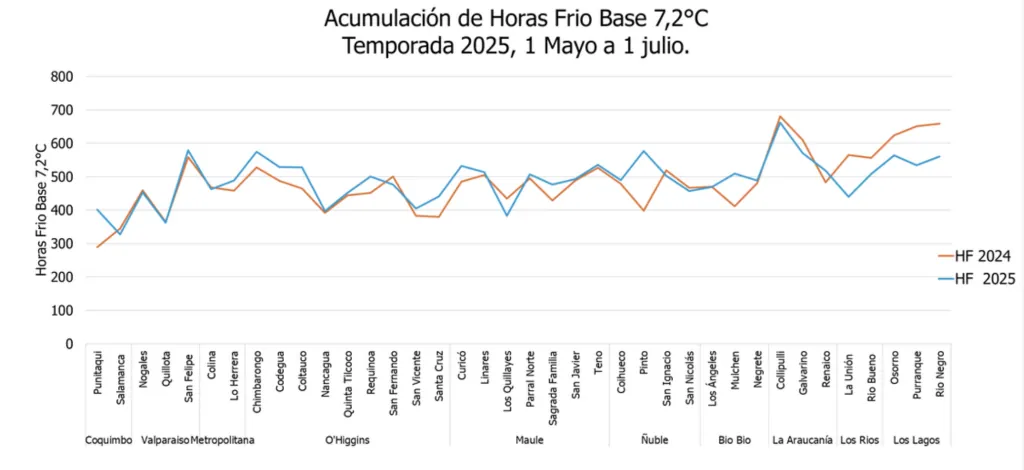

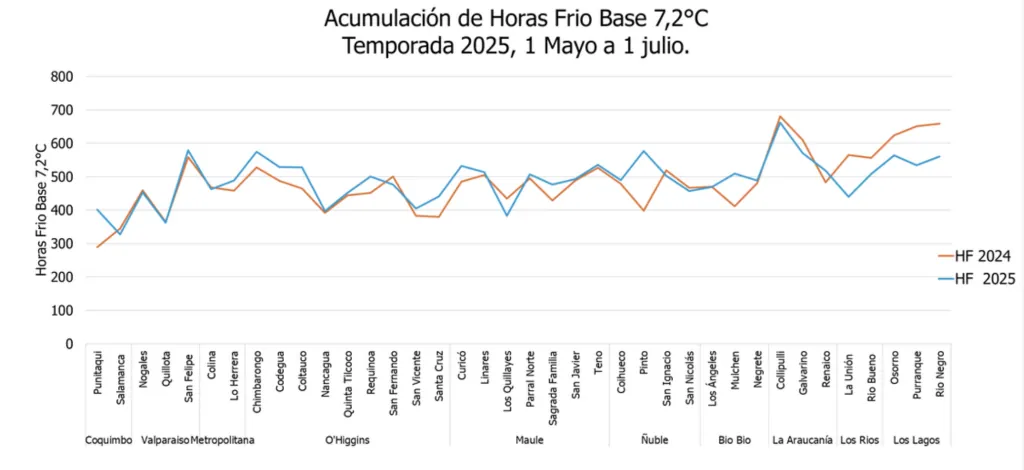

Cherry trees generally depend heavily on chill accumulation to initiate uniform bud break. In recent seasons, it has been difficult to meet chill requirements due to increasingly mild and lower-quality winters.

In this context, dormancy breakers become an important tool for managing vegetative regrowth at the end of winter dormancy.

