Wastewater from the fruit processing industry still contains a significant amount of bioactive substances, which can represent an important resource if properly recovered.

Within the framework of sustainability and the circular economy, these by-products should not be considered simple waste, but rather potential sources of valuable compounds that can be extracted and reused before the final treatment of the wastewater.

The application of integrated management strategies can in fact reduce the sector’s environmental impact, generate economic benefits, and contribute to the preservation of water resources.

Supercritical fluids and extraction

To recover these substances, one environmentally friendly technique involves the use of supercritical fluids.

These are substances brought to conditions of temperature and pressure above their critical points—that is, beyond the values at which it is no longer possible to distinguish between the liquid and gaseous phases.

In this state, the fluid exhibits intermediate properties between those of a gas and a liquid: it has the density of a liquid, allowing it to dissolve many substances, but also the low viscosity and high diffusivity of a gas, which facilitate penetration into materials and molecular transport.

A widely used example is supercritical CO₂, which is obtained by bringing carbon dioxide above 31.1 °C and 7.38 MPa (megapascal ≈ 73 atm).

Applications and benefits

Under these conditions, CO₂ becomes an effective, non-toxic, non-flammable solvent that can be easily separated from the final product simply by reducing the pressure.

For these reasons, it is extensively employed to extract aromas, essential oils, natural pigments, and bioactive substances from plant matrices, as well as for the decaffeination of coffee and tea.

