From emergency to routine: in the orchards of the Pacific Northwest, night harvest is no longer an exception. Safety training, light towers, and new habits mark a major shift in agricultural labor.

With the arrival of summer, in the orchards of the Pacific Northwest (USA), workdays start earlier — and often end well after sunset. Initially a response to the extreme heat of the historic 2021 “heat dome”, night harvest has evolved into a well-established practice, especially for delicate crops like cherries.

Today, farms plan well in advance for the rental of light towers, provide workers with headlamps, and organize safety briefings specific to nighttime work. “It’s for their benefit — if we stopped working, they wouldn’t get paid,” explains Javier Ortiz, safety supervisor at Mount Adams Fruit.

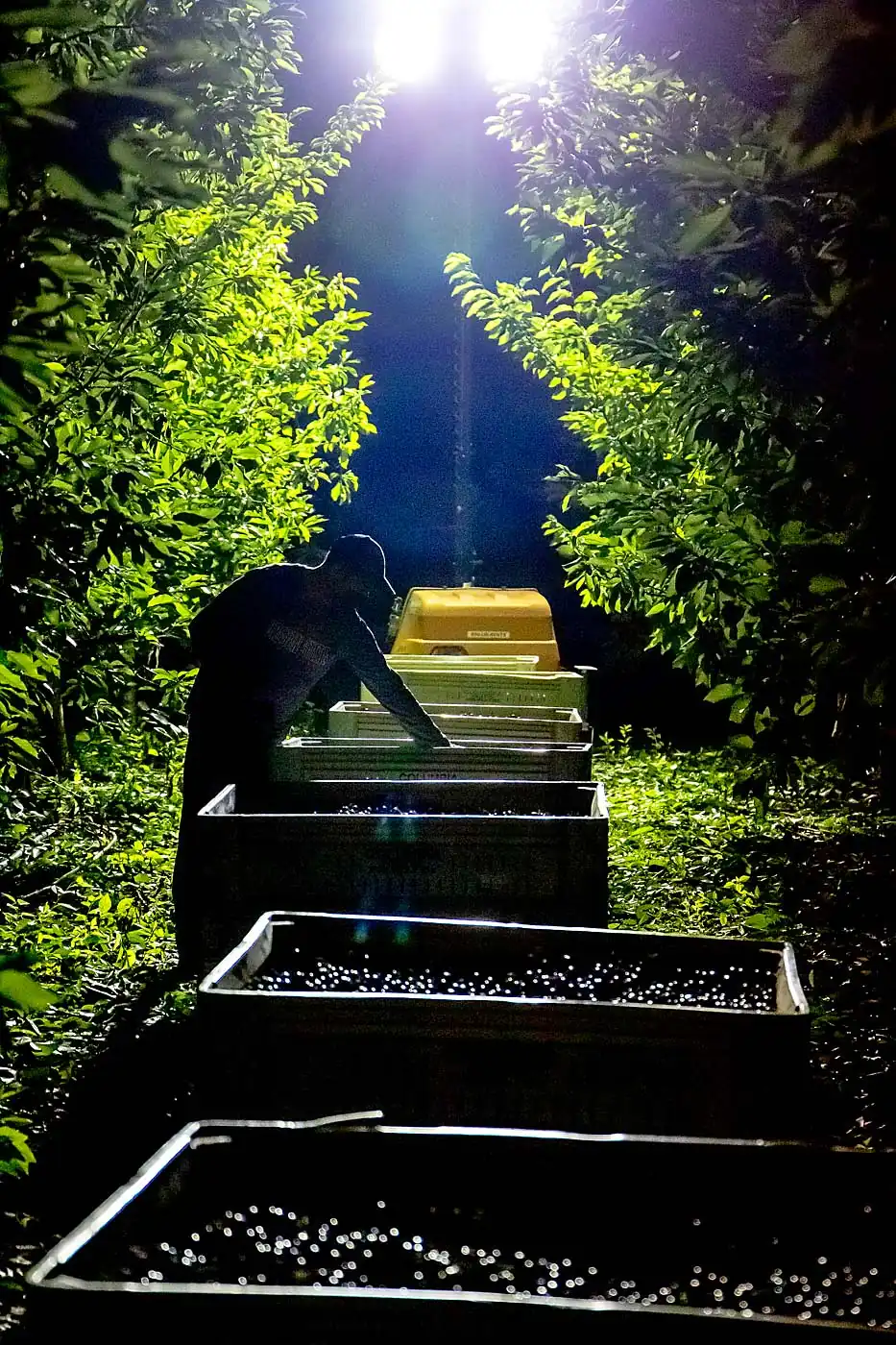

Image 1. A Stemilt Growers crew harvests apples at night on motorized platforms in 2014 near Quincy, Washington, just as a trial. However, the record heat wave of 2021 made nighttime fruit harvest more common, prompting companies to write safety protocols and train workers. (TJ Mullinax/Good Fruit Grower)