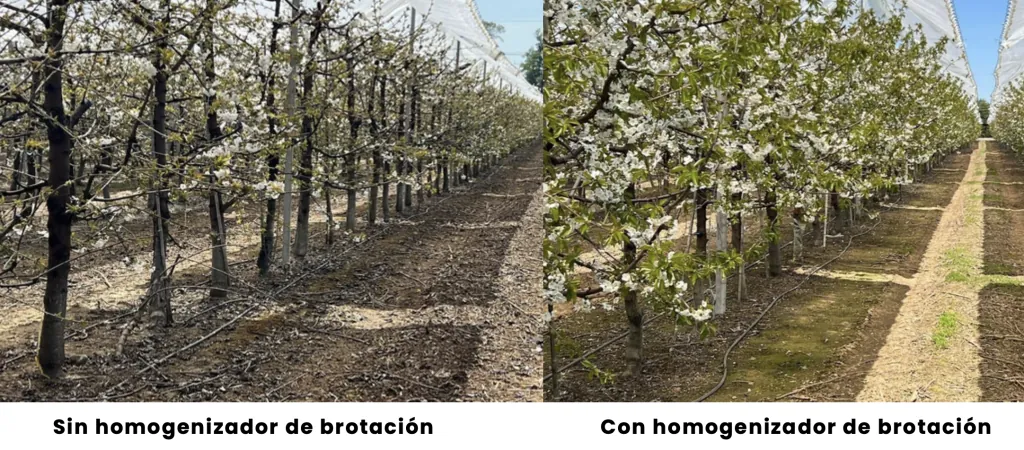

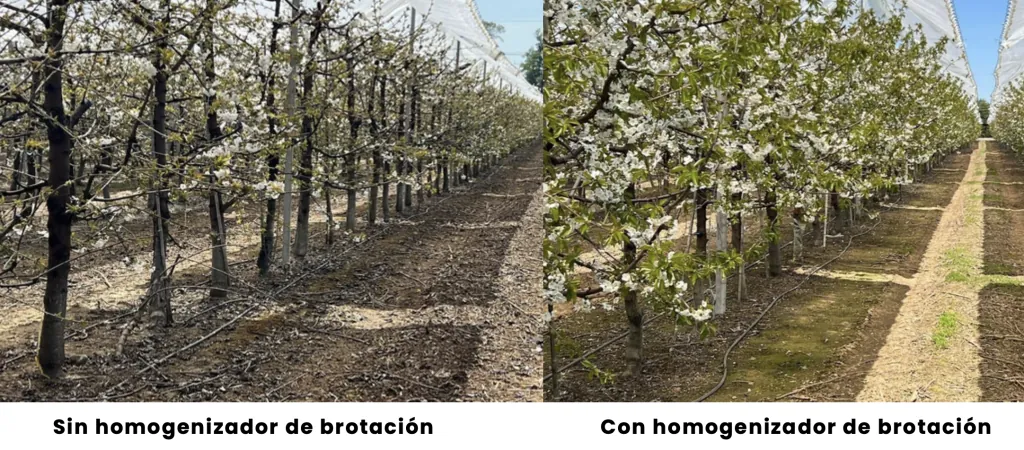

The application of dormancy breakers promotes better vegetative regrowth in orchards: their main function is to anticipate and standardize bud break, allowing tissue opening even when chill hour requirements specific to each variety have not been fully met.

In seasons with higher chill accumulation (base 7.2°C), earlier applications are advisable; conversely, in seasons with lower chill accumulation, treatments – especially hydrogen cyanamide – should be delayed to minimize dormancy disruption and allow chill accumulation until July 30.

Harvest Timing and Management

The application of dormancy breakers can bring forward harvest time or enable strategies to stagger harvest dates. Applying a breaker is essential for achieving a concentrated and uniform phenology, which allows for more efficient phytosanitary planning and higher fruit quality.

A lack of chilling and degree-day accumulation affects flower quality due to lower pollen vitality and incomplete ovary formation—factors directly linked to fruit quality.

It’s important to consider that early bud break increases the risk of cold damage, as tissues may be more susceptible during potential late frosts.

In the case of repeated frost events around or after the application, treatments should be postponed, and frost protection systems should be ready to activate immediately.

