To preserve the quality and shelf life of sweet cherries after harvest, numerous technological innovations in packaging and preservation are being implemented. Indeed, interest is increasing in edible coatings, particularly biopolymer-based edible coatings, which are being used as alternative packaging materials.

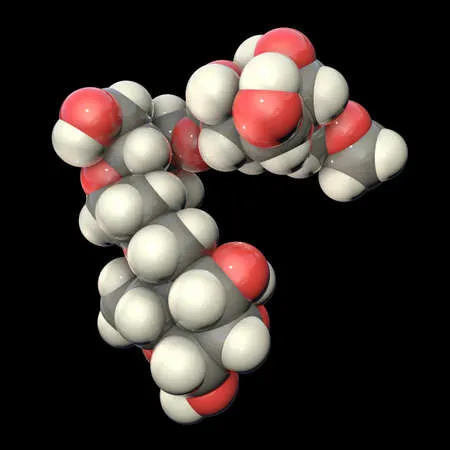

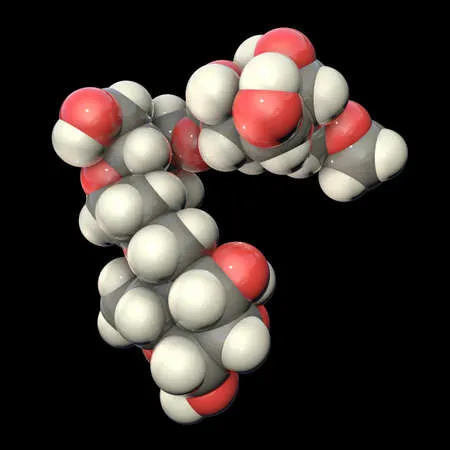

In recent years, there has been significant interest in pullulan, a polysaccharide produced through the fermentation of Aureobasidium pullulans. This is due to its potential as an ecological substrate for food coating. It is an edible, non-toxic, non-mutagenic, non-carcinogenic, non-ionic, and non-hygroscopic compound that is suitable for human consumption.

Moreover, it is odorless and tasteless. The purified form of pullulan is not widely but frequently used due to its high cost and inferior mechanical properties. Consequently, it is frequently combined with compatible polymers that are relatively less expensive and possess superior mechanical properties.

Today we present the results of a research conducted at the University of Kashmir (India) that examined the impact of pullulan and pullulan-chitosan edible coatings on the post-harvest quality of sweet cherries during a 20-day storage period.

All quality parameters were evaluated, such as weight loss, total soluble solids, color intensity, total phenolic content, flavonoids, anthocyanins, antioxidant activity, and enzymatic activity.

The results indicated that cherries with a 3% pullulan coating showed the least weight loss (25% compared to 26.33% in the control) and the lowest decay percentage (25% compared to 47% in the control) and exhibited superior firmness and stability compared to the control and other coatings tested.

Image 1: Pullulan molecule, 3D illustration.

Image 1: Pullulan molecule, 3D illustration.

In general, the coated cherries showed a smaller increase in total soluble solids content compared to the control cherries, and in particular, the cherries treated with 3% pullulan showed the smallest increase, suggesting a delayed ripening process. The 3% coating also effectively delayed the color loss of the cherries.

Moreover, the pullulan coating delayed the decrease in antioxidant activity and maintained higher levels of ascorbic acid, phenolic compounds, and flavonoids. Cherries treated with 3% pullulan showed the highest antioxidant activity (88.97%) and the highest total phenolic compound content at the end of the storage period.

The activity of the enzymes, particularly peroxidase, increased less in the coated cherries, highlighting the effect of the coatings in delaying oxidative stress. In general, pullulan coatings were the most effective in preserving quality and extending the shelf life of cherries, particularly at a concentration of 3%.

These results indicate that the application of a pullulan-based coating is a promising method for preserving product quality during storage, thus extending their shelf life. By maintaining quality and reducing post-harvest losses, these coatings can help improve economic gains, increase consumer acceptability, and reduce food waste.

Future research should focus on formulation, consumer acceptability, and scalability to optimize pullulan-based coatings for their commercial application.

Source: Shoib M. Wani, Danish Rizwan, F.A. Khanday, Sajad A. Mir, F.A. Masoodi, Effect of pullulan and pullulan-chitosan composite coating on the antioxidant activity, texture, color and shelf-life of a local cultivar of sweet cherry, Food and Humanity, Volume 3, 2024, 100432, ISSN 2949-8244, https://doi.org/10.1016/j.foohum.2024.100432.

Images: SL Fruit Service; DR MICROBE

Melissa Venturi

University of Bologna (IT)

Cherry Times - All rights reserved