Sweet cherries are highly appreciated by consumers, especially for their sweet taste, vibrant color, and high antioxidant content. However, they are a highly perishable fruit with a limited shelf life of 7–10 days.

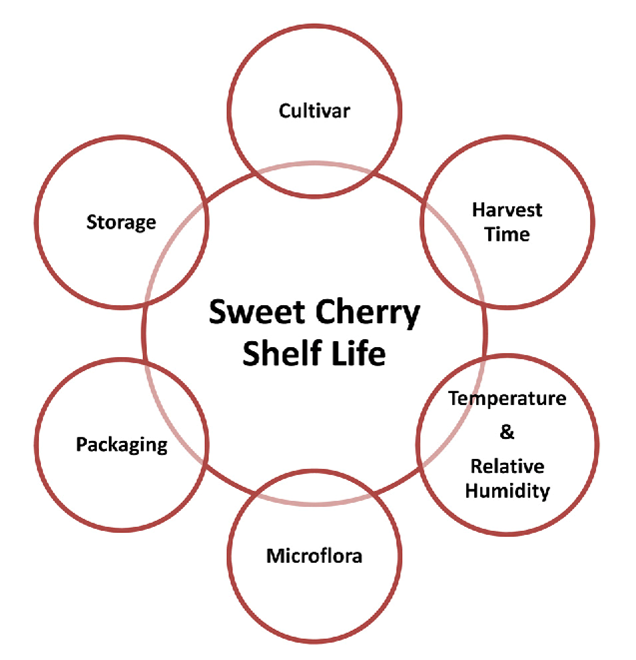

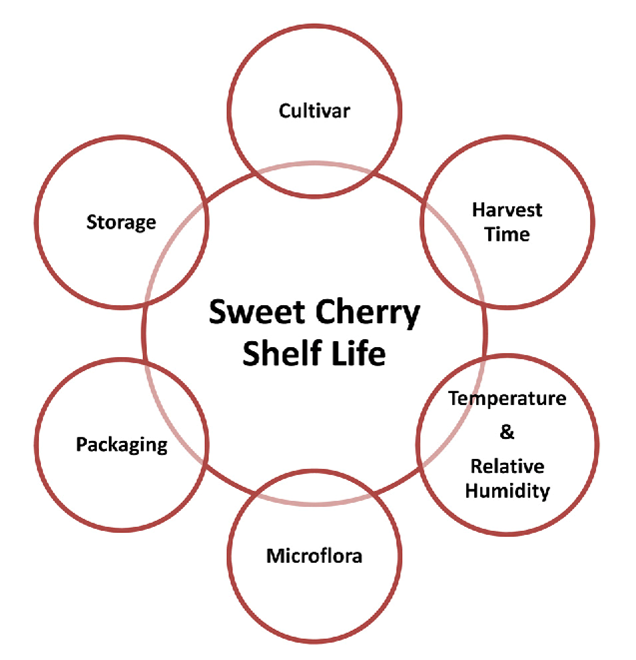

Loss of firmness, color variation, stem desiccation, and mold growth are the main issues that compromise sweet cherry quality during storage and transport. Various pre- and post-harvest factors influence the longevity and quality of the final product, and new packaging solutions are proving effective in prolonging the fruit's freshness for global markets.

Multiple pre-harvest factors affect sweet cherry quality, which can be summarized as cultivar, environmental conditions, and soil. Some examples include light intensity, temperature, inter- row management, irrigation, fertilization, rootstock, training system, and crop load, just to name a few. The cultivar used plays a fundamental role in important parameters such as productivity, fruit size, color, and sweetness.

Additionally, harvesting and the conditions under which it takes place have a significant impact on quality. The timing of harvest and handling techniques are crucial for maintaining the fruit's qualitative characteristics. Cherries must be harvested at the right maturity stage, avoiding both early harvesting, which compromises flavor and sweetness, and late harvesting, which leads to excessive softness and greater susceptibility to deterioration.

Image 1. Factors influencing the shelf life of fresh cherries.

Image 1. Factors influencing the shelf life of fresh cherries.

After harvesting, managing temperature and relative humidity is crucial to slowing down the metabolic processes that cause fruit deterioration. Rapid cooling to temperatures close to 0°C and maintaining a relative humidity of 90–95% help reduce weight loss and the risk of mold growth. Strict temperature control throughout the entire distribution chain is essential to maintaining sweet cherry quality until consumption.