Dosage and Application Timing

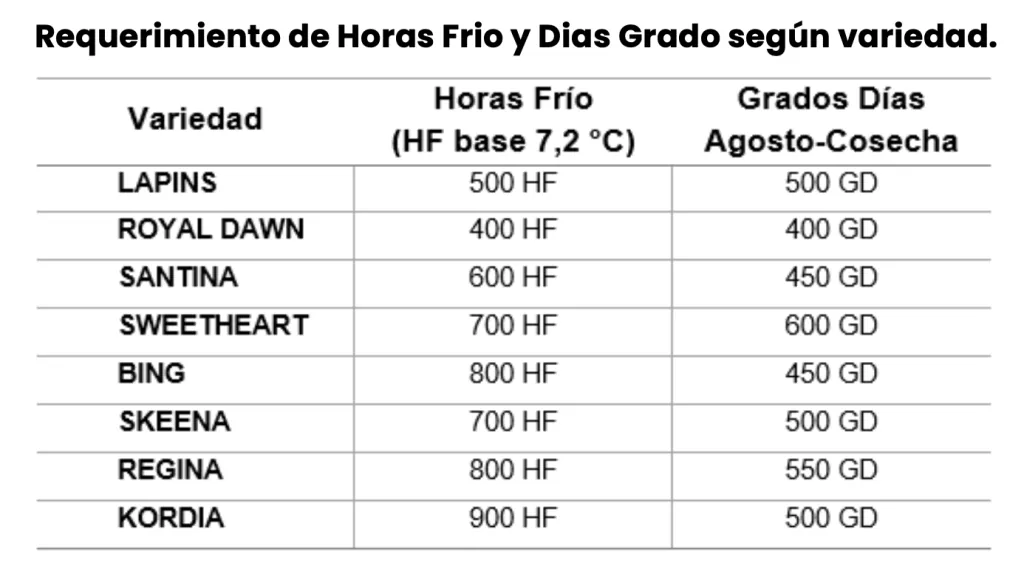

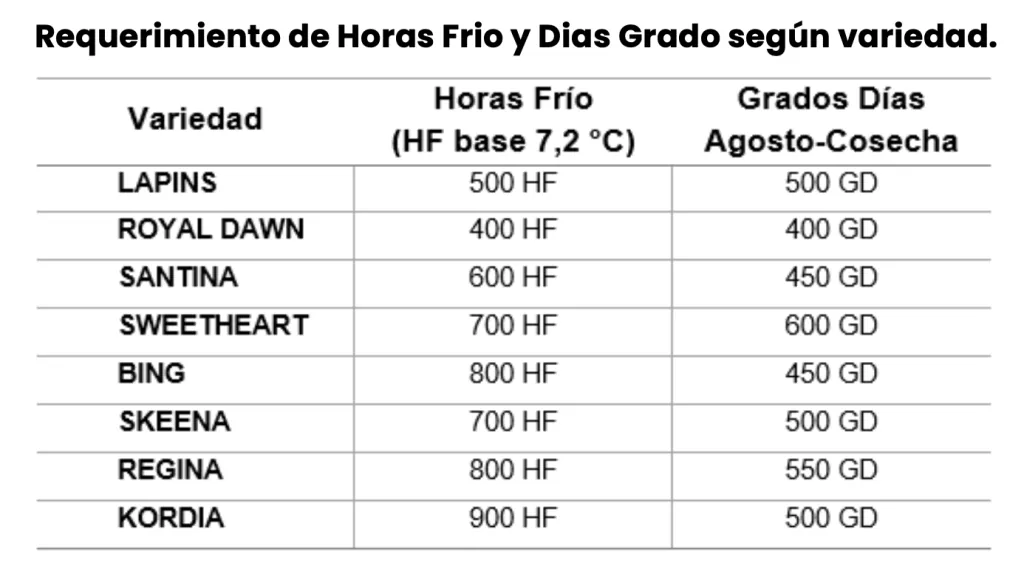

Dosages and application dates of hydrogen cyanamide vary by variety and geographical area. However, the minimum application date should coincide with reaching at least 70% of the chill hour requirement (base 7.2°C) for the specific variety.

The application of dormancy breakers becomes even more relevant in winters with low chill accumulation, as milder winters reduce reserve build-up and the quality of flower buds, leading to lower pollen and ovule viability and reduced fruit set.

