ADVERTORIAL

In November 2022, TOMRA Food and ICOEL S.r.l. reached an agreement that defines ICOEL as TOMRA Food's integrated business partner for Europe and preferred partner for cherry technologies in Latin America. This agreement exploits the synergies between the two companies to strengthen the sales, services and support provided to ICOEL's customers and those of TOMRA Fresh Food (a division of TOMRA Food).

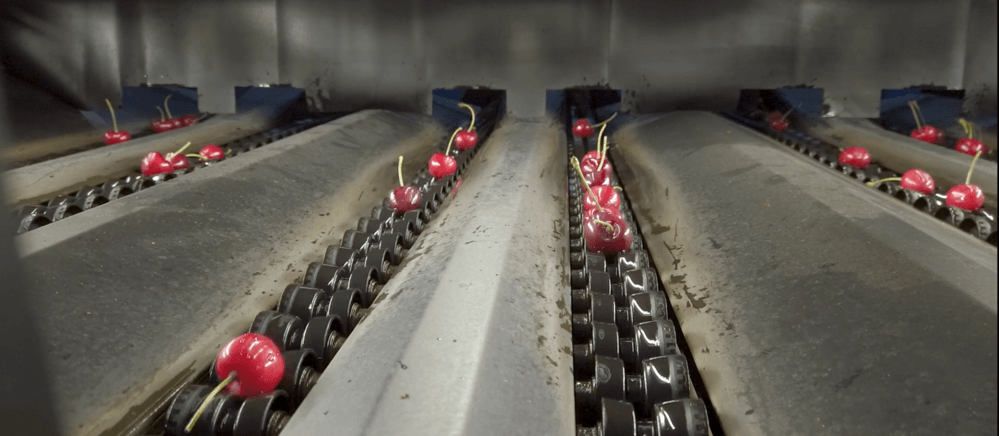

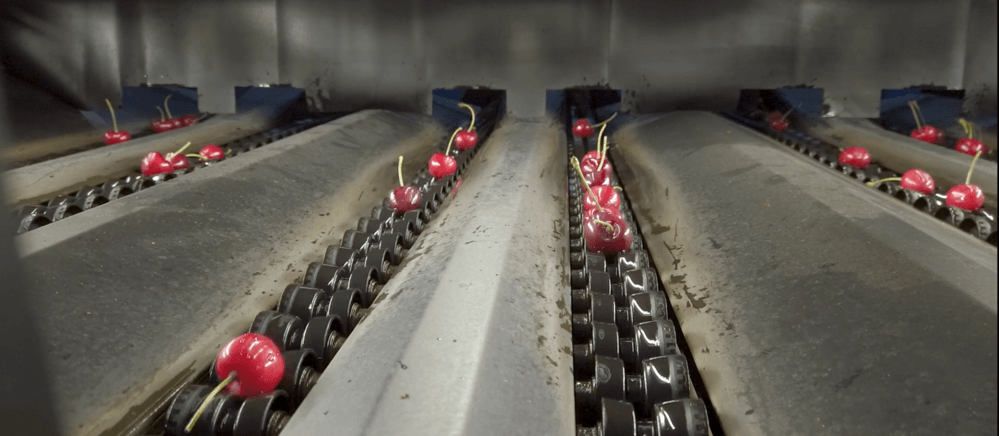

TOMRA Food designs and manufactures sensor-based grading and peeling solutions. ICOEL designs and manufactures solutions for processing, sorting, packaging and traceability of fruit and vegetables. TOMRA Food and ICOEL's machines are often used in the same processing and packaging plants, especially in Europe.

In this double interview, Benedetta Ricci Iamino, Global Cherry Category Director Tomra and Bruno Stravato, General Manager, ICOEL, talk about the importance of this partnership for cherry packers.

How important is Italy for TOMRA's cherry category? Can the partnership with ICOEL help in this respect?

Benedetta Ricci Iamino: Italy is definitely one of the most important markets for TOMRA Food's cherry category and will remain our main focus. Thanks to our strong partnership with Icoel in recent years, more than 50% of the electronic grading systems in the country are from TOMRA. We expect to increase this number in the next two years, thanks to the growing interest in our technologies from Italian customers, who know they can rely on TOMRA and ICOEL to take care of their cherries.

Benedetta Ricci Iamino, Global Cherry Category Director (Tomra)

Benedetta Ricci Iamino, Global Cherry Category Director (Tomra)

Bruno Stravato: Italy, with its fifth place and 18 varieties of cherries, remains one of the most important producers on the international market. Particularly in certain areas such as Apulia, Campania, Veneto and Emilia, there are areas where there is a strong vocation in the production of cherries; suffice it to say that south of Bari, about 100,000 tonnes are produced annually.

With these figures in hand, it is easy to understand how the demand for processing plants with state-of-the-art technology, capable of sustaining the pace of demand in this market, is very high. With a scenario like the one we have just presented, Italy, where we already have profitable and long-standing partnerships, remains of fundamental importance to us. In addition, with the cutting-edge technologies offered by TOMRA for calibration, the proposed solutions provide the integration that all manufacturers require for their plants.

