Dehydration damage is not always immediately evident. In many cases, its effects appear at the destination: dehydrated stems, softer fruit, loss of marketable weight, or a generally less fresh appearance.

This sequence of deterioration is not random, and understanding its causes makes it possible to make informed decisions for its mitigation.

The moment of truth

The boxes are finally opened. After weeks of waiting, Chilean cherries arrive on the other side of the world, ready to face their toughest test: the gaze of the Asian buyer.

At that instant, every detail matters. The color, the flavor, the size, the shine, the firmness of the fruit… but above all, the green stem and the firmness to the touch.

Because it is not enough to have produced a good cherry, nor to have harvested it at the optimal time. What really matters is how it arrives. And it does not always arrive as expected.

Often, after a promising season and exemplary agronomic management, cherries arrive showing signs of fatigue: wilted stems, loss of firmness of the flesh, and an appearance that, while not necessarily indicating a loss of wholesomeness, still casts doubt on their freshness.

A complex chain

Where was that quality lost? Valentina Vesely. The answer is not found in a single link in the chain, but in the sequence of stages that make up postharvest.

From the moment the fruit is detached from the tree until the box is opened at its destination, the cherry goes through a complex journey: time in the field, local transport, waiting periods at the processing facility, and the long export voyage.

Each of these stages takes place in a different environment, with variable temperatures, humidity levels, and durations, all silently but cumulatively contributing to a common enemy: dehydration.

This article aims to understand how dehydration affects the condition of cherries at destination, and why even small water losses can translate into significant commercial losses.

Data and tools for prevention

Based on trials carried out by the R&D Department of Proyectos Industriales Johnson, we will explore the evidence directly linking dehydration with variations in weight, firmness, and visual appearance of the fruit, and analyze which tools are currently available to mitigate this silent deterioration.

The cherry’s journey

The cherry is a fruit particularly vulnerable to water loss due to its anatomical structure: thin skin, high surface-to-volume ratio, and limited presence of natural barriers to transpiration.

This condition makes it susceptible to dehydration, even after brief exposures to unfavorable environmental conditions of temperature and humidity.

During postharvest —the process from field harvest to arrival at the export market—, cherries go through several stages: waiting in the orchard after harvest, on-farm storage, transport to the processing center, reception at the packinghouse, cold storage before processing, and sea transport to the destination.

Each of these stages presents specific environmental conditions and, in many of them, controlling relative humidity is not considered a priority variable in conventional postharvest management.

Understanding the risk

A key technical tool for understanding and quantifying the risk of dehydration is the vapor pressure deficit (VPD). This variable combines air temperature and relative humidity and allows estimation of the vapor gradient between the fruit and its surrounding environment.

The higher the VPD, the faster the flow of water from the fruit to the environment, increasing the rate of dehydration.

And although water loss may seem moderate in each stage when considered individually, its cumulative effect can seriously compromise essential attributes of cherries.

Dehydration damage is not always immediately evident. In many cases, its effects appear at the destination: dehydrated stems, softer fruit, loss of marketable weight, or a generally less fresh appearance.

This sequence of deterioration is not random, and understanding its causes makes it possible to make informed decisions for its mitigation.

Manifestations of dehydration in cherries: beyond water loss

Weight loss: the first symptom

Water loss in cherries during postharvest translates directly into weight loss. Unlike other symptoms that require specific evaluations or sensory perception, weight variation can be precisely measured at every stage of the process, allowing detailed tracking of the progress of dehydration.

This loss occurs cumulatively along the entire postharvest chain, from harvest to arrival at the destination. Already in the orchard, the fruit begins to dehydrate while waiting between rows before being taken to the collection center.