Hydrogen Cyanamide

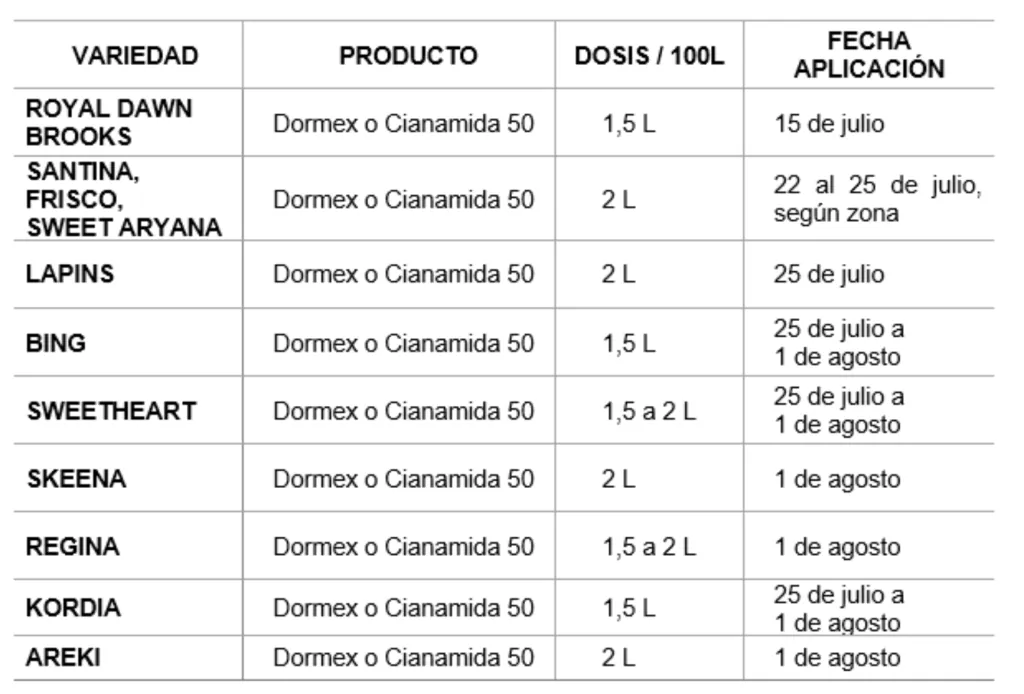

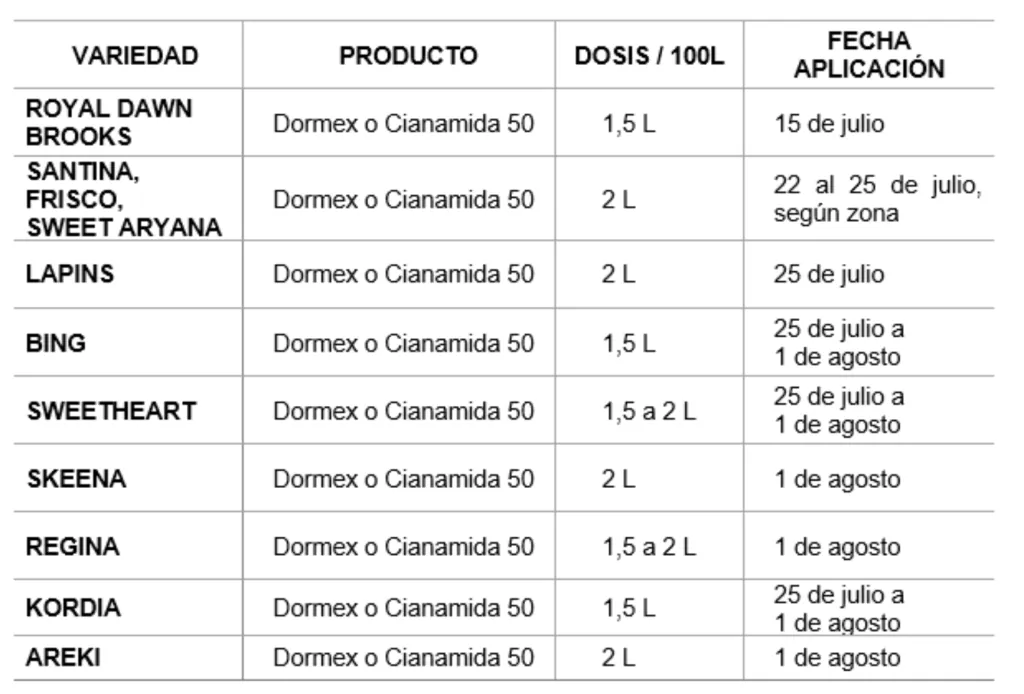

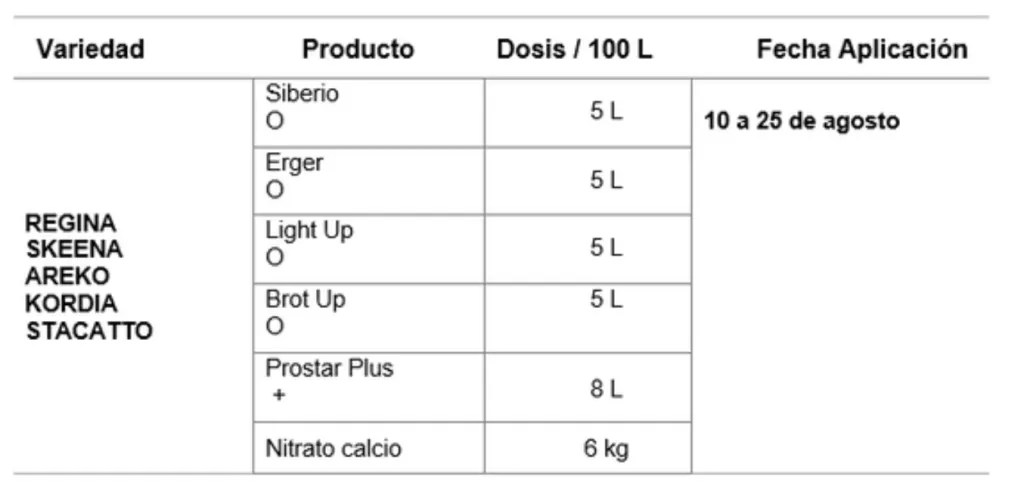

Hydrogen cyanamide usage programs and other dormancy breakers vary by variety.

