The consultant Jessica Rodríguez, agronomist engineer, M.Sc., partner at Trío Kimún, recounts her experience in the inspection of cherry boxes upon arrival in China during the 2024/25 season, during which she observed a significant incidence of rots. Her analysis considers three contexts: what occurred in Chile, what she was able to personally observe during the reception phase in China, and the measures required to overcome the issues identified. Her conclusions were presented at the IX Postharvest Conference 2025, held at the Pontificia Universidad Católica.

Image 1. Jessica Rodríguez

Image 1. Jessica Rodríguez

The percentage of fruit with rot is increasing

During the initial stages of processing cherries intended for fresh consumption, large volumes of water in continuous recirculation are used throughout daily shifts. This represents a risk factor for the possible presence of microorganisms that can compromise both human health and product quality.

The most commonly used sanitizer is sodium or calcium hypochlorite (chlorine), although halogenated products (stabilized chlorines) are also used. For environmental reasons, the use of peracetic acid has also become more widespread in recent years.

The industry faces a difficult dilemma

Chlorine used for water sanitization in food processing is contested under European environmental regulations, prompting the industry to introduce automated application systems and to reduce dosages through pH regulation.

Lower chlorine concentrations also reduce odor-related issues in packing facilities and make compliance with national regulations on industrial wastewater treatment slightly easier.

However, the expert stresses that it is necessary to be aware that lower concentrations involve a smaller margin for error in ensuring pathogen control, especially fungi. Today the industry operates in a very different scenario compared to ten years ago: higher fruit volumes mean larger processing lines, longer shifts, and harvests that include a greater amount of leaves.

In this context, a significant amount of organic matter accumulates on the lines, placing the industry at a difficult crossroads. Because volume pressure leaves little time for cleaning operations, it is not uncommon to find dirty tanks already in the morning, as well as corners where fruit or residues become trapped (image 2).

Image 2. Moisture clearly visible at the bottom of the box. Upon opening the box, brown rot was detected.

Image 2. Moisture clearly visible at the bottom of the box. Upon opening the box, brown rot was detected.

Rots visible upon arrival

2. Moisture clearly visible at the bottom of the box.

3. Upon opening the box, brown rot was observed.

The spring of 2024 recorded high morning humidity, combined with a high production load in orchards and a large presence of clustered fruit. As a result, a non-negligible proportion of floral residues remained trapped and hidden within these clusters.

According to Jessica Rodríguez’s discussions with specialist plant pathologists, this led to the presence of inoculum close to harvest, invisible to the naked eye and undetected even by electronic control systems. The crop protection products applied likely failed to reach them effectively, allowing them to make it into packed boxes.

Defects generated uncertainty

For many years, buyers have adopted a rapid methodology for box inspection. First, they lift the lid and check that at least the top layer matches the requested product.

Second, they examine the bottom of the box and check that it shows no stains, considering this an indicator of a low probability of internal rot. In general, no issues were detected in previous seasons.

In the last campaign, however, there were boxes with wet corrugated liners, with moisture clearly visible at the bottom. Upon opening the corrugated liners, brown rot was detected.

The responsibility does not lie with the packinghouse, Rodríguez clarifies, since the rotten fruit failed to contaminate the surrounding environment, from which it can be inferred that the application of sanitizers and fungicides was effective in containing the damage.

More intensive inspections and new challenges

“But from the standpoint of economic outcome, it makes no difference whether there is one or ten rotten cherries,” the specialist notes.

Although the issue was not widespread across the entire industry, it had a significant impact. During the last season, while in China, nearly 300 boxes were surveyed, and 8% showed the described symptom.

This percentage, although low, was higher than in previous seasons. It had a major effect, as it generated insecurity among buyers, who doubled and tripled the intensity of inspections across all operators.

