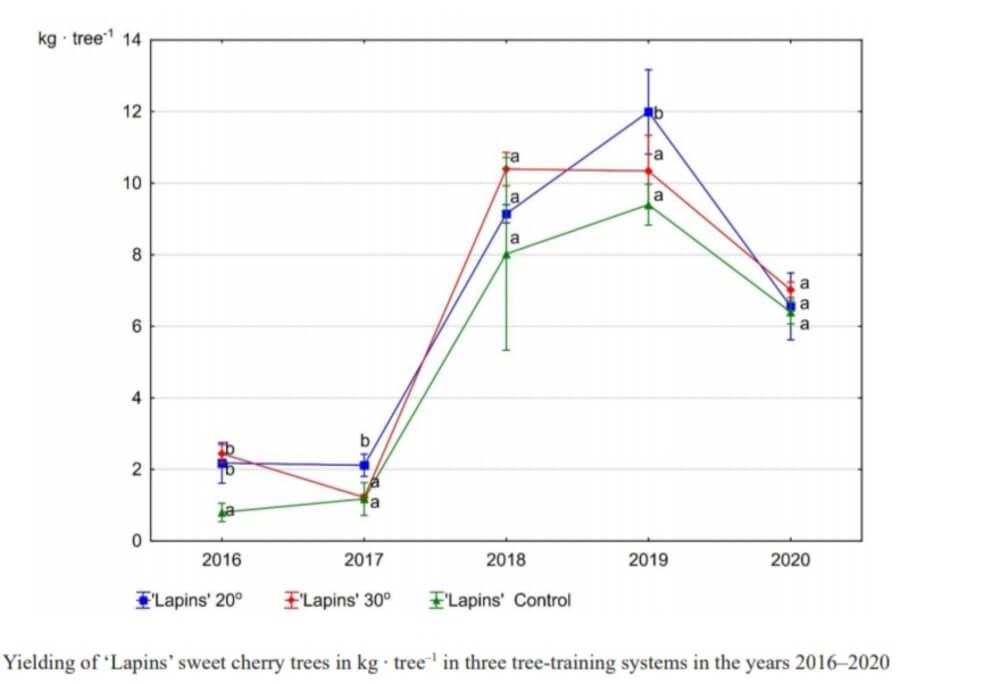

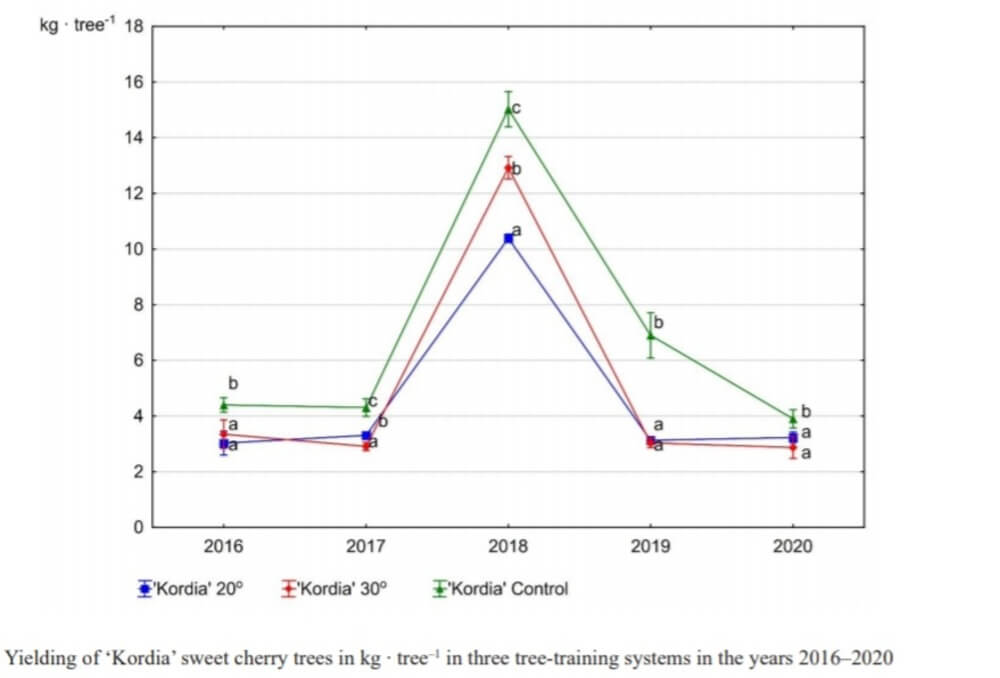

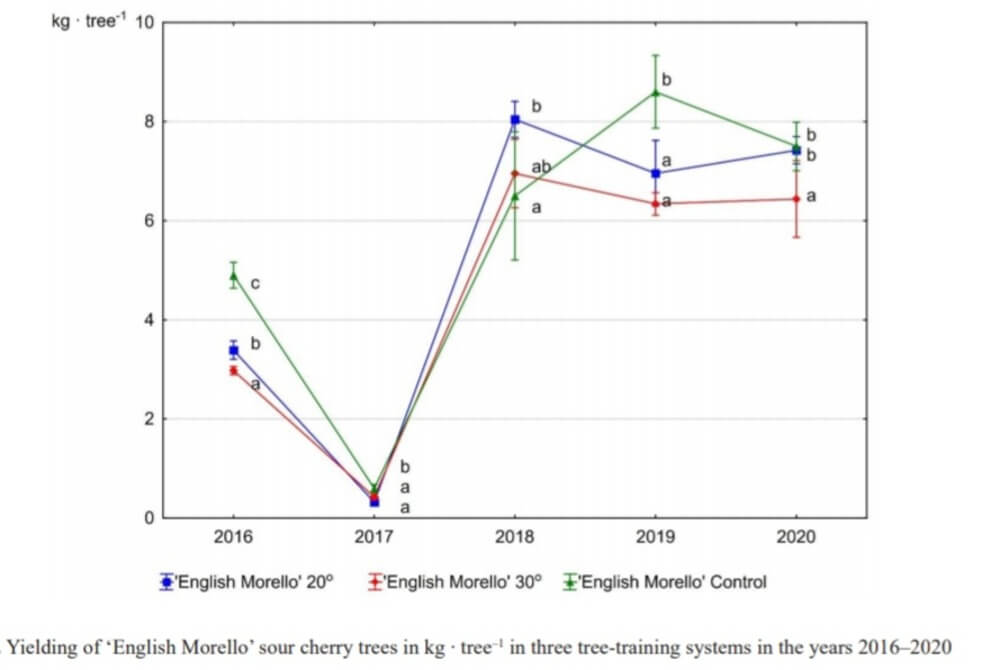

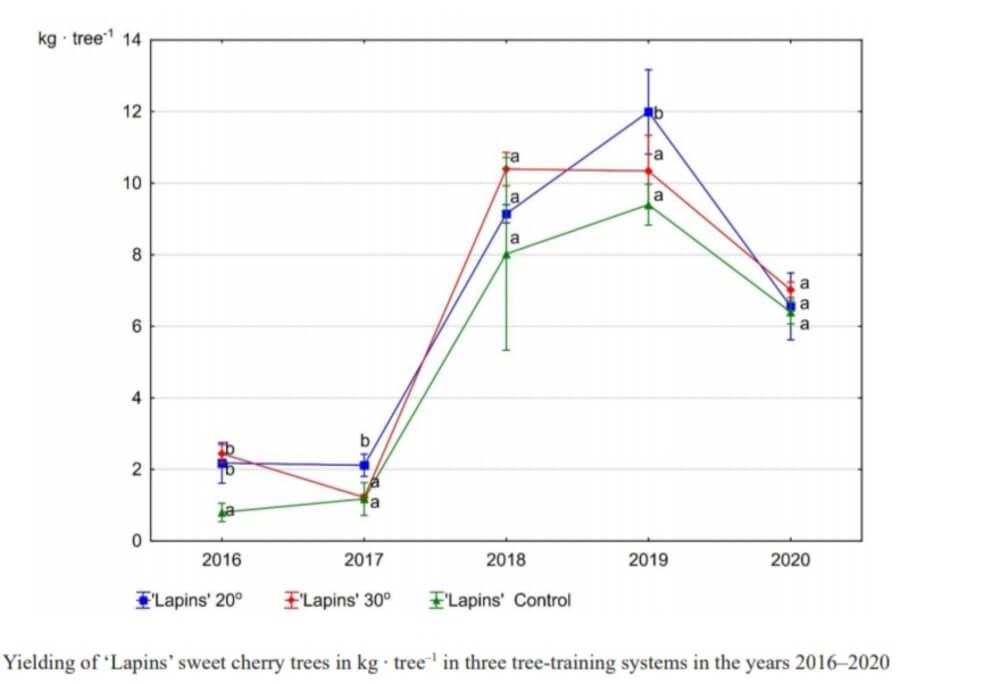

Clearly, productivity rates per plant were influenced by the typical weather conditions of each season. As an example, during season 2018 the productivity ranged from 5.3 to 9.2 kg per tree for sour cherry trees, and from 8.0 to 15.0 kg per tree for sweet cherry trees. Due to the extremely abundant production of trees of all cultivars, the mechanical harvest accomplished 60–70 times greater productivity per hour.

"Y"-shaped trees showed similar yields, but also higher and lower yields, depending on the specific cultivar, compared to spindle-grown trees. A first conclusion of this study is that the cultivation of sour cherry and sweet cherry trees with a horizontal Y-shaped canopy configuration, with shoots inclined at 20° or 30° to the horizontal plane, offers practical advantages for efficient fruit harvesting by mechanical means.

The second conclusion is that not all varieties respond in the same way. This study found that the cultivars 'Debreceni Botermo,' and 'Lapins,' trained at horizontal Y-shaped canopy with shoots inclined at 20° or 30° to the horizontal plane, showed fruit yields comparable to or higher than those of trees with a spindle-shaped canopy.

Source: Buler, Rabcewicz, Bialkowski, Comparison of the yielding of plum, sour cherry, and sweet cherry trees trained to a trellis for mechanical harvesting of fruit with those trained to a leader, The National Institute of Horticultural Research, Skierniewice, Pomology Department, Konstytucji 3 Maja 1/3, 96-100 Skierniewice, Poland.

Melissa Venturi

University of Bologna (IT)

Cherry Times - All rights reserved