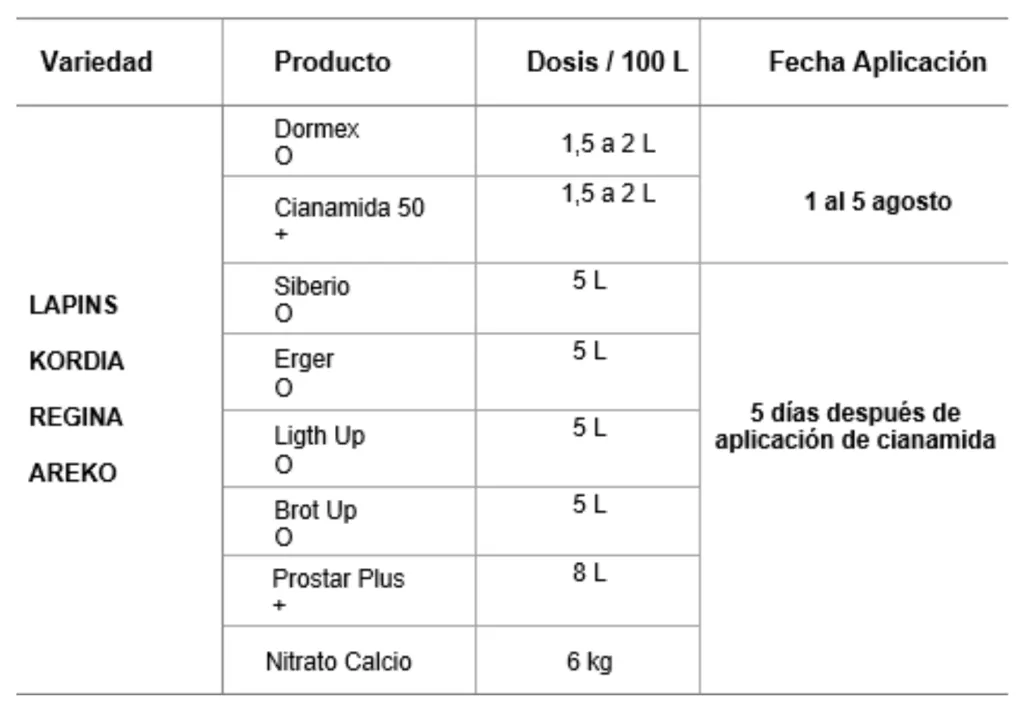

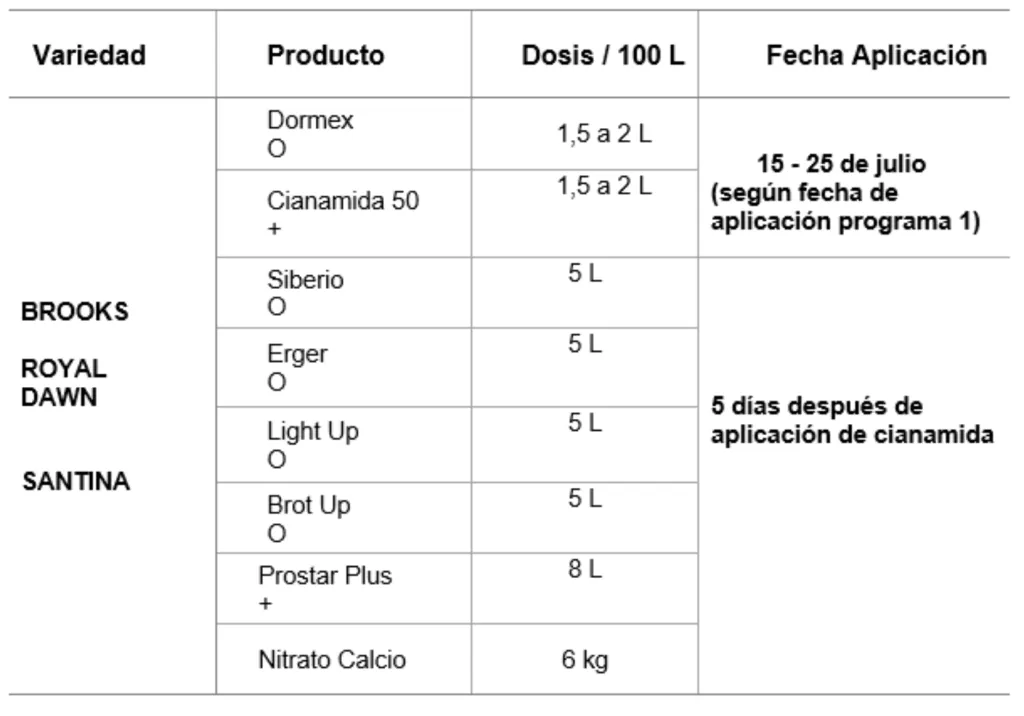

Program 1: Use of hydrogen cyanamide to anticipate bud break.

Program 1: Use of hydrogen cyanamide to anticipate bud break.

It’s important to note that Dormex or Cianamida 50 (hydrogen cyanamide) do not compensate for missing chill hours: rather, they accelerate degree-day accumulation and work through a caustic effect, burning and separating bud scales to expose internal green tissue, which absorbs heat and triggers bud break.

Given this mode of action, the product must be applied evenly without runoff to avoid phytotoxicity on spurs.

In orchards with high incidence of bacterial canker, wood diseases, or weakened plants, do not apply hydrogen cyanamide or any dormancy breaker.