Bruno Stravato, ICOEL

Bruno Stravato, ICOEL

Which countries do you intend to focus on the most?

Ricci Iamino: TOMRA Food works in more than 80 countries with over 12,000 processing plants for all types of fruit and vegetables. As far as cherries are concerned, TOMRA Food has always focused on providing its grading and packaging solutions in the countries of major production and export, such as Turkey, Italy, Spain, North and Latin America and Oceania. In these countries, thanks to partnerships such as the one with ICOEL, Tomra has already installed both grading and automatic packaging systems in over 500 fruit and vegetable plants.

TOMRA Food wants to grow together with its customers; that is why the focus in the coming years will be on implementing an increasingly strong service and after-sales service in countries where we are already present and, at the same time, implementing a widespread sales network in new cherry producing and exporting countries such as Uzbekistan, South Africa and Asian countries.

Stravato: The starting point for this partnership was South America, in particular Chile, the first among cherry producers. But also Italy as we explained before, Turkey and Greece are countries we are already focusing on.

The cherry market is an ever-expanding market with an increasing presence in countries such as South Africa and Europe in general.

Can you explain TOMRA and ICOEL's approach to the cherry industry?

Ricci Iamino: Every year, during each cherry season, whether in the northern or southern hemisphere, TOMRA sends a team of experts to the world's major cherry production areas, working closely with customers to understand how to help them improve yields, minimise waste, lower labour costs and find answers to ongoing challenges, future market needs and increased quality requirements. For TOMRA, cherries are constant work 360 days a year, and thanks to the willingness of our customers, we are constantly improving and innovating new technologies for grading cherries.

Stravato: The foundations of this relationship are laid on the importance of the role played by the customer throughout the process, from the design to the commissioning of the installation. The added value also lies in training and technical assistance, which are essential to enable our customers to work independently, being fully aware of the strengths of the technologies installed.

The strong synergy with TOMRA gives the customer the right security to facilitate the choice process and streamlines the after-sales relationships that really make the difference for us. Working together sharing a vision of the market and objectives makes the presence of both companies more effective in markets that are characterised by different dynamics each time.

What is the comparative difference between TOMRA, ICOEL and its competitors?

Ricci Iamino: TOMRA invests around 8% of its annual turnover in research and development. Thanks to this massive contribution in terms of expertise and resources, we have been able to provide a higher level of technology than is available on the market. We believe that one of our main advantages is that our technology is able to classify the product better, with more accurate calibration. This can help customers increase their profits by being able to sell bigger cherries better. At the same time, we have a very customised system that allows us to select different qualities and different categories of gauges for different customers and markets.

Finally, we have invested heavily in helping customers reduce labour costs by maximising line efficiency, increasing kilos per hour and using the same number of people, if not fewer. This allows for a much simpler operating system for cleaning and maintaining processing lines, resulting in lower costs over time than other systems available on the market.

Stravato: The substantial difference lies in the ability to work together to achieve more ambitious goals. In a dynamic scenario such as ours, where the key pawn is technological innovation, a relationship such as the one established between ICOEL and TOMRA brings together the skills and knowledge of both in the study and implementation of solutions that fully meet customers' requirements.

Working in synergy allows us to achieve higher quality standards than our competitors.

The high degree of specialisation of both parties gives us the opportunity to pay more attention to the customer at every stage; design in particular benefits from this collaboration, the complexity inherent in this first step is reduced.

The combination of both in the subsequent phases of realisation, testing and processing, emphasises the advantages that can be summarised as a reduction in development time, an increase in product quality and certainly a reduction in the inefficiencies typical of longer and more complex processes, resulting in an increase in customer satisfaction.

What are the benefits for the end customer of the partnership between TOMRA and ICOEL?

Ricci Iamino: Everything revolves around the customer. Both TOMRA Food and ICOEL have a customer-focused culture, and by working together, they have the opportunity to improve the efficiency and service of their processing lines. Now that ICOEL is an integrated business partner of TOMRA, we follow the same processes and share information and resources.

Sales and customer support for both companies' machines will now come from a single source, making life easier for end customers thanks to a 'one-stop shop'. This alliance will also give TOMRA Food and ICOEL greater leverage in the implementation of major projects.

Customers using TOMRA Food and ICOEL processing lines will receive comprehensive and integrated service support for both brands from both TOMRA and ICOEL. To facilitate this new agreement, TOMRA Food is expanding its team in several countries, while some TOMRA functions have been integrated into ICOEL.

Stravato: Certainly, a collaboration of this kind brings together the know-how of two different and complementary companies capable of merging their state-of-the-art ICOEL - TOMRA technologies into a single solution.

Technological integration, thanks to the intercommunication of the various stages, speeds up the machining processes and optimises them, resulting in a management integration of the systems.

The customer thus interfaces with a single reality that guarantees a linear relationship and faster responses throughout the design and implementation process.

Contact Tomra:

Web Email

Contact Icoel:

Web Email

Cherry Times - All rights reserved