Image 1. A Stemilt Growers crew harvests apples at night on motorized platforms in 2014 near Quincy, Washington, just as a trial. However, the record heat wave of 2021 made nighttime fruit harvest more common, prompting companies to write safety protocols and train workers. (TJ Mullinax/Good Fruit Grower)

From dawn to dusk: how farm labor is changing

Although most operations still take place during daylight hours, night shifts are now considered normal, especially during peak harvest periods. “It’s become a regular conversation,” confirms Dale Goldy, owner of G2 Orchards in Mattawa, Washington.

The shift has also been accompanied by a regulatory evolution. After California adopted specific outdoor work regulations in 2006, Oregon (2022) and Washington (2023) followed with measures to protect worker health from high temperatures. Mandatory breaks, health monitoring, and proper protection are now non-negotiable requirements.

Image 2.

Image 2.

Under the beams of rented floodlights, a supervisor checks the quality of Skeena cherries during the June 2021 heatwave, known as the "heat dome". While some farms struggled at the time to find enough lights to rent, today managers often reserve them in advance at a discount — whether they end up needing them or not. (Ross Courtney/Good Fruit Grower)

Cherries at the forefront: more efficiency, less heat stress

While nighttime operations like pollination or frost protection were already common, evening harvesting is a relatively new practice. Stemilt Growers was a pioneer, testing nighttime apple harvest back in 2014 in orchards near Quincy, Washington. Today, the company also applies this approach during milder periods to better match fruit ripening schedules.

“Fruit maturity dictates the schedule. If a block is progressing fast, harvesting at night is a plus,” says Bernardo Reyes, operations manager in the Quincy area.

Cherries are the most commonly harvested crop at night, but pears are starting to be included as well, despite greater logistical challenges. Cherry harvesting is done in teams, while pear harvesting is more dispersed, with each worker managing their own bin.

