The INIA team assessed the impact of different harvest containers on the fruit quality of various cherry varieties. Cherries are particularly prone to mechanical damage due to compression, impact, abrasion, or adhesion, both on the fruits and the stems. Additionally, the use of humidifiers in collection centers is mentioned as a related topic.

To ensure the quality and condition of the fruit under prolonged storage conditions, it is necessary to implement proper management throughout the entire chain, from cultivation to final consumer presentation. Within this chain, the harvesting phase is among the most critical, as it poses a high risk of stress and damage to the fruit due to improper handling or inadequate storage conditions.

There are two main aspects to manage during harvesting: first, avoiding damage from handling during harvesting itself, which can cause bruising, splitting, or potential “pitting” in some varieties; second, reducing the respiration rate of the fruit to delay senescence. Proper management of these two factors is essential to improve postharvest shelf life, reducing phenomena such as softening, browning, and dehydration.

The use of misting systems installed in the harvest rooms to regulate temperature and humidity, as well as careful handling of the fruit using appropriate containers, can help maintain quality by avoiding damage, weight loss, and firmness loss due to dehydration.

Figure 1: Use of different types of containers for cherry harvesting: A) totem crate, B) bucket, C) cover tarp.

Figure 1: Use of different types of containers for cherry harvesting: A) totem crate, B) bucket, C) cover tarp.

Assessment of container use

Cherries are particularly sensitive to mechanical damage from compression, impact, abrasion, or adhesion, both on the fruit and the stem, potentially affecting even the internal layers of the mesocarp (flesh), leading to internal cellular collapse. One of the main concerns for producers is understanding to what extent damage caused during harvesting is attributable to the container used and how it can potentially be reduced.

Today, the choice of harvesting containers is based on efficiency in terms of speed and yield, but also on practicality for transport and reception at export facilities.

For this reason, the 10 kg "totem" crate is the most commonly used container, as it is the only format that can be transported inside larger bins. However, regardless of this and the fact that each orchard may adopt a different type of container (small bucket, basket, or crates of various sizes), it is observed that the most experienced pickers tend to prefer their own containers for convenience.

It has been known for years that practices such as overfilling containers can cause damage in varieties particularly sensitive to bruising. The use of soft padding inside containers, as well as care in limiting impacts, compressions, and excessive handling during fruit accumulation and transfer, are useful practices to reduce damage. In this context, it is interesting to assess whether fruit handling during harvest affects the onset of damage, disorders, or quality parameters during postharvest.

Types of containers assessed

Based on this hypothesis, the effect of using three different types of harvest containers was analyzed on various quality aspects of the fruit, both at harvest and after storage, across four varieties: Santina, Lapins, Sweet Heart, and Regina.

“Totem” crate: These are stackable rigid plastic crates (hence the name “Totem”), equipped with slits that allow ventilation. Their capacity ranges from 9 to 12 kg of fruit.

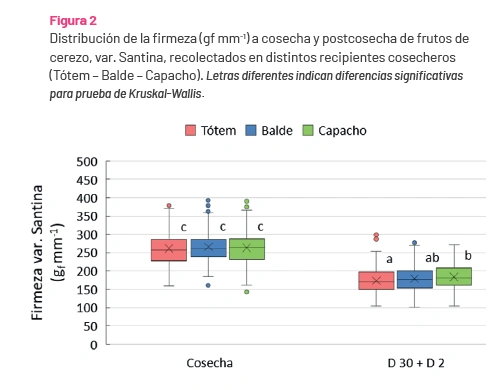

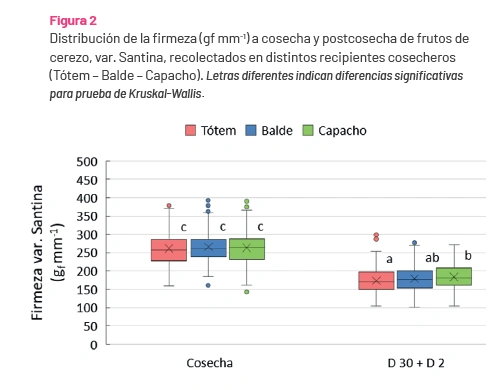

Figure 2. Distribution of firmness (gf mm⁻¹) at harvest and postharvest of cherry fruits, cv. Santina, harvested using different containers (Totem – Bucket – Chest). Different letters indicate significant differences according to the Kruskal-Wallis test.

Figure 2. Distribution of firmness (gf mm⁻¹) at harvest and postharvest of cherry fruits, cv. Santina, harvested using different containers (Totem – Bucket – Chest). Different letters indicate significant differences according to the Kruskal-Wallis test.