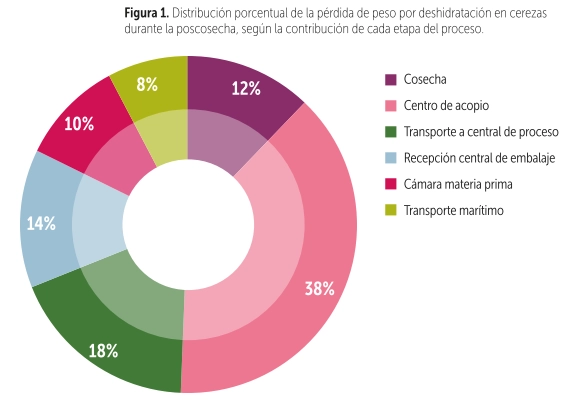

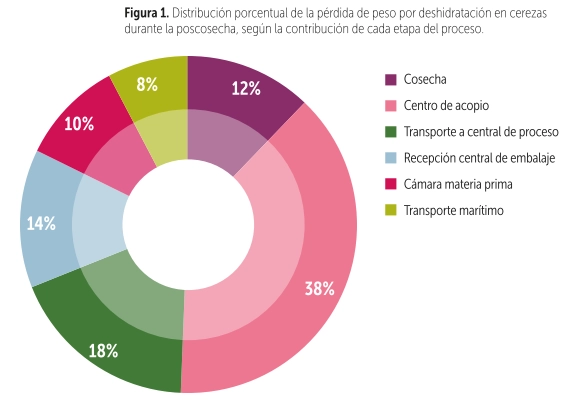

At that initial moment, exposed to sun or wind, water loss begins, which can intensify if waiting is prolonged or if there are no adequate protection conditions. This stage can account for up to 12% of the total postharvest dehydration (Figure 1).

Figure 1. Percentage distribution of weight loss from dehydration in cherries during postharvest, according to the contribution of each process stage.

Figure 1. Percentage distribution of weight loss from dehydration in cherries during postharvest, according to the contribution of each process stage.

Later, at field collection centers, fruit may remain for several hours before being loaded onto trucks heading to the processing and packing facility. These facilities, often lacking environmental control, present high temperatures and low relative humidity, conditions that favor a high vapor pressure deficit (VPD) and continuous transpiration.

If no measures are taken to mitigate this effect, the stop at the collection centers can account for up to 38% of the total weight loss from dehydration, making it the stage with the greatest impact in the entire process.

The most critical stages

Transport to the facility, although generally shorter, also contributes to water loss, especially if the fruit is not adequately protected, and can represent about 18% of total dehydration.

The reception area, before entering the hydrocooler, becomes a critical point: the operational bottleneck, frequent at this stage, can keep the fruit exposed for hours under unfavorable conditions.

This step, often underestimated, accounts for 14% of observed dehydration. After hydrocooling, the fruit is stored in raw material cold rooms, where low temperature helps slow down dehydration but does not eliminate it completely, especially if relative humidity is not adequately controlled.

Depending on waiting time, this stage can contribute around 10% to total water loss.

Finally, maritime transport to the destination —although carried out under refrigeration and with the use of modified atmosphere bags— involves prolonged exposure to low but constant dehydration rates. In this final stage, about 8% of total loss is estimated to occur.

At the end of the postharvest process, the cumulative effect of all these stages can translate into weight losses of around 3–4% compared to the initial fruit weight, as observed in trials conducted under commercial conditions.

This decrease not only affects the net exported weight but also becomes the physiological basis for other quality loss symptoms that will manifest later, such as stem browning or loss of firmness.

Stem browning: a visible symptom of dehydration

The most evident sign of dehydration-related deterioration in cherries is stem browning. Even if the fruit maintains apparent firmness, the brown color of the stem is immediately perceived by the consumer.

This visual change, the consequence of a physiological process triggered by accumulated water loss during postharvest, is immediately associated with reduced freshness.

The stem, like the fruit, loses water through transpiration, but it does so even more markedly due to its smaller volume and larger exposed surface area.

When VPD is high and persists for extended periods, the tissue loses turgidity, dehydrates, and activates oxidative processes that lead to pigment degradation and the appearance of brown shades.

Experimental evidence

Experimental evidence confirms this. Trials conducted by the R&D Department of Proyectos Industriales Johnson demonstrated a direct relationship between fruit dehydration (measured as percentage weight loss) and stem deterioration.

