The choice of the training system is a fundamental decision that defines much of the productive and economic success of the orchard.

Each architecture must be carefully selected according to the variety/rootstock combination, fruiting habit, soil and climatic conditions, availability and cost of labor, as well as the grower’s technical and economic capacity.

Training systems and productivity

There is no single standard training system.

Cherry training systems in Chile and their characteristics

October 1, 2025 – Marlene Ayala and Andrés Valenzuela

The choice of a well-adapted and properly managed training system provides benefits to orchard productivity throughout its useful life. For this reason, it is essential to understand that each species has a growth and fruiting habit that naturally gives it a specific architecture. The grower must know it thoroughly before implementing any type of formation.

Whether it is a central leader system, a trellis variant, or a multi-leader system, the application of the species’ physiological principles must form the basis for managing the variety/rootstock combination, also taking into account local soil and climate conditions and labor availability.

The variety guides the system

The training system adapts to the variety, not the other way around.

First, the variety to be grown is chosen, then the most suitable rootstock, and finally the training system. The latter must be functional to the chosen variety, depending on the area and the target market.

The fruiting habit and floral biology of a given cherry variety provide indications of its productivity, but yield and quality will also be influenced by the rootstock vigor and the genetic interaction between the two. It is therefore essential to understand this interaction in order to choose the most suitable training system.

There is no “standard” training system for every variety/rootstock combination.

Agronomic and management factors

The tree’s behavior in relation to a given architecture depends on multiple factors. Soil characteristics, for example, greatly affect plant vigor. Added to this are strategies of fertilization, irrigation, and pruning, which play a decisive role in the success of the adopted system.

A key element in choosing the system is the availability of local labor, on which the efficiency of agronomic operations such as thinning and harvesting depends. Two other crucial factors are the grower’s economic capacity and technical skills to implement and manage the chosen system.

