Colour, size, shape and texture of the fruit are important quality factors that can significantly influence the final quality of the product. Before marketing, the fruit is sorted and companies are always looking for non-destructive and fast tools for this. Visual methods are interesting because they can measure the critical quality characteristics of colour and shape.

The Computer Vision System (CVS) is an artificial intelligence used to diagnose, separate and classify both fruit and vegetables. It is a fast, non-destructive and reliable method that can extract a lot of information about the physical and chemical characteristics of fruit. In recent times, there have been significant improvements in imaging technologies and their analysis, which have increased the accuracy and efficiency of Computer Vision Systems.

In cherry, the colour of the fruit skin is a vital indicator of its ripeness and quality, influenced by the concentration of anthocyanins and the ratio of total soluble solids to total acidity at harvest. Sweet cherries are susceptible to environmental factors, especially changes in temperature, and rapidly lose their quality after harvest and during transport and storage.

Sweet cherries can suffer post-harvest quality loss such as loss of firmness and acidity, petiole drying, skin browning and fungal diseases. Active packaging and fruit coating treatments are crucial technologies that release active ingredients to protect products from microbial degradation and increase their shelf life.

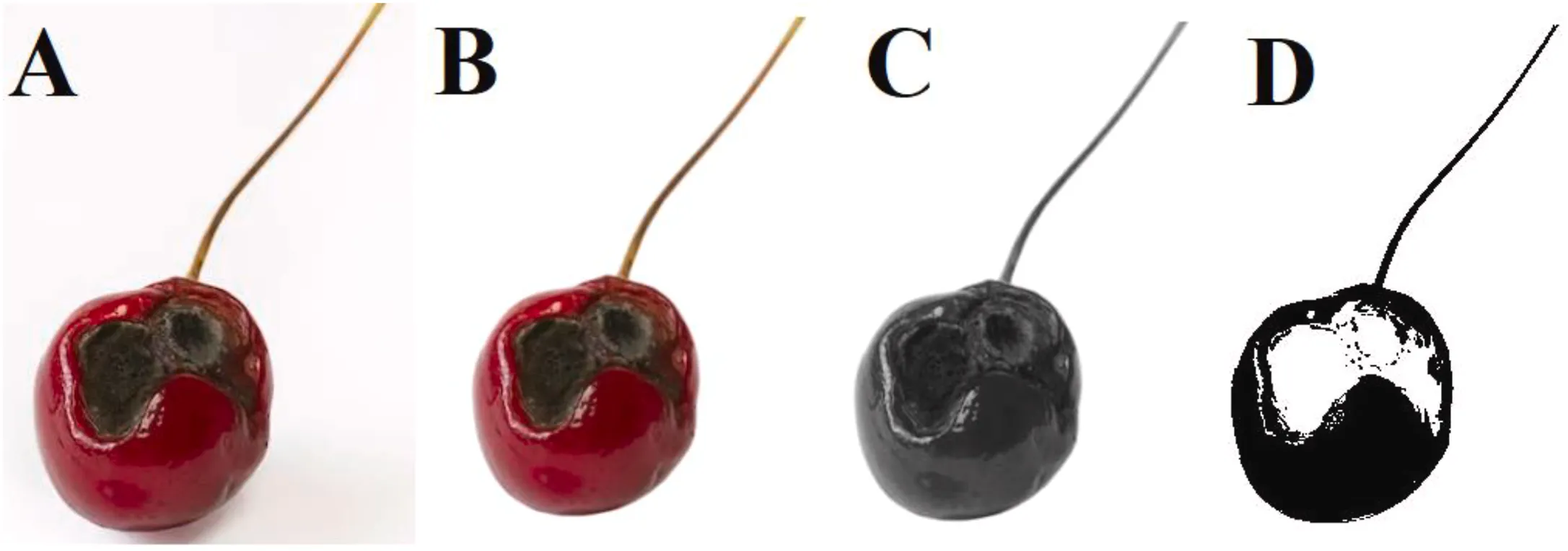

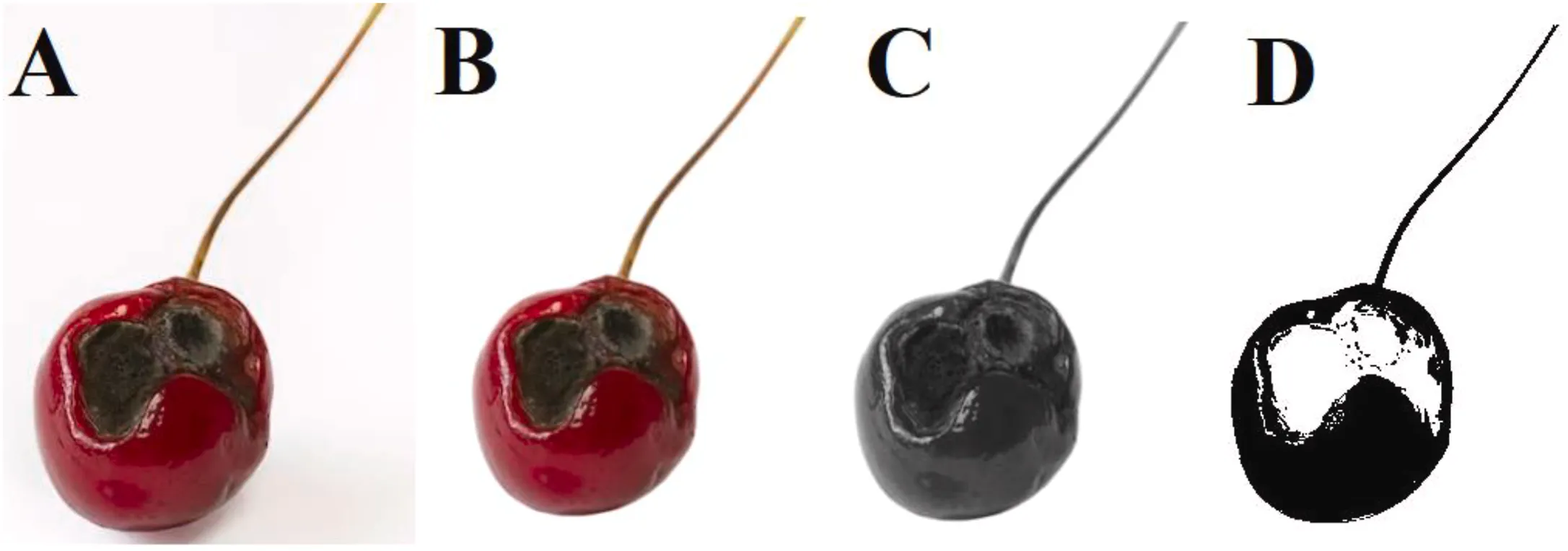

Image 1:A) RGB image, (B) Image without background, (C) Gray image, and (D) Binary image. The preprocessing for the images accomplished with using MATLAB R2019a software (Mathworks, USA). Firstly, the R, G, and B color channels were extracted separately from each image after image segmentation, Laplace transforms, and noise removal with the help of a Median filter (b). The images were then converted from RGB to Grayscale (c). After that, the grayscale image was converted to a binary image with pixel values of 0 and 1 (d) using the histogram of the image and the threshold level obtained by trial and error. This conversion made separating the healthy area from the defective area easy. Source: Yashar Shahedi et al., 2024.