Pickers carry them using a harness, placing the fruit directly inside (Figure 1.A). Their use is widespread as they represent the standard format for introducing fruit into sorting and packing processes. Moreover, being wider than they are deep, it is believed that the fruit undergoes less compression and bruising. However, due to their size and weight, they are less convenient to use with harvest ladders.

Harvest buckets: These are plastic containers with a conical or cylindrical shape, padded at the bottom with plastic or foam, and designed for use with a harness. They are used to collect the fruit, which is then transferred into larger containers (such as the totem crate).

They have a capacity ranging from 3 to 6 kg. They allow for lighter transport and less impact on tree branching. However, due to the transfer and compression of fruit at the bottom, they are believed to be more prone to injuries and bruising (Figure 1.B).

Capachos: These are sacks with a cylindrical plastic base and a wide top opening. The interior is lined with foam and then covered with synthetic leather and rubberized fabric. Unlike buckets, the transfer into the totem crate occurs by sliding the contents out through the canvas bottom. Their capacity ranges from 4 to 5 kg (Figure 1.C).

Operational efficiency and firmness

The effect of using different types of containers on the efficiency or yield of harvesting by workers has been another recurring question among producers. However, based on tests carried out to evaluate these variables, no significant differences were found between the different containers. Clearly, containers with smaller capacity fill up faster, but it is the phase of transporting the harvested fruit to the storage and registration base that most affects the efficiency of the pickers.

For this reason, it is necessary to carefully plan the layout of the storage bases and/or provide a team of workers dedicated exclusively to collecting the harvested fruit.

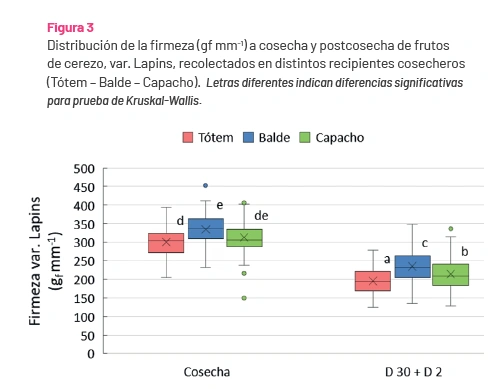

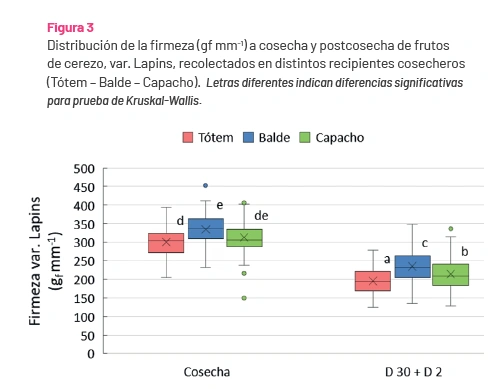

Figure 3. Distribution of firmness (gf mm⁻¹) at harvest and postharvest of cherry fruits, cv. Lapins, harvested using different container types (Totem – Bucket – Chest). Different letters indicate significant differences according to the Kruskal-Wallis test.

Figure 3. Distribution of firmness (gf mm⁻¹) at harvest and postharvest of cherry fruits, cv. Lapins, harvested using different container types (Totem – Bucket – Chest). Different letters indicate significant differences according to the Kruskal-Wallis test.

Fruit firmness is considered a highly appreciated quality attribute by consumers, in addition to being a determining factor for resistance to mechanical damage, handling efficiency, and response to thermal changes. However, firmness can be compromised as early as the harvesting stage by impacts or compression in the container, affecting various quality parameters and the shelf-life during commercialization.

For example, in the Santina variety, the use of different containers did not affect the firmness of freshly harvested fruit (Figure 2). However, after storage at 0 °C and a short shelf period of two days at 20 °C, firmness decreased significantly by between 30% and 35% compared to harvest, showing that fruits harvested with the capacho had lower firmness losses than those harvested with the totem container.

These results are also confirmed by data for the Lapins variety. During harvest, statistically significant differences in fruit firmness were observed among the different containers, particularly between those harvested with the totem and the bucket (Figure 3). These differences were also maintained postharvest, with firmness losses between 30% and 35%. It can be concluded that fruits harvested using bucket and capacho containers retained greater firmness than those harvested using the totem crate.