Training systems used in Chilean cherry orchards

Central leader system

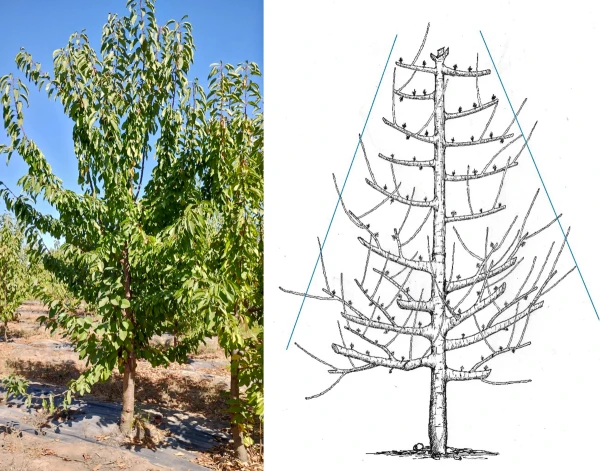

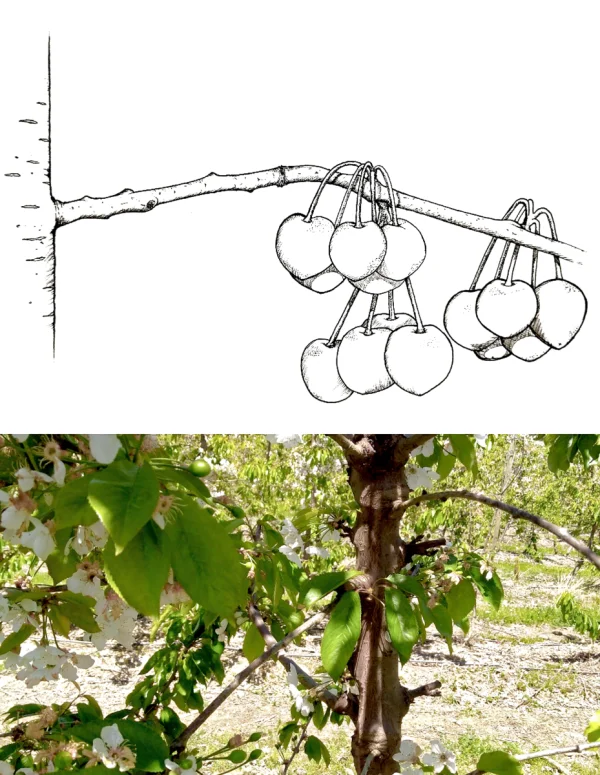

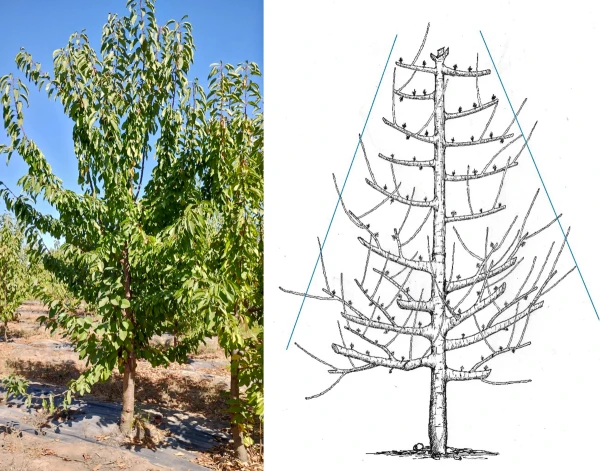

It is one of the most widespread in Chilean commercial orchards. The canopy, three-dimensional, consists of a single axis, from which primary branches depart, branching into secondary and tertiary ones, forming the productive unit: shoots with fruiting spurs and vegetative spurs distributed on wood of different ages, and one-year shoots emerging from wood that is 1, 2, or more years old (Fig. 1).

The structure is arranged in “layers” along the axis, with decreasing age toward the top, taking on a semi-conical shape. Primary branches are often bent into more horizontal positions to facilitate the formation of layers and fruiting spurs.

The relatively “free” form of the central leader makes the structural maintenance of the system less strict.

Figure 1. Chilean central leader system

Figure 1. Chilean central leader system

However, this very feature means that operations such as pruning, thinning, and harvesting require a greater amount of labor compared to other training systems, since the canopy grows in height and volume, making the use of traditional ladders mandatory.

The central leader is mainly formed through a heading cut performed during the first winter, aimed at favoring the formation of primary branches. The response in terms of branching may vary depending on the vigor of the chosen variety/rootstock combination and its degree of acrotony (apical dominance influencing lateral branching along the axis). An alternative is to avoid heading the leader and instead promote bud break through notching and the use of growth regulators.

A common practice in the Chilean central leader system is the use of growth regulators (cytokinins and gibberellins) combined with phloem incisions along the axis, at the level of vegetative buds at the “green tip” stage (Fig. 2).

Figure 2. Use of growth regulators to stimulate lateral bud break

Figure 2. Use of growth regulators to stimulate lateral bud break

Tree architecture management

After bud break, branch bending is often applied to place the primary branches in a more horizontal position (between 60° and 90°) and arrange them into “layers” with differentiated vigor. In general, the number of primary branches varies from 15 to 22 along the axis, depending on the tree height (between 2.8 and 3.5 m). The branches of the lower layers must be stronger and more permanent than those of the upper layers, which are younger and renewed more frequently (Fig. 3).

Figure 3. Bending of primary branches in the central leader system

Figure 3. Bending of primary branches in the central leader system

In this system it is essential to control vigor in the upper part of the tree, since water sprouts develop that shade the base of the primary branches, causing the death of fruiting spurs.

The central leader system is semi-precocious and can be adopted with practically any variety/rootstock combination (e.g., Lapins/Colt, Lapins/Gisela®6, Santina/MaxMa14), making it a flexible system to implement.

Planting distances vary from 2.0 to 3.0 m in the row and from 3.5 to 4.0 m between rows, corresponding to densities ranging from 800 to 1,400 trees/ha.

Limitations of the central leader system

Disadvantages of the central leader system

Among the disadvantages are:

- Greater labor requirement, due to the complexity of operations (especially harvesting);

- Large canopy volume, which can cause excessive shading inside the plant if a conical shape is not maintained;

- Difficulty in branching for variety/rootstock combinations with a strong acrotonic tendency.