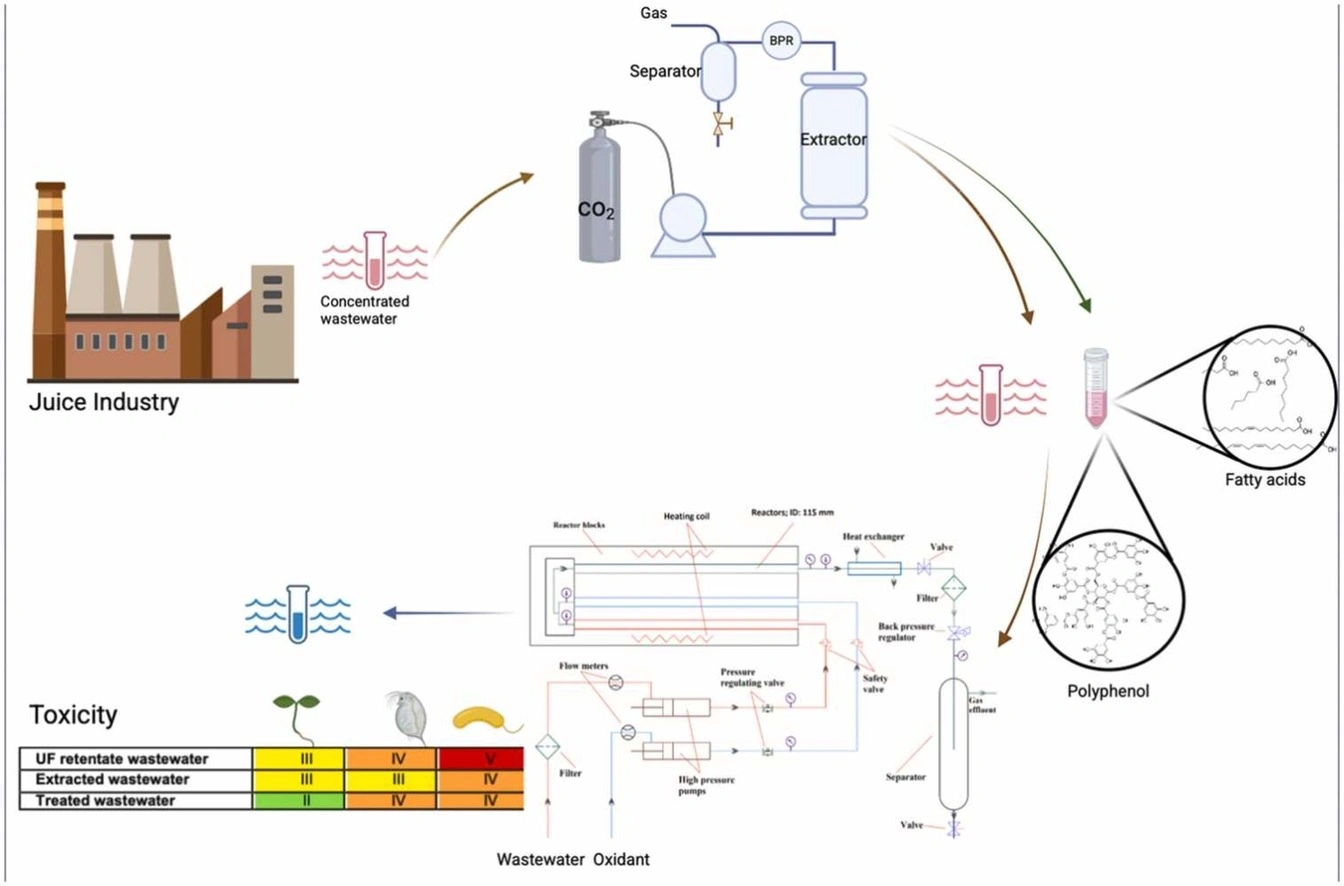

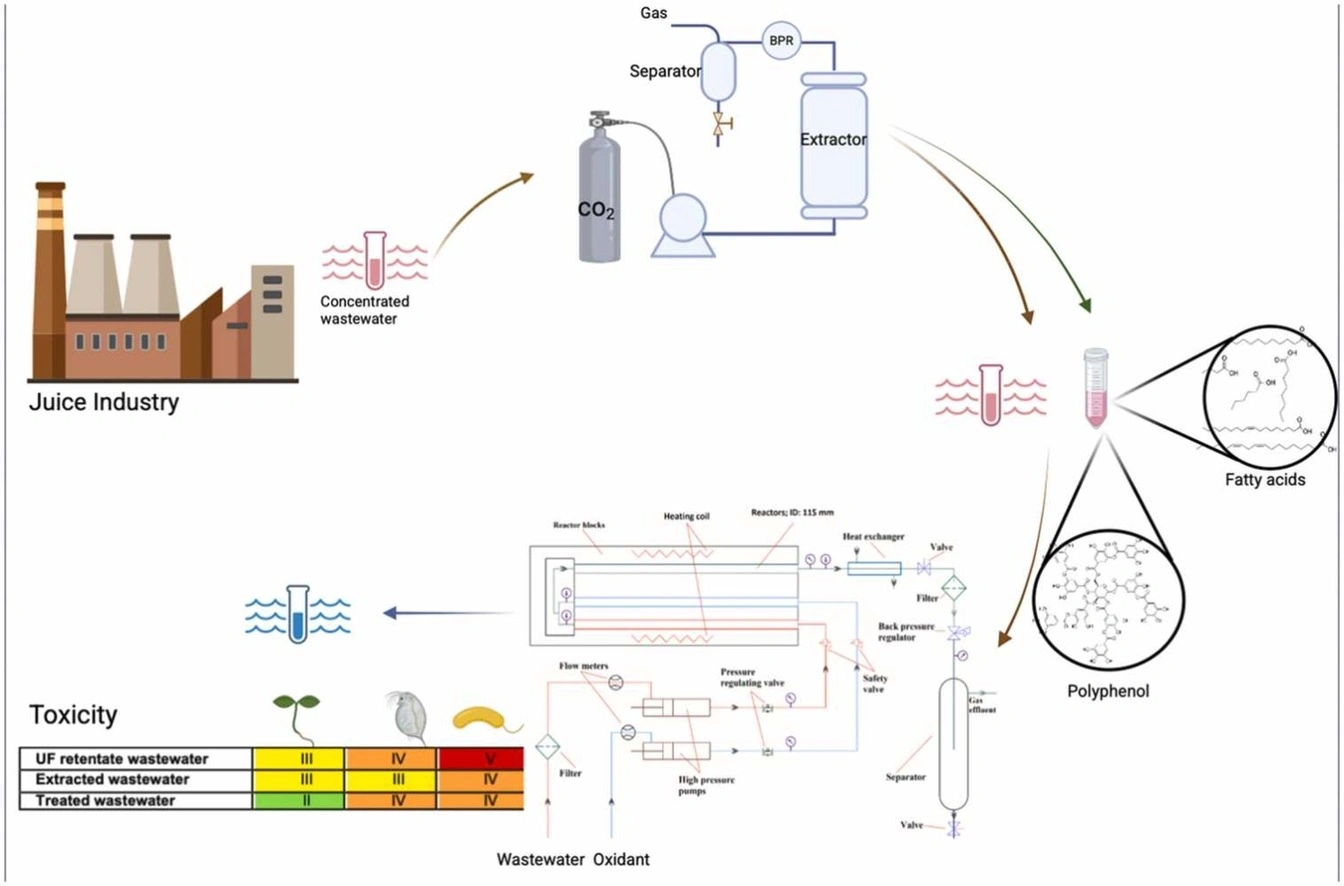

In this study, conducted in Turkey, the possibility of combining two processes based on the use of supercritical fluids was explored: extraction with supercritical carbon dioxide (SC-CO₂) and oxidation in supercritical water (SCWO).

Experimental results

The starting material was an ultrafiltration concentrate of sour cherries, characterized by a high content of organic matter and, in particular, of valuable phenolic compounds.

The chemical oxygen demand (COD) was measured at 15,650 mg/L, while the concentration of total phenolic compounds reached 457 mg GAE/L.

During the supercritical CO₂ extraction phase, the recovery yields of total phenolic compounds and total flavonoids were up to 5% and 10%, respectively, with maximum enrichment efficiencies of 35% and 140%.

The total phenolic content, which was 72 mg per 100 g of sample in the raw material, increased to 278 mg/100 g in the extract obtained at 40 °C and 30 MPa.

Oxidation and final results

Flavonoids, compared to other phenolic groups, showed greater solubility and therefore better recoverability under SC-CO₂ extraction conditions.

Subsequently, the residual extraction waters were treated using the supercritical water oxidation process.

This method made it possible to eliminate most of the organic load in a very short time (about 15 minutes), with removal efficiencies ranging from 78% to 98%.

Even at low oxidant doses, the process remained highly effective, achieving more than 70% COD removal.

The results showed a decrease in toxicity units in both the extracts and the treated waters compared to the raw wastewater, under optimal extraction conditions.

Overall, the collected data demonstrate that supercritical fluid technology represents an innovative and promising approach for the valorization of wastewater from the fruit juice industry.

Source: JOUR, Management of sour cherry processing industry wastewater by super critical fluid method: Sequential recovery and treatment, Argun, M. Emin, Ateş, Havva, Argun, M. Şamil, Cakmakci, Özgür, Process Safety and Environmental Protection, 199, 107318, 2025, 2025/07/01/, 0957-5820, https://doi.org/10.1016/j.psep.2025.107318

Image Source: Qualigeo

Source figure: Argun et al., 2025

Melissa Venturi

University of Bologna (IT)

Italian Berry - All rights reserved