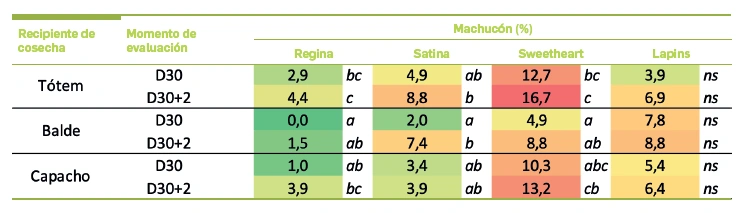

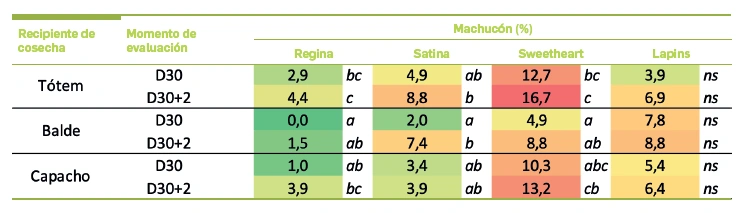

Table 1. Evolution of the percentage of bruising in postharvest cherry fruits harvested using different container types (Totem-Bucket-Capacho). Different letters in each column for the various container treatments indicate significant differences according to the Kruskal-Wallis test, p<0.05. Colors indicate damage severity: green = minor damage; yellow = moderate damage; red = severe damage.

Table 1. Evolution of the percentage of bruising in postharvest cherry fruits harvested using different container types (Totem-Bucket-Capacho). Different letters in each column for the various container treatments indicate significant differences according to the Kruskal-Wallis test, p<0.05. Colors indicate damage severity: green = minor damage; yellow = moderate damage; red = severe damage.

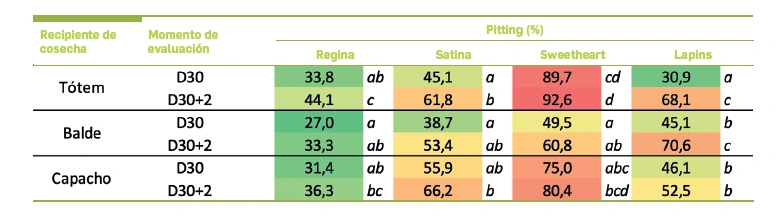

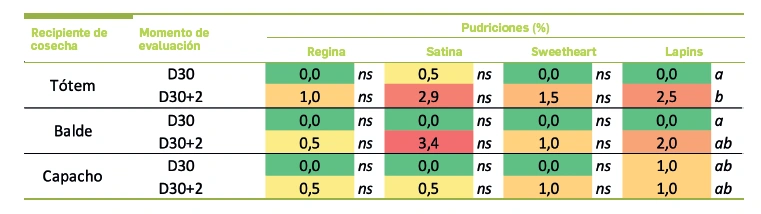

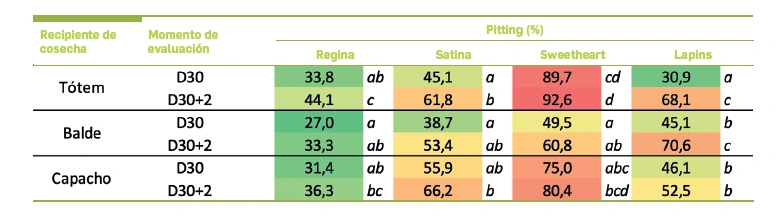

Table 2. Evolution of the percentage of pitting in postharvest cherry fruits harvested using different container types (Totem - Bucket - Capacho). Different letters between treatments indicate significant differences according to the Kruskal-Wallis test. Colors indicate damage severity: green = minor damage; yellow = moderate damage; red = severe damage.

Table 2. Evolution of the percentage of pitting in postharvest cherry fruits harvested using different container types (Totem - Bucket - Capacho). Different letters between treatments indicate significant differences according to the Kruskal-Wallis test. Colors indicate damage severity: green = minor damage; yellow = moderate damage; red = severe damage.

Bruising: the main cause of deterioration

Mechanical damage, particularly bruising, is the most common form of deterioration in cherry fruits during harvesting, transport, and handling. This type of damage is one of the main causes of quality loss and commercial devaluation of the fruits and does not manifest immediately after harvest but tends to appear later, after cold storage, worsening over time. Bruising can be caused by various factors, such as compression of the fruit, impact against hard surfaces or other fruit, excessive force during harvesting, or transfer between containers.

The results reported in Table 1 show significant differences in the incidence of bruising depending on the variety and the type of container used for harvesting. There is a marked variability among the four studied varieties (Santina, Lapins, Sweet Heart, and Regina). The Sweet Heart variety appears to be the most susceptible to mechanical damage, while Regina shows the least susceptibility.