V and Y Trellises

“V” TRELLIS AND “Y” TRELLIS

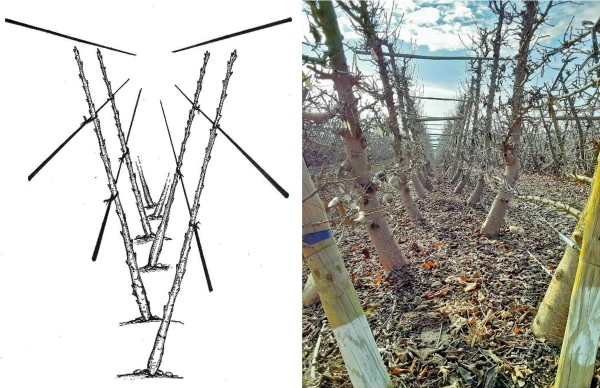

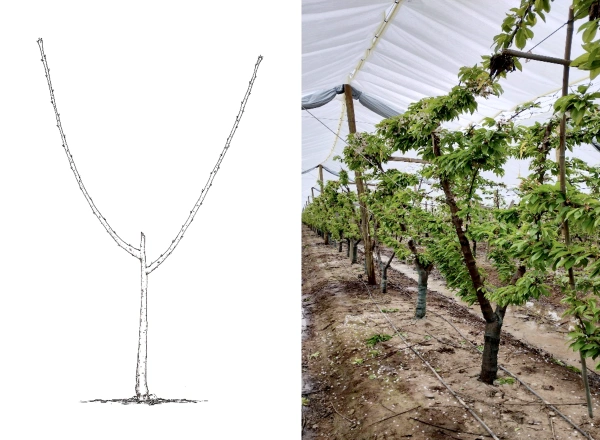

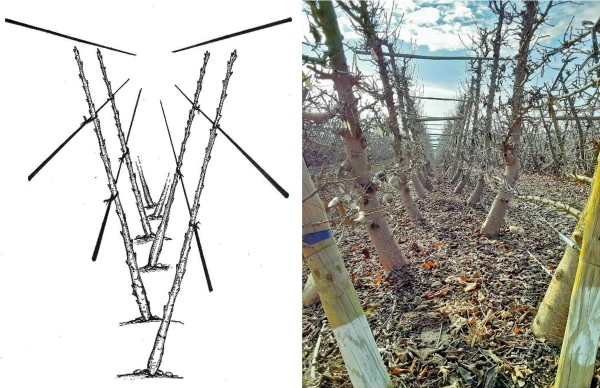

Trellis systems are based on the concept of a fruiting wall, formed by an inclined axis with primary branches arranged horizontally. They are distinguished by the double flat canopy architecture, which generates a “V” or “Y” shape along the row. These systems allow the creation of semi-pedestrian orchards, with different applicable variants.

One variant involves planting trees with trunks inclined at 60° from the horizontal. The trees are alternately tilted toward the two interrows. This configuration is known as the “V-Trellis” (Fig. 4a).

The other variant uses trees from which two main axes develop in opposite directions, also inclined at about 60° from the horizontal. Due to the tree’s morphology, this system is called the “Y-Trellis” (Fig. 4b).

Figure 4a. Trunks inclined toward the interrow: V-Trellis

Figure 4a. Trunks inclined toward the interrow: V-Trellis

Figure 4b. Trunks inclined toward the interrow: Y-Trellis

Figure 4b. Trunks inclined toward the interrow: Y-Trellis

In both variants, the branches emerging from the main axes are inclined horizontally along the row, forming two thin and parallel “fruiting walls.” These systems place a strong structural demand on the plants, so support structures with wires and posts are always required. Recently, these structures have been simplified through the use of coligüe canes and “gareta” tapes.

Trellises are recommended for rootstocks of medium or medium-high vigor (e.g., Maxma 14, Colt), adjusting the opening angle of the V or Y (narrower or wider depending on vigor). In the case of medium-low vigor rootstocks (e.g., Gisela®6, Gisela®12), renewal of the horizontal branches is more difficult, due to the high presence of blind nodes and the low response to lateral bud break after pruning cuts.