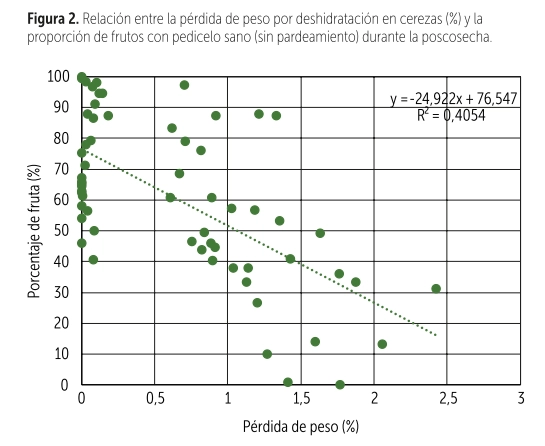

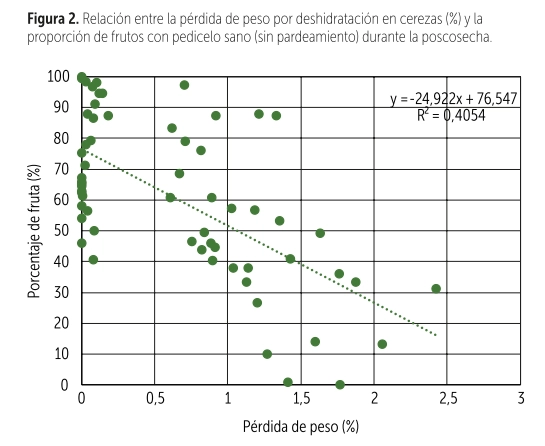

Figure 2. Relationship between weight loss from dehydration in cherries (%) and the proportion of fruit with healthy stems (without browning) during postharvest.

Figure 2. Relationship between weight loss from dehydration in cherries (%) and the proportion of fruit with healthy stems (without browning) during postharvest.

In Figure 2, it can be seen that the percentage of cherries with a “healthy” (fully green) stem decreases as water loss increases.

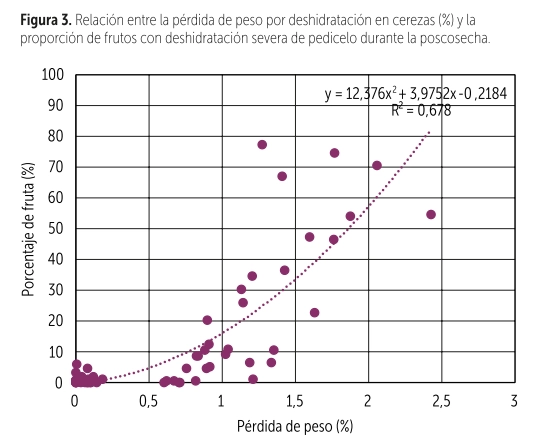

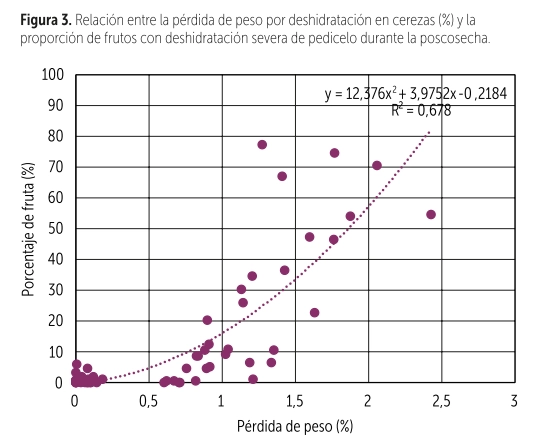

Complementarily, Figure 3 shows how the percentage of cherries with severely dehydrated stems —completely browned— increases with dehydration.

The observed model suggests that, although the first levels of water loss do not cause evident damage, there is a threshold beyond which stem deterioration accelerates rapidly.

Figure 3. Relationship between weight loss from dehydration in cherries (%) and the proportion of fruit with severe stem dehydration during postharvest.

Figure 3. Relationship between weight loss from dehydration in cherries (%) and the proportion of fruit with severe stem dehydration during postharvest.

It is important to note that the data presented in both figures refer to evaluations carried out on different cherry varieties. This genetic diversity explains the scatter observed among points, as each variety may react differently to water loss.

However, beyond such variability, the common trend is clear: the greater the dehydration, the greater the stem deterioration, both in terms of intensity and frequency.

These observations allow us to affirm that the stem is not only a visual indicator of the fruit’s condition but also a variable particularly sensitive to postharvest management, especially to VPD conditions in the early stages of the process.

Maintaining environments with high relative humidity can significantly reduce this type of damage, improving the perception of freshness at destination and, consequently, the commercial acceptance of the fruit.

Loss of firmness: a less visible but equally critical effect

Unlike stem browning, loss of firmness in cherries is not always visually perceptible, but it has a decisive impact on the sensory quality of the fruit.

This variable is crucial both for the consumer’s experience and for the product’s shelf life, and is strongly influenced by the fruit’s water status.

Firmness largely depends on cellular turgor, maintained by the water content in the tissues. When cherries lose water during postharvest, the internal pressure of the cells decreases, weakening tissue structure and resulting in a softer texture.

This loss of firmness is not due solely to ripening processes or enzymatic degradation, but also —and significantly— to the direct physiological effect of dehydration.