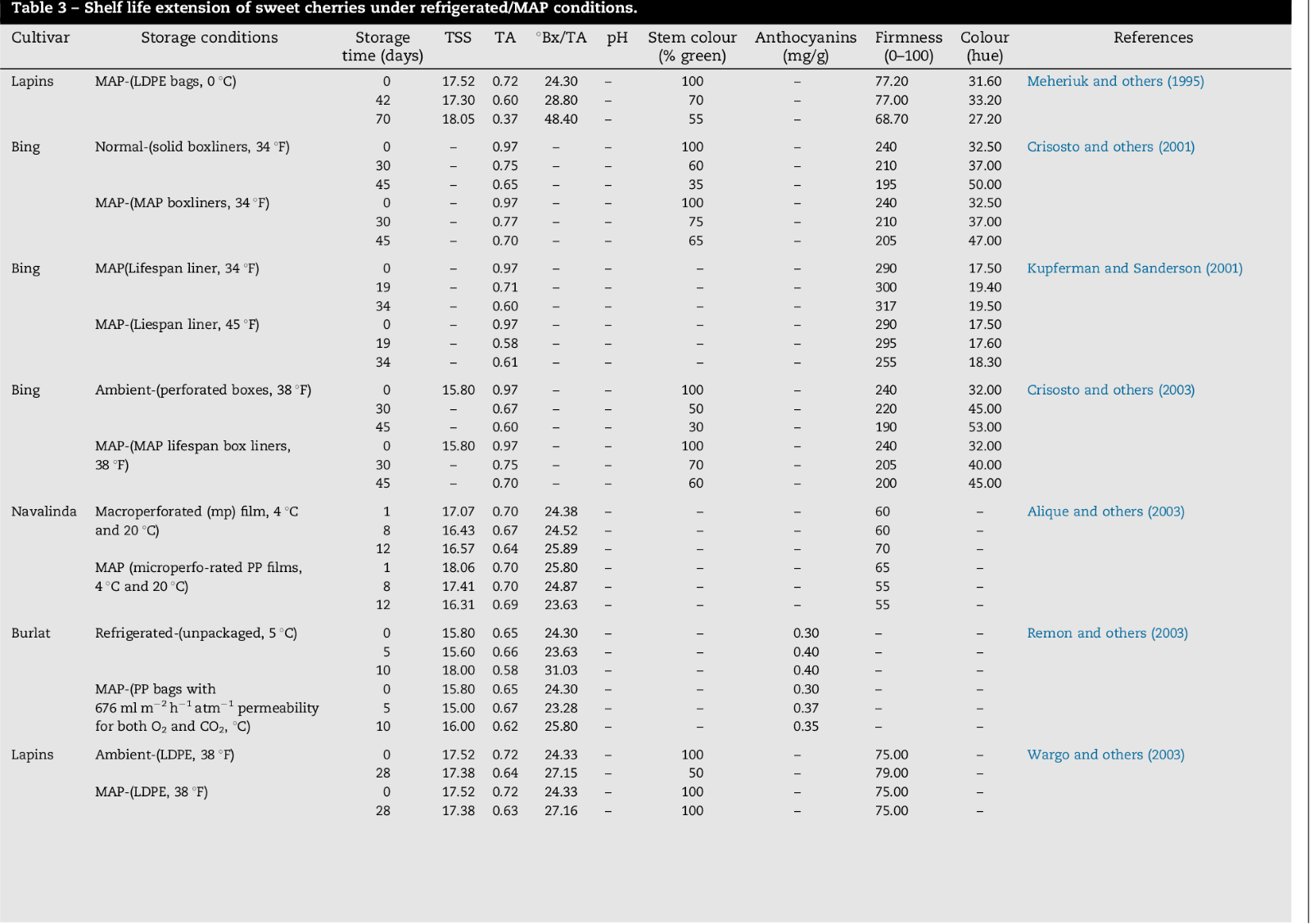

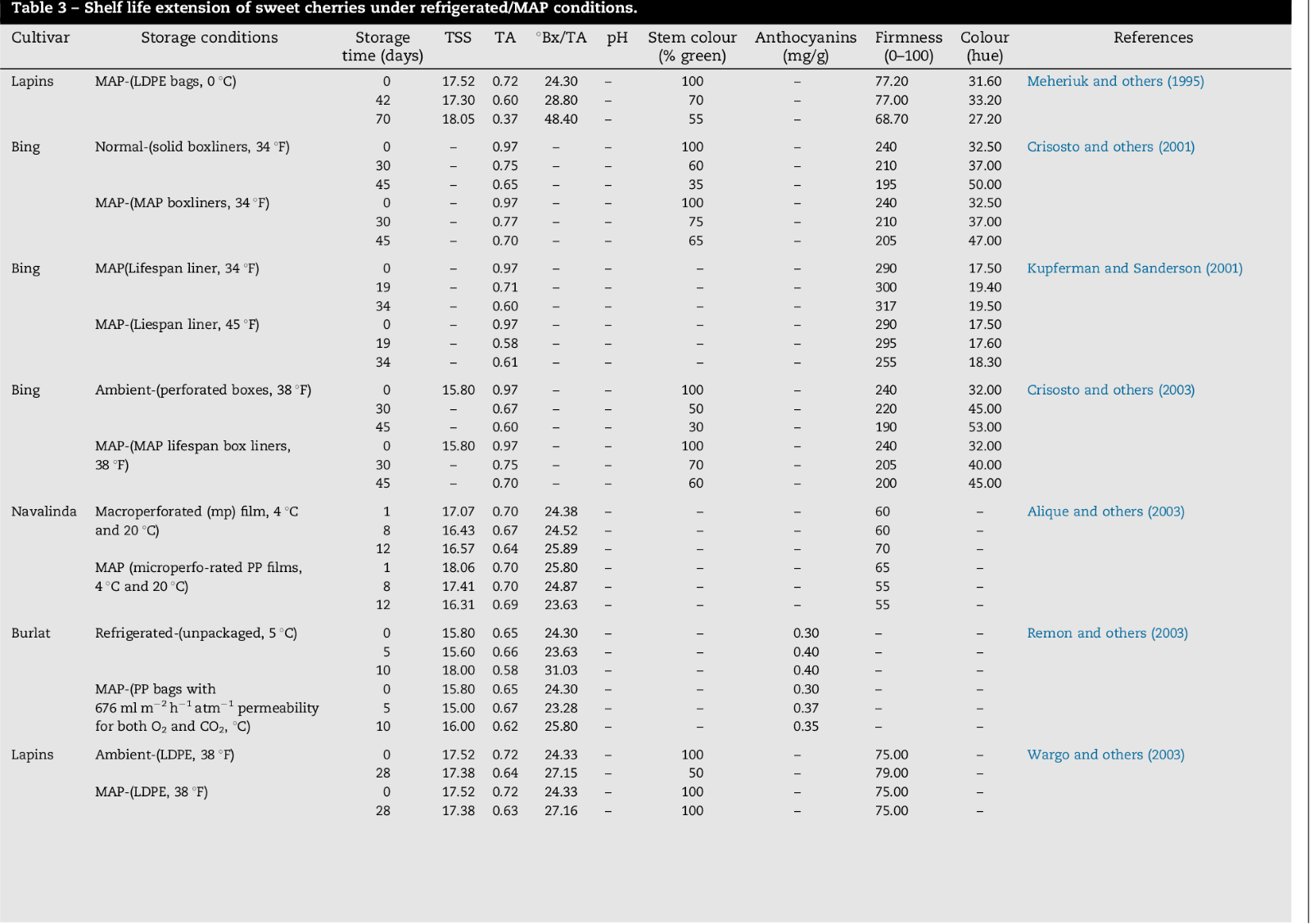

One of the most significant advancements in sweet cherry preservation is the use of modified atmosphere packaging (MAP). This system involves the use of sealed packaging that regulates oxygen (O2) and carbon dioxide (CO2) levels to slow fruit metabolism and deterioration.

Research has shown that CO2 levels between 10% and 15% and O2 levels between 3% and 10% can significantly extend the sweet cherries shelf life. Modified atmosphere conditions also help preserve the green color of the stem, a highly appreciated aesthetic characteristic among consumers.

Image 2. Extended shelf life of sweet cherries under refrigerated/MAP conditions.

Image 2. Extended shelf life of sweet cherries under refrigerated/MAP conditions.

A further advancement is the integration of MAP with active packaging, which utilizes materials capable of absorbing oxygen, emitting carbon dioxide, or releasing antimicrobial agents to counteract mold proliferation. These solutions can further improve fruit preservation and reduce losses along the supply chain.

Despite advancements in post-harvest management and packaging, strict control over all distribution chain stages is necessary to ensure that cherries reach consumers in optimal condition. Implementing integrated strategies for both pre- and, especially, post-harvest management is key to reducing waste and improving the final product's quality. With continuous attention to research and innovation, the sweet cherry industry can expand its presence in international markets by offering a fresher, higher-quality product.

Source: Wani, A. A., Singh, P., Gul, K., Wani, M. H., C Langowski, H. C. (2014). Sweet cherry (Prunus avium): Critical factors affecting the composition and shelf life. Food packaging and Shelf life, 1(1), 86-99.

https://doi.org/10.1016/j.fpsl.2014.01.005

Photo credits: Ali Abas Wani et al.; SL Fruit Service

Andrea Giovannini

University of Bologna (IT)

Cherry Times - All rights reserved