Recommended combinations and densities

In Central Chile, better performance has been observed with:

- self-sterile varieties (e.g., Regina) on semi-vigorous rootstocks (e.g., Gisela®12)

- self-fertile varieties (e.g., Lapins) on more vigorous rootstocks such as Colt

With the latter, blind nodes are fewer and renewal of horizontal branches is better, thanks to a greater response to heading cuts.

In trellis systems, good management of lighting in the upper part of the tree is essential, to avoid shading at the base of the axis. For this reason, summer pruning may be necessary before and after harvest.

Planting density

V-Trellis:

Densities from 1,700 to 3,000 trees/ha,

with in-row spacing from 0.9 m to 1.4 m,

and 3.5–4 m between rows.

Y-Trellis:

Densities from 1,400 to 2,000 trees/ha,

with in-row spacing from 1.2 m to 1.8 m,

and 3.5–4 m between rows (depending on tree height).

All these parameters vary according to the adopted variety/rootstock combination (Fig. 5).

Figure 5. Front view of cherry trees trained with V-Trellis (top) and Y-Trellis (bottom)

Figure 5. Front view of cherry trees trained with V-Trellis (top) and Y-Trellis (bottom)

Number of branches and advantages of trellises

The number of horizontal branches may vary, but a good balance has been observed with 6–7 branches per side of the inclined axis, of which 15–20% must be renewed annually.

Among the advantages of these systems are:

- Earlier bearing

- Ease of pruning and harvesting, with the use of shorter ladders

- Thin and flat architecture, allowing the use of harvesting platforms and pruning mechanization

The main critical issue is represented by the planting costs, linked to the high plant density and the need for posts and support wires.

In the case of combinations with high productivity but low vigor, renewal of horizontal branches is difficult and these systems are not recommended.

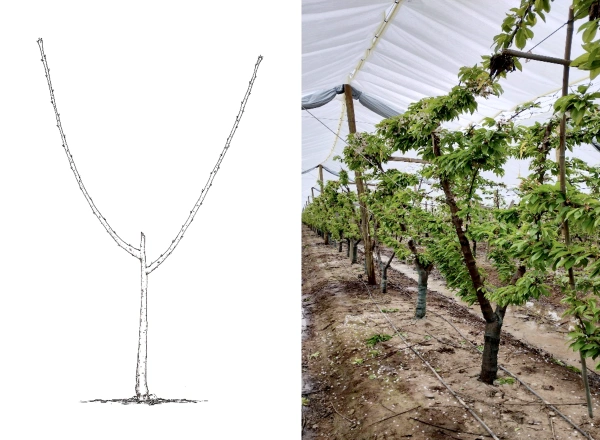

Kym Green Bush: “KGB”

The KGB is the only training system that falls into the “pedestrian” category, with pruning, thinning, and harvesting operations performed from the ground. The canopy consists of multiple vertical axes, each carrying active fruiting spurs every season. Annual lateral shoots must be removed.

The vertical axes emerge from a low trunk, which does not exceed 80 cm. This architecture greatly facilitates cultural practices such as pruning, thinning, and harvesting (Fig. 6). During harvest, the vertical axes can be bent directly by the picker, without the need for ladders.

Figure 6. ‘Lapins’ variety on Colt rootstock in KGB system

Figure 6. ‘Lapins’ variety on Colt rootstock in KGB system

It requires multiple flexible yet resistant axes, capable of sustaining the fruit load.

The main advantages of KGB include:

- High labor efficiency

- Reduced risk of injuries

- Lower planting costs, thanks to the absence of posts and wires

KGB system management

The system is mainly structured through three heading cuts (Fig. 7), which reduce precocity. Various factors (rootstock, variety, soil type, area) can influence shoot emission from the crown; in some cases, a fourth cut may be necessary, further delaying entry into production.

Figure 7. Heading cut for the formation of the KGB system

Figure 7. Heading cut for the formation of the KGB system

Three or four cuts are carried out to obtain the desired number of vertical axes.

Once all axes are formed, summer topping is required to:

- Maintain the tree height

- Eliminate apical shoots that shade the base

This is essential to promote the annual renewal of vertical axes.

Rootstocks of medium or high vigor are recommended, ideally grafted with self-fertile and upright-growing varieties. Planting distances range from:

- 2.0 to 2.5 m in the row

- 3.5 to 4.0 m between rows

This corresponds to densities ranging from 1,000 to 1,400 trees/ha.