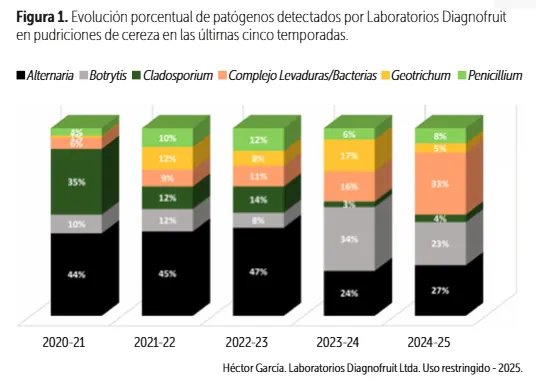

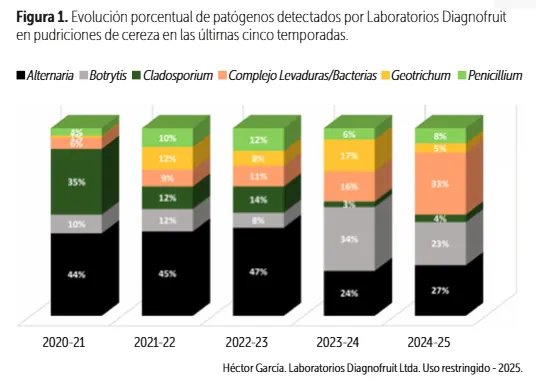

Figure 1. Percentage evolution of pathogens detected by Diagnofruit Laboratories in cherry rots over the last five seasons.

Figure 1. Percentage evolution of pathogens detected by Diagnofruit Laboratories in cherry rots over the last five seasons.

Obviously, this approach also revealed other issues that had previously gone unnoticed. An additional cause for concern is the detection of yeasts. Although the damage is not widespread, their contribution to rot has increased season after season and is present in arrivals from more than one company.

Strategies and products to reassess

Boxes like the one shown in photo 5 cannot be marketed. Figure 1, referring to samples received by the Diagnofruit laboratory, shows an upward trend in the detection of the bacteria-yeast complex.

This highlights the need for attention in packinghouses, addressing not only fungi but also other pathogens. Fungicides do not contribute to yeast control, while sanitizers may help, the consultant states.

In summary, according to Rodríguez’s findings at destination:

- Part of the industry may have partially neglected the elimination of other aesthetic fruit defects during processing, which, combined with the presence of rot, resulted in a higher-than-average number of problematic boxes.

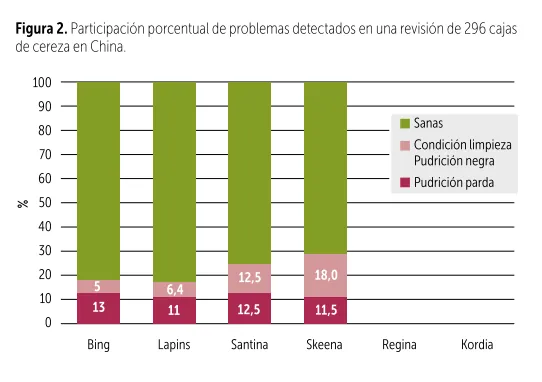

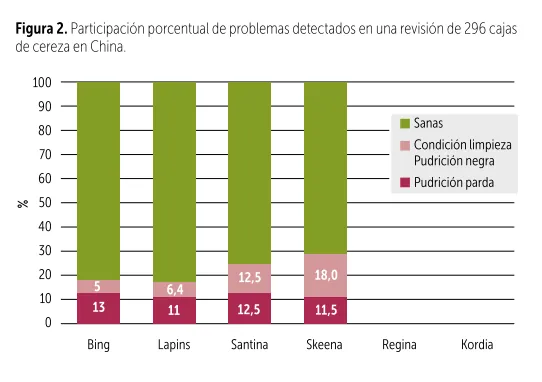

Deficiencies in temperature management were also observed, with fruit that may not have undergone pre-cooling or was insufficiently cooled. All this led to an increase in inspections. Figure 2 summarizes the findings from 296 boxes examined in China.

The Regina and Kordia varieties showed no significant issues, while other varieties displayed a similar distribution of defects.

Figure 2. Percentage incidence of issues detected during the inspection of 296 cherry boxes in China.

Figure 2. Percentage incidence of issues detected during the inspection of 296 cherry boxes in China.

Postharvest management and control

Regarding fungicides, fludioxonil is currently applied in the final tank. On the one hand, a low sanitizer dose is used, a practice required for food safety certification; on the other hand, this tank is among those replaced less frequently, as cost considerations lead to longer use. For both reasons, this represents a critical point.

Immersion application in the final stage can sometimes create issues. In China, dissatisfaction currently arises when fruit becomes stained due to application. The industry would greatly benefit from the development of alternatives that reduce limitations stemming from maximum residue limits.

In a 2019 study involving exporters, crop protection companies, and Diagnofruit, exporters were asked to process and store fruit from growers with the highest incidence of black rot (Alternaria) and gray rot (Botrytis).

Postharvest fungicide applications were evaluated, and a significant reduction in rot was observed after 30 days of storage at 0°C. However, given the high initial incidence of pathogens, the results did not eliminate the problem.