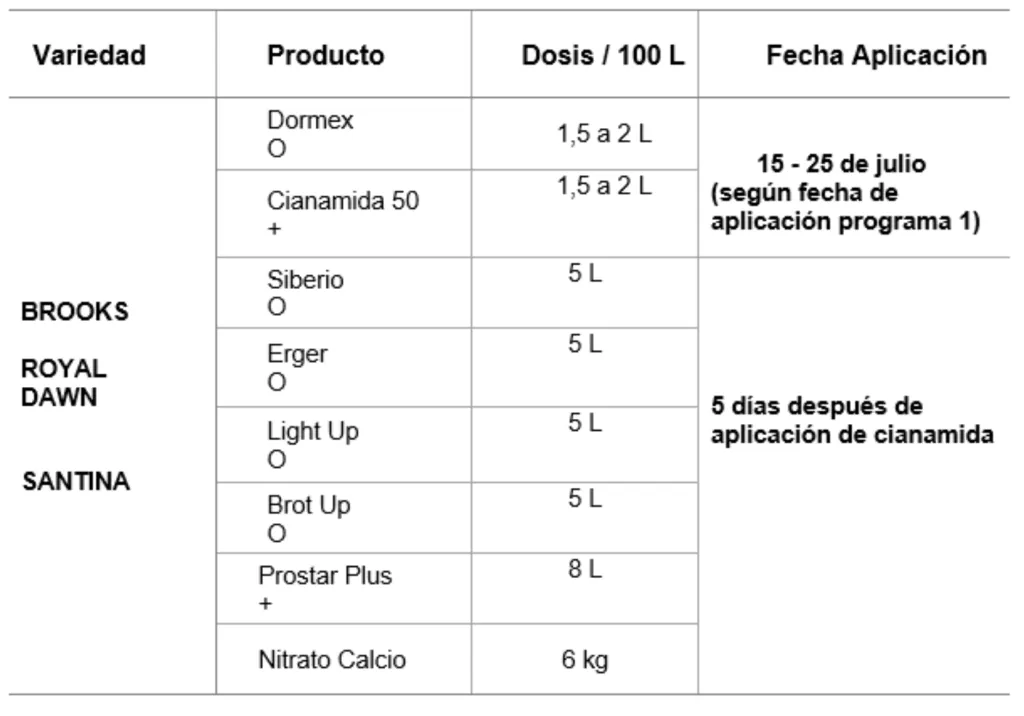

Program 2: Use of hydrogen cyanamide and bud break homogenizers to bring forward the harvest of early varieties.

Program 2: Use of hydrogen cyanamide and bud break homogenizers to bring forward the harvest of early varieties.