Relationship between weight loss and firmness

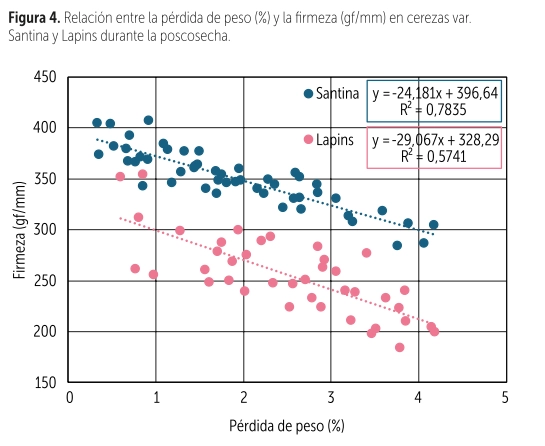

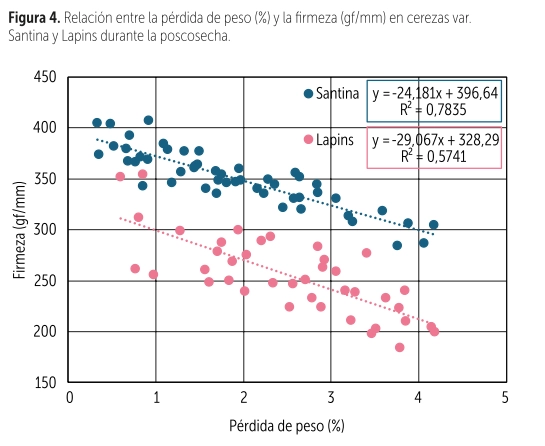

In Figure 4 this relationship is clearly visible: as the percentage of weight loss increases, fruit firmness decreases.

Figure 4. Relationship between weight loss (%) and firmness (gf/mm) in Santina and Lapins cherries during postharvest.

Figure 4. Relationship between weight loss (%) and firmness (gf/mm) in Santina and Lapins cherries during postharvest.

The data, obtained from a trial conducted on ‘Lapins’ and ‘Santina’ cherries, show a linear trend that confirms the existence of a consistent relationship between the two variables.

Although the slope is not steep, it indicates that each percentage point of weight loss results in a measurable reduction in firmness.

Based on this relationship, it can be estimated that when the fruit loses 4% of its weight during the entire postharvest period —a value close to the average observed under commercial conditions— firmness decreases by about 100 gf/mm.

This drop is significant considering that the acceptable firmness range for export is narrow, and any reduction can make the difference between a lot being accepted or rejected at the destination.

A risk to perceived quality

These results reinforce the idea that dehydration, although not visually evident in its early stages, compromises key attributes of export cherries.

Reduced firmness increases the risk of mechanical damage during transport and lowers fruit acceptance at destination, especially in demanding markets such as Asia, where firmness is a highly valued attribute.

Together with the results observed in the stem, loss of firmness completes the picture of dehydration-induced postharvest deterioration.

Both variables —one visual and the other structural— have the same physiological origin: the progressive loss of water in an environment with a high vapor pressure deficit.

Protecting the value built throughout the season

The journey of cherries from orchard to export market is full of silent challenges. Among them, dehydration represents one of the most insidious: it advances unnoticed in its early stages but leaves a visible and measurable mark at the end of the process.

Browned stems, loss of firmness, and weight reduction are not isolated defects, but cumulative physiological manifestations of a postharvest chain that still needs to optimize its relationship with water.

The results presented in this article derive both from real commercial management conditions and from trials in which the fruit was exposed to different dehydration scenarios.

This combination made it possible to technically understand how small variations in the postharvest environment can trigger significant effects on the final fruit quality.

The quality of cherries begins long before harvest. It is the result of constant work throughout the season, integrating agronomic decisions, orchard management, and rigorous technical monitoring.

Safeguarding those attributes during postharvest also means protecting the value of all that effort.

Minimizing dehydration not only preserves the commercial value of the fruit but also the time, knowledge, and resources invested in achieving its size, firmness, flavor, and visual appeal.

Adopting effective mitigation measures, such as controlling vapor pressure deficit, is a concrete tool to ensure that effort is not lost along the way.

And in an increasingly demanding market, it is not enough to produce a good cherry: it is necessary to ensure it arrives in its best version.

Active VPD management and commitment to environmental control in postharvest are now strategic decisions that determine success at destination.

Opening image source: SL Fruit Service

Figures source: Redagricola

Valentina Vesely

Director of Research and Development

Johnson Industrial Projects

Cherry Times - All rights reserved