Last year, we shared how CSIRO was developing an automated, non-destructive pest detection system to help the cherry industry meet increasing biosecurity and export market demands.

Since then, the technology has advanced from a promising proof-of-concept to a robust, real-time detection system that is now ready to work with partners in addressing the challenges the industry is facing.

From laboratory to packhouse

Over the past year, the CSIRO team has worked closely with industry partners, including AgTech manufacturers, to test the optical detection system in operational environments.

These trials have demonstrated promising progress toward real-time analysis of high-resolution images without slowing sorting operations.

The upgraded system can now process more than 30 frames per second with a total end-to-end latency of just 27 milliseconds per frame, allowing seamless operation alongside commercial graders.

Importantly, the system maintains stable performance under varying lighting conditions and fruit orientations, making it adaptable to real-world variability in postharvest lines.

Smarter, faster, and more resilient

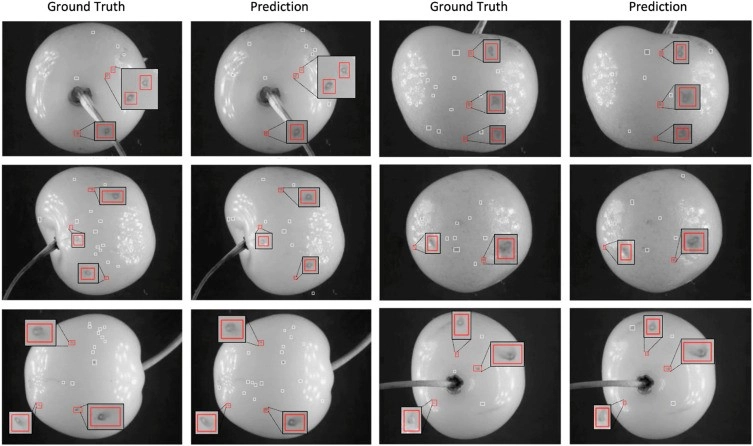

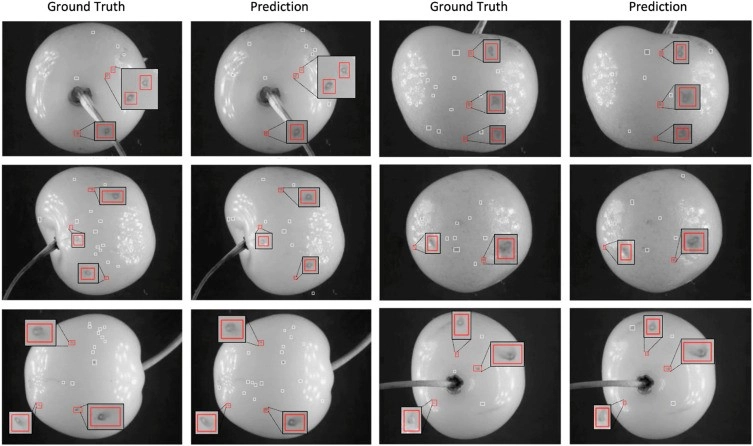

The new capabilities mean the system can more reliably identify fruit fly stings, even when fruit rotates or moves across the field of view (Figure 1) — reducing false detections and ensuring consistent accuracy.

This improvement is powered by advances in object tracking and cherry-specific machine learning features that make the technology smarter and more responsive to real-world conditions.

Figure 1: Automated optical scans of cherry fruit showing AI detected pest damage and rotation.

Figure 1: Automated optical scans of cherry fruit showing AI detected pest damage and rotation.

At the same time, the system has been designed to easily handle the high throughput typical of commercial grading environments.

Its flexible, event-driven software architecture prevents processing bottlenecks, improves fault tolerance, and allows resources to be allocated efficiently — all contributing to faster, more reliable operation at scale.

Towards industry deployment

The next phase of development focuses on integrating the CSIRO detection system with existing optical grading technology, enabling packhouses to automatically identify and remove infested fruit in real time.

This will enhance the quality and compliance of export shipments, minimise costly rejections, and strengthen the reputation of Australian cherries in global markets.

Beyond the packhouse, the system also has the potential to transform border inspection processes — allowing for faster, cheaper, more consistent, and non-destructive inspection of imported and exported produce.

By providing regulators with objective, data-driven tools, the technology contributes to a more efficient and evidence-based approach to managing biosecurity risks.

A collaborative path forward

The ongoing success of this technology depends on collaboration across the supply chain — from growers and packers to exporters and regulators.

CSIRO continues to work with partners to refine, validate, and scale up the system for different commodities and pest types.

The ultimate goal remains the same: to deliver a fully automated, non-destructive biosecurity inspection system that enhances Australia’s capacity to manage trade-related pest risks, reduce regulatory costs, and sustain global competitiveness.

As the cherry industry looks toward the 2025–26 season, these advancements bring us one step closer to a future where technology, science, and trade work seamlessly together — creating not only a more efficient but also a more secure pathway for Australian produce to reach the world.

As the project leader, I welcome insights and feedback from cherry growers and packhouses about this initiative.

Image source: CSIRO

Dr Maryam Yazdani

Team Leader, Pest Detection Technologies

Health & Biosecurity, CSIRO

maryam.yazdani@csiro.au

Cherry Times - All rights reserved