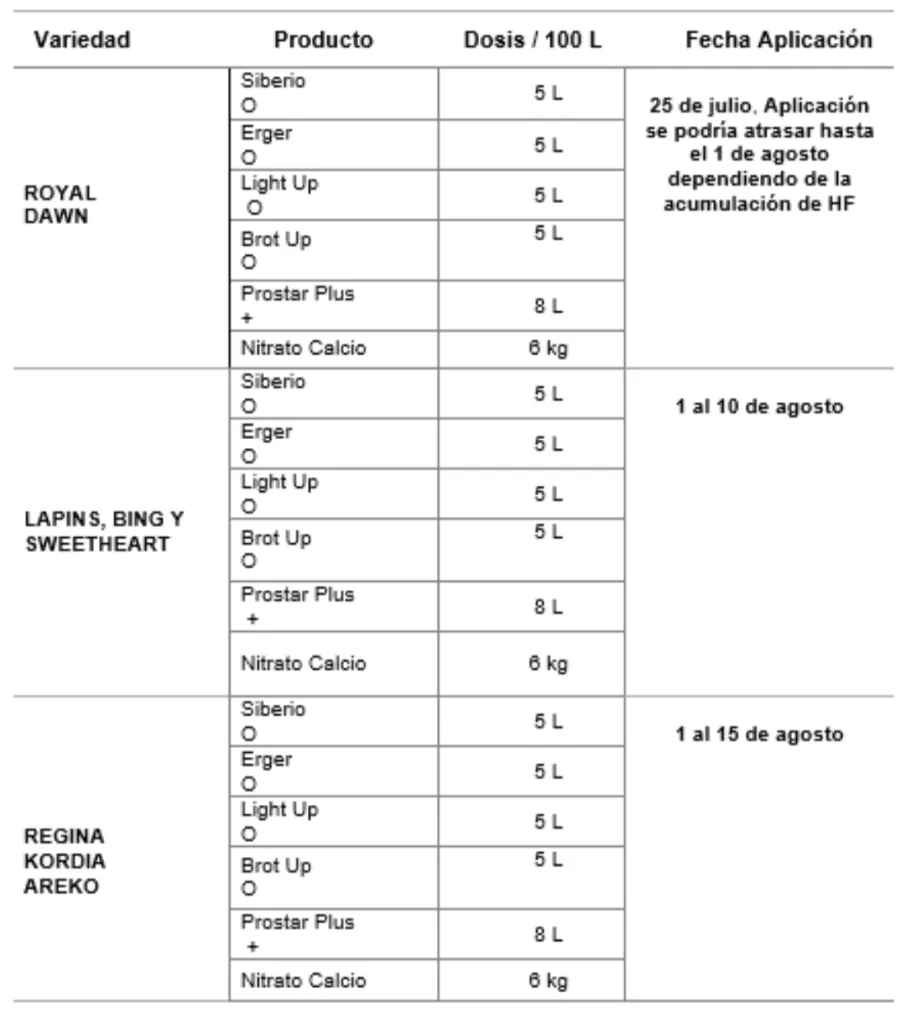

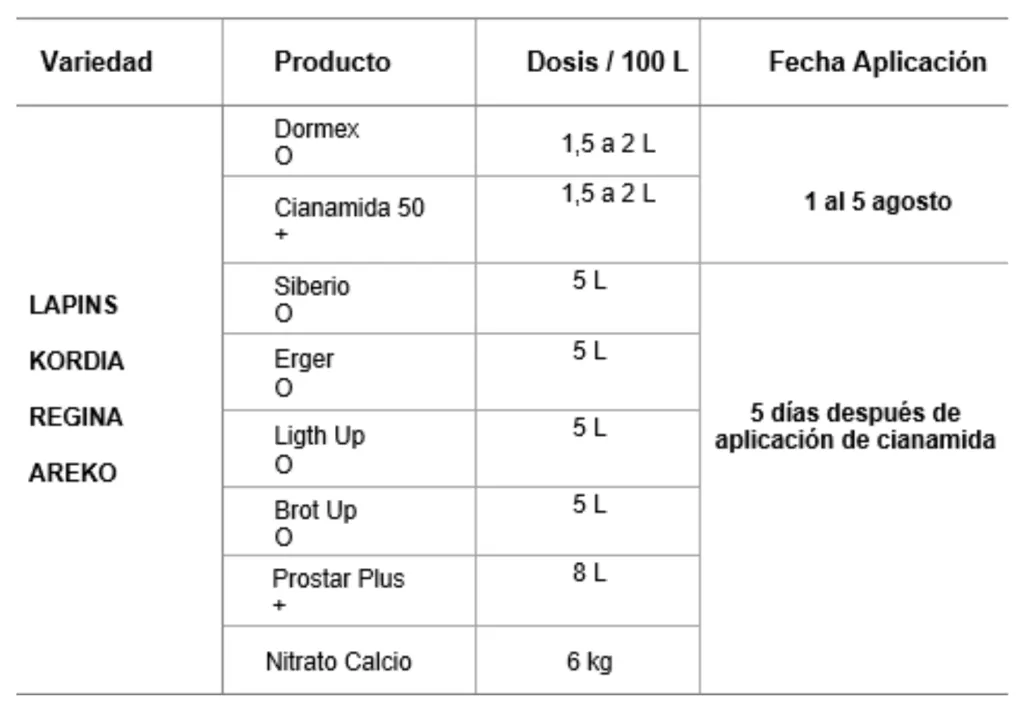

Program 3: Use of hydrogen cyanamide and bud break homogenizers to bring forward mid and late-season varieties.

Program 3: Use of hydrogen cyanamide and bud break homogenizers to bring forward mid and late-season varieties.