In general, the totem-type container tends to be associated with higher damage rates, particularly during the shelf-life evaluation (D30+D2) of the Sweet Heart variety. It is important to note that regardless of the container used, there is a general increase in the number of bruised fruits between the evaluation carried out a few hours after leaving cold storage and the one conducted after two days on the shelf, indicating a progression of mechanical damage in postharvest.

This phenomenon is particularly evident in the Santina variety, where the use of the bucket significantly affects the incidence of bruising during the shelf-life phase. The results suggest that, although container choice influences postharvest quality, its effectiveness varies depending on the variety. Therefore, producers should adapt harvesting practices based on both the type of container and the specific characteristics of each cultivar.

Pitting: a physiological disorder

Pitting is characterized by the appearance of small irregular depressions (4–8 mm) on the surface of the fruit, caused by cellular collapse just beneath the skin. Although it can be linked to various agronomic and environmental factors, it is generally interpreted as the consequence of impact or compression damage not visible during harvesting or handling but which manifests during cold storage. Susceptibility to pitting also depends on the variety, ripeness stage, and fruit firmness. Other influencing factors include temperature conditions, postharvest dehydration, and the material or design of the containers used.

As observed with bruising, results indicate that fruit harvested in the totem crate shows a higher incidence of pitting in most varieties, particularly in Sweet Heart. For the Santina variety, no significant differences were found between containers, although the capacho showed a lower progression of damage during postharvest. It should be noted, however, that all studied varieties showed a general increase in pitting during the shelf-life phase (Table 2). Regina was the variety with the lowest incidence of this type of damage.

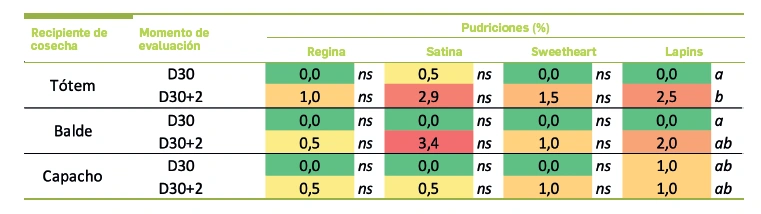

Table 3. Evolution of the percentage of decay in postharvest cherry fruits harvested using different container types (Totem - Bucket - Capacho). Different letters between treatments indicate significant differences according to the Kruskal-Wallis test. Colors indicate damage severity: green = minor damage; yellow = moderate damage; red = severe damage.

Table 3. Evolution of the percentage of decay in postharvest cherry fruits harvested using different container types (Totem - Bucket - Capacho). Different letters between treatments indicate significant differences according to the Kruskal-Wallis test. Colors indicate damage severity: green = minor damage; yellow = moderate damage; red = severe damage.

The development of decay

Although generally well-controlled thanks to the use of broad-spectrum fungicides, the problem of decay can still occur during postharvest, as cherries are highly susceptible to fungal infections. The most common pathogens at this stage include Botrytis, Penicillium, Alternaria, and Cladosporium.

These infections compromise fruit quality, reduce shelf life, and cause significant commercial losses. Damaged fruits are particularly vulnerable, as lesions provide a convenient entry point for pathogens. For this reason, preventing physical damage during harvest and implementing proper postharvest management are crucial to minimizing losses due to fungal decay.

Table 3 shows that the Santina variety is the most sensitive to this issue, recording the highest percentages of decayed fruit, especially when using buckets or totem crates. After 32 days (D30+2), 3.4% of fruits were compromised. Regarding containers, the totem shows the highest incidence of decay across all analyzed varieties, with consistently higher values in the D30+2 phase. The highest percentages recorded with this container are: 1.0% in Regina, 2.9% in Santina, 1.5% in Sweet Heart, and 2.5% in Lapins. Although these are generally low values, the totem container clearly tends to favor the development of decay more than the others.

The totem shows the worst results

The combined analysis of pitting, decay, firmness, and bruising across four cherry varieties (Sweet Heart, Santina, Regina, and Lapins) highlights that the choice of harvest container has a significant impact on postharvest fruit quality. The bucket stands out as the most favorable container, reducing damage and maintaining better firmness across all varieties. In contrast, the totem crate shows the worst results, especially concerning bruising and firmness loss. The capacho falls somewhere in between.

Susceptibility to damage also varies by variety: Sweet Heart is the most sensitive and requires greater care, while Regina proves more resistant, especially when harvested with the bucket. Santina and Lapins show intermediate sensitivity, with Lapins displaying less variability in bruising but more firmness loss depending on the container used.

All of this highlights the importance of adapting harvest and postharvest practices to the specific characteristics of each variety, favoring the use of the bucket to optimize cherry quality and shelf-life.

Source text and images: mundoagro.cl

Cherry Times - All rights reserved