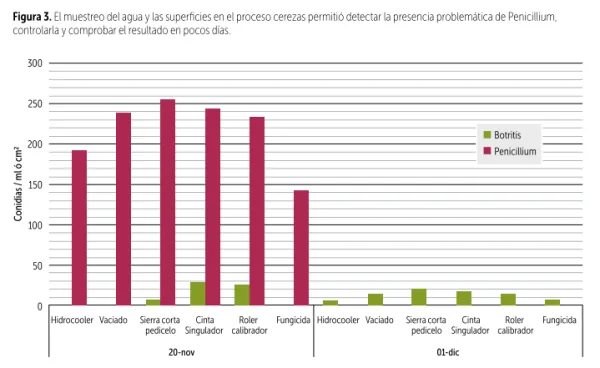

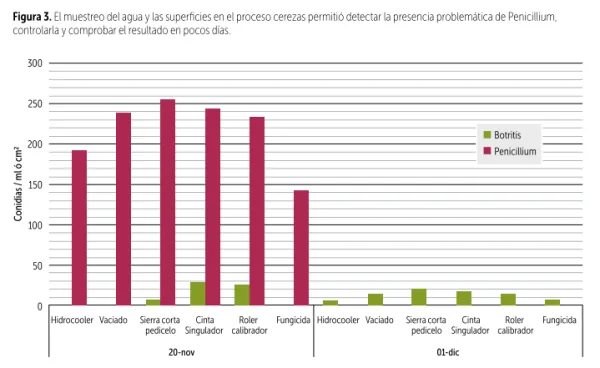

Figure 3. Sampling of water and surfaces in cherry processing made it possible to detect problematic Penicillium presence, control it, and verify outcomes within a few days.

Figure 3. Sampling of water and surfaces in cherry processing made it possible to detect problematic Penicillium presence, control it, and verify outcomes within a few days.

Harvest, sanitization, and genetics

Among postharvest fungicide alternatives, fludioxonil provides good control not only of the two aforementioned fungi but also of Penicillium, Monilia, and Rhizopus, while it does not control Geotrichum. The fungicide pyrimethanil follows in effectiveness but controls neither Geotrichum nor Rhizopus.

Tebuconazole, contested in Europe, is the only product capable of controlling Geotrichum and is used by the industry as a complement to fludioxonil. Fenhexamide provides excellent control exclusively of Botrytis, which is why it has been allocated to field use.

Photo 6 shows the cleaning of the emptying tank after a day’s work. A large quantity of organic matter residues is evident. If this material is left in the tank, it becomes a growth medium not only for fungi but also for yeasts.

In such an environment, a yeast can multiply thousands of times in a short period. Today, the industry must clean and sanitize using treatments and procedures suited to preventing postharvest rot. Sanitizers must be applied at the required concentrations.

Tools and future perspectives

Figure 4. Yeasts detected upon cherry arrival in China.

Figure 4. Yeasts detected upon cherry arrival in China.

For both chlorine and peracetic acid, it is necessary to use appropriate verification tools: test strips, a photometer (the best option), or titrations. The goal is to accurately determine the actual amount of sanitizer present.

It should also be considered that the best tool is having fruit resistant to rot development, a trait strongly associated with harvest color. Last year, one of the main industry complaints was that the Santina variety arrived very dark.

If harvest moves away from overly dark colors, focusing instead on mahogany tones, pathogens—whether fungi, bacteria, or yeasts—will undoubtedly encounter a more resistant entry barrier, also contributing to better storage performance.

Figure 5. A box in these conditions cannot be marketed.

Figure 5. A box in these conditions cannot be marketed.

Thanks to the development of qPCR techniques, it is possible to monitor pathogens from the orchard through to the packing lines. This makes it possible to analyze samples at different phenological stages before harvest and also along processing lines.

Results are obtained quickly, within two to three days, allowing timely implementation of control measures, cleaning, and sanitization as required.

An example is shown in figure 3, where, based on analysis results, Penicillium contamination was controlled and treatment effectiveness verified within a few days.

Figure 6. Organic matter residues removed from the emptying tank after a day of operation.

Figure 6. Organic matter residues removed from the emptying tank after a day of operation.

As for yeasts, it should be noted that they have always been present, but for reasons not yet fully understood, their relative contribution to rot has increased. Jessica Rodríguez raises a question many are asking: why, despite the availability of sanitizers, are major fungal problems not observed, while yeast-related issues are emerging?

“In some way, we are altering microbial populations,” she hypothesizes.

“There is a need for knowledge input on control methods, on the efficiency of different products, required doses, and the systems we use for cleaning and sanitizing lines,” the expert concludes.

Jessica Rodriguez and Redagrícola Team

Cover photo: Redagrícola

Cherry Times - All rights reserved