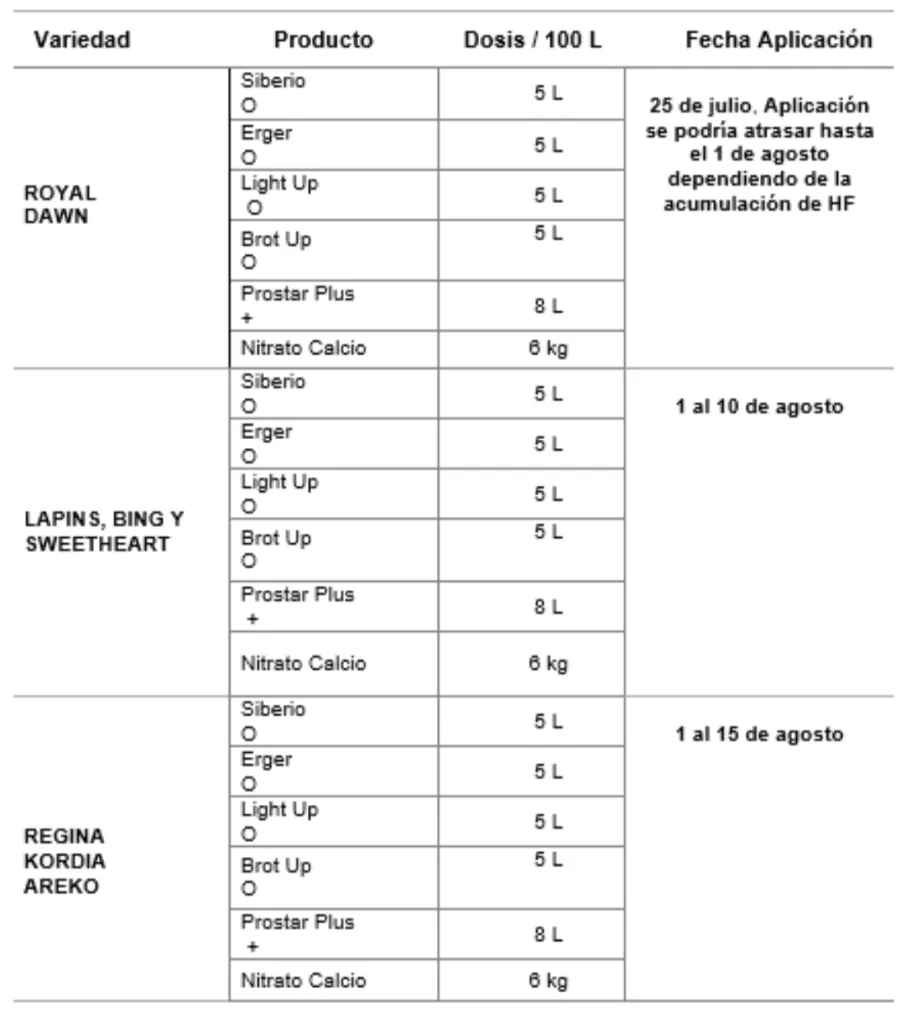

Program 4: Use of homogenizers ONLY to standardize bud break

Program 4: Use of homogenizers ONLY to standardize bud break

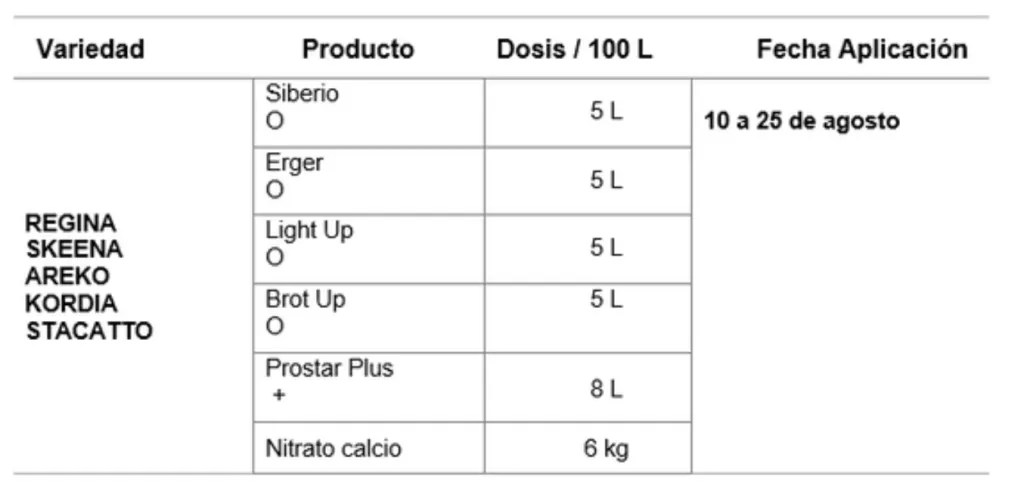

Program 5: Use of homogenizers ONLY to standardize bud break

Program 5: Use of homogenizers ONLY to standardize bud break

Application Considerations

- Do not apply unless at least 60–70% of the chill requirement for the treated variety has been reached.

- Do not apply dormancy breakers in orchards under 4 years old, with weak vigor, or with bacterial canker or wood diseases.

- Bud fertility analysis is a useful tool for verifying spur health and making objective decisions regarding application.

- For early harvest or staggering strategies, do not apply hydrogen cyanamide before July 15 on early varieties.

- Always apply at average temperatures above 13°C and ensure no rain for at least 5 hours after treatment.

- Do not repeat application if rain falls after treatment.

- Maintain label-specified concentrations: 1.5–2.5% for hydrogen cyanamide; 5% for Siberio, Erger, Light Up; 8% for Prostar Plus; 6% for calcium nitrate. All concentrations refer to 100 liters of water, depending on the commercial product.

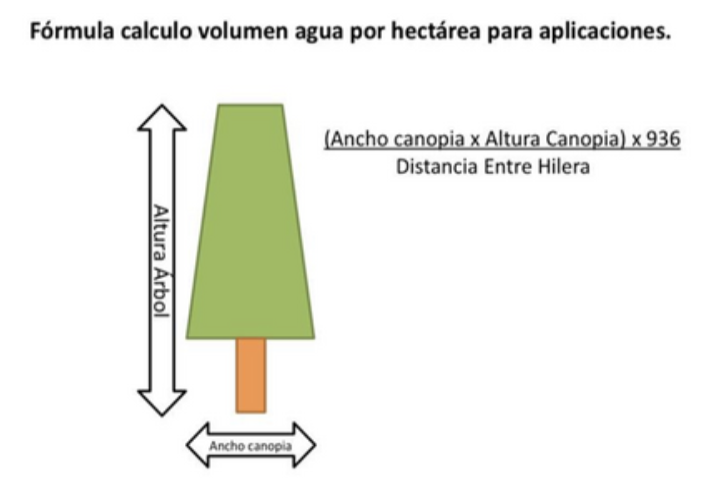

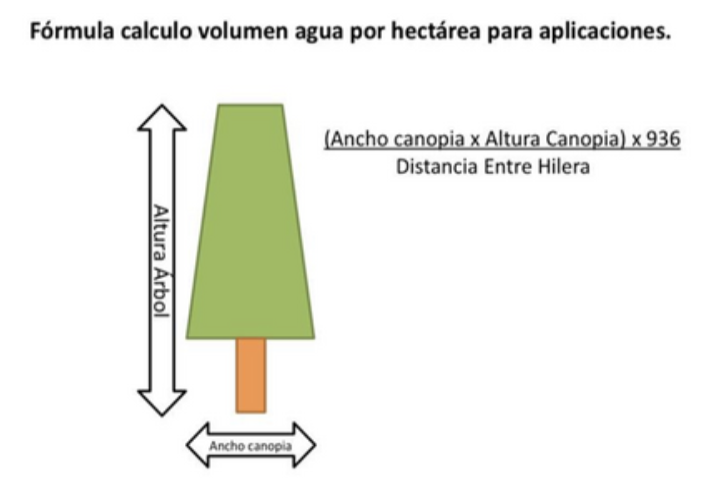

- Use adequate spray volumes to avoid phytotoxicity, applying at 70% of the Tree Row Volume (TRV).

- Ensure spraying equipment is in excellent condition and well-calibrated; avoid drips and guarantee uniform wood coverage throughout the canopy.

- Use soluble calcium nitrate, first dissolving it in 20 liters of water, then adding it to the tank mix. Foam formation is normal due to the chemical reaction.

Cover image source: SL Fruit Service

Text and image source: agroasesoria.cl

Patricio Morales

Agro Asesoria

Cherry Times - All rights reserved