Image 1:A) RGB image, (B) Image without background, (C) Gray image, and (D) Binary image. The preprocessing for the images accomplished with using MATLAB R2019a software (Mathworks, USA). Firstly, the R, G, and B color channels were extracted separately from each image after image segmentation, Laplace transforms, and noise removal with the help of a Median filter (b). The images were then converted from RGB to Grayscale (c). After that, the grayscale image was converted to a binary image with pixel values of 0 and 1 (d) using the histogram of the image and the threshold level obtained by trial and error. This conversion made separating the healthy area from the defective area easy. Source: Yashar Shahedi et al., 2024.

Research conducted at the Department of Food Science and Engineering of Zanjan University (Iran) employed visual characteristics acquired from RGB images to study alterations in surface defects, estimate physical and chemical properties, and classify the quality of sweet cherries during their storage under different storage protocols.

ANN (Artificial Neural Network) and ANFIS (Adaptive Neuro-Fuzzy Inference System) models were also employed. The results showed that the ANN and ANFIS models accurately estimated the quality grades of sweet cherries in all four algorithms with over 90% accuracy. With increasing storage time, the surface damage of sweet cherries increased.

However, coating treatment and increasing the concentration of coatings reduced the rates of this damage. The results indicated that the ANFIS and ANN models demonstrated successful predictions of physical and chemical changes occurring in sweet cherries during storage by exploiting image-based colour and texture characteristics, while showing remarkable accuracy in their modelling.

The study demonstrates that physical and chemical changes in sweet cherries can be predicted using CVS, ANFIS and ANN models. The high diagnostic capability of the algorithm allows its industrial use for diagnostic, control and classification processes.

Source: Yashar Shahedi, Mohsen Zandi, Mandana Bimakr, A computer vision system and machine learning algorithms for prediction of physicochemical changes and classification of coated sweet cherry, Heliyon, Volume 10, Issue 20, 2024, e39484, ISSN 2405-8440, https://doi.org/10.1016/j.heliyon.2024.e39484.

Images: myfruit.it; Yashar Shahedi et al 2024.

Melissa Venturi

University of Bologna (IT)

Cherry Times - All rights reserved