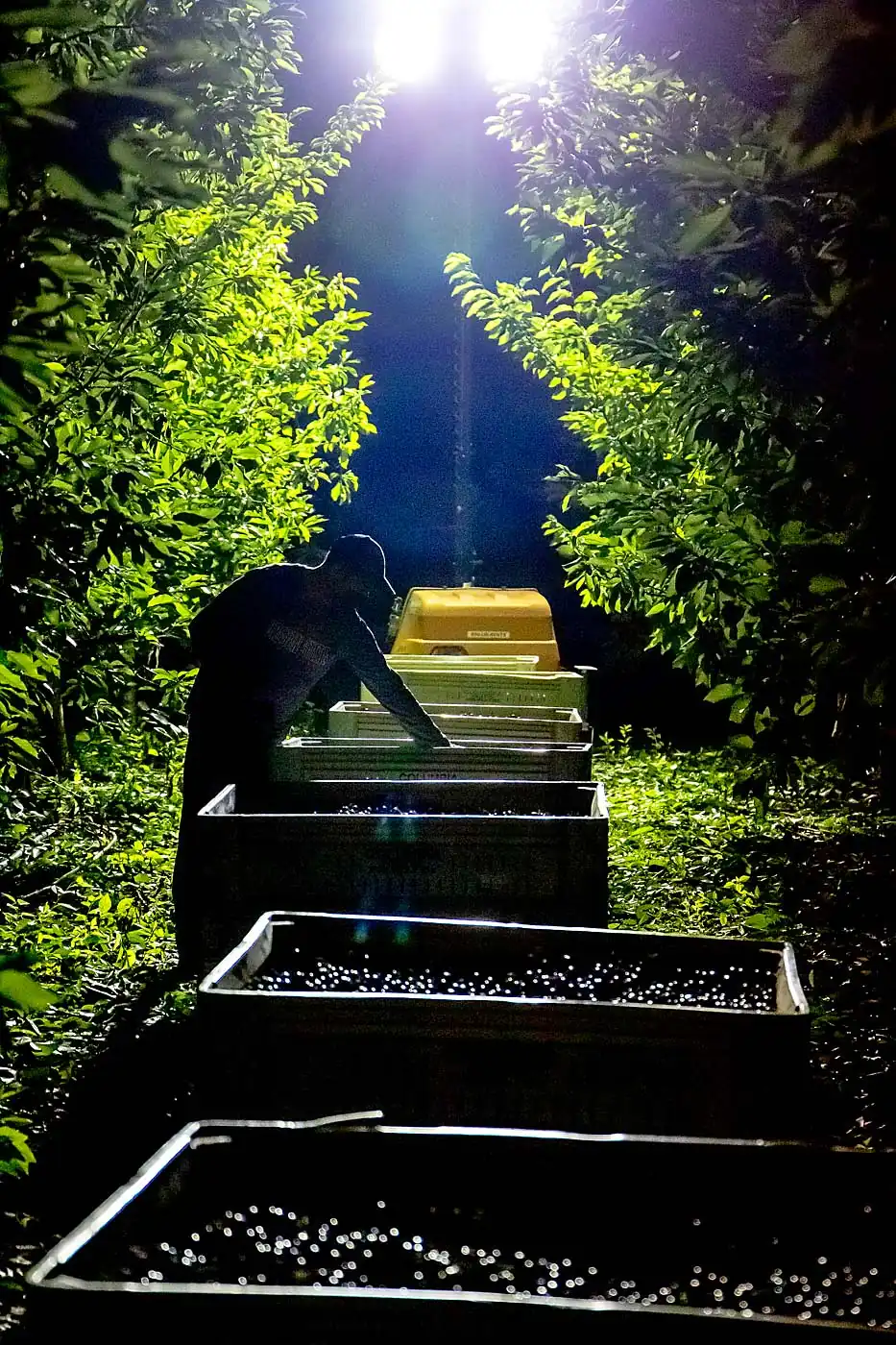

Image 3. Shadows and glare pose safety challenges at night, but managers and safety officers say that direct artificial lighting on the work area can sometimes enhance visibility. Here, Ulises Navarro, in 2014, clips fruit for Stemilt under platform lights. (TJ Mullinax/Good Fruit Grower)

Image 3. Shadows and glare pose safety challenges at night, but managers and safety officers say that direct artificial lighting on the work area can sometimes enhance visibility. Here, Ulises Navarro, in 2014, clips fruit for Stemilt under platform lights. (TJ Mullinax/Good Fruit Grower)

Safety first: visibility, training, and prevention

The lack of state-specific regulations on nighttime agricultural work doesn’t mean workers go unprotected. By law, every company must implement an injury prevention program that includes risks related to darkness.

Mount Adams Fruit, for instance, starts each night shift with a block inspection and a safety meeting. Supervisors wear reflective vests, and light towers are aimed downward to minimize glare. “We haven’t had any incidents so far,” says Ortiz, who also stresses the importance of rest before and after night shifts.

In the U.S., California is the only state with detailed rules on nighttime agricultural safety: from minimum lighting requirements in lux, to mandatory distribution of high-visibility clothing, and pre-shift briefings.

Image 4. Light towers illuminate a cherry harvest near Mattawa, Washington, in 2021. (Ross Courtney/Good Fruit Grower)

Image 4. Light towers illuminate a cherry harvest near Mattawa, Washington, in 2021. (Ross Courtney/Good Fruit Grower)

A study conducted in Oregon and published in 2020 found that nighttime work leads to more severe injuries and higher healthcare costs. However, as Eddie Kasner of the University of Washington explains, the point is not to avoid night work — but to prepare adequately.

Harvust, a platform focused on agricultural safety, has released an online guide with recommendations on visibility, rest, and the use of stimulants. A quarter of its clients have already shared it with their employees.

The future of harvest? More flexible, more smart

With climate change becoming structural, operational adaptation has become essential. What began as a temporary solution has become a strategic tool to ensure quality, safety, and consistent work.

In orchards that are increasingly illuminated and digitalized, the night is no longer a barrier, but a resource.

Source text and images: goodfruit.com

Cherry Times - All rights reserved