The use of weak rootstocks favors excessive fruit load, which compromises axis renewal due to competition between fruit and new shoots. In such combinations, targeted thinning of spurs may be necessary.

In central Chile, recommended combinations include:

- Self-fertile varieties rich in spurs (e.g., Lapins, Sweetheart)

- Vigorous rootstocks (e.g., Colt)

The number of vertical axes varies according to the combination, ranging from 12 to 20. About 15–20% of them are renewed each winter, to stimulate the production of new shoots from the crown (Fig. 8).

Figure 8. Crown of the KGB system

Figure 8. Crown of the KGB system

Base trunk from which all axes originate during the system’s useful life.

Balance and critical issues in the KGB system

Managing balance in the KGB system

If the tree is unbalanced, plants with excessive vigor may be observed, characterized by very upright axes, larger diameter, and strong vegetative growth (commonly called “males”). These shoots must be removed, as over time they cannot be bent and will not produce sufficient fruit.

Conversely, too weak vigor in the vertical axes (defined as “females”) may cause excessive fruit set, leading to overloading that bends branches, while also hindering renewal of shoots due to internal competition (Fig. 9).

Figure 9. KGB system with bent axes due to low vigor and fruit overload

Figure 9. KGB system with bent axes due to low vigor and fruit overload

Among the disadvantages of KGB are:

- Lower precocity, due to heading cuts

- Progressive rigidity of vertical axes (compromising pedestrian use over time)

- Reduction in the number of vertical branches with age

- Poor lighting in the crown area

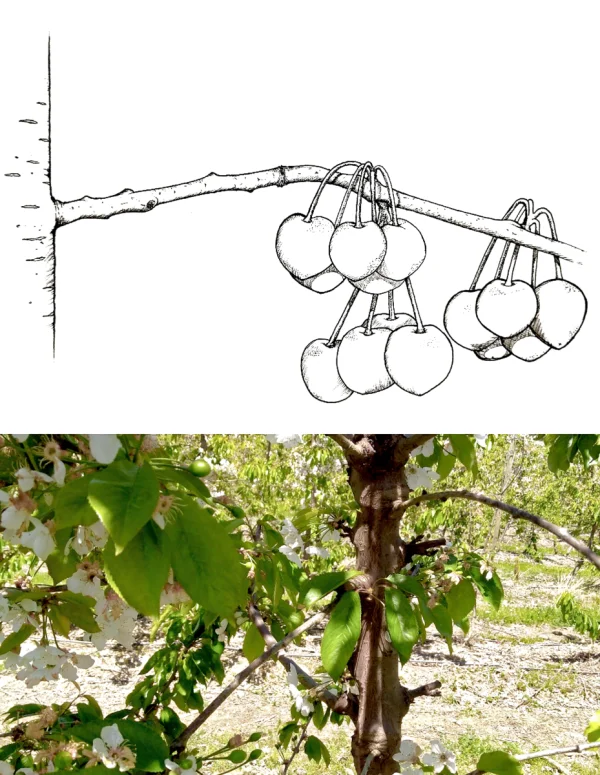

Upright Fruiting Offshoots: “UFO”

The UFO system is a two-dimensional (wall) system, which in its productive stage forms a true “fruiting wall” with high precocity. It is composed of several upright vertical axes that bear fruit exclusively on spurs (lateral shoots are removed), facilitating harvest through quick fruit access, improving lighting, and making pruning and thinning faster and more efficient (Fig. 10).

Figure 10. Young cherry trees trained in the UFO system, forming a fruiting wall

Figure 10. Young cherry trees trained in the UFO system, forming a fruiting wall

The management of the UFO system, especially during the formation phase, must be precise and timely, to obtain vertical axes from an axis inclined at 45°, which must then be maintained even in the productive phase (Fig. 11).

Since the system’s architecture involves an inclined axis from which vertical axes emerge, the system is not self-supporting and requires support structures with multiple wires and posts, leading to higher initial costs.

The upright vertical axes, generally 6 to 8 per plant, are renewed by 20–25% each year, eliminating the more vigorous ones or those with exhausted spurs.

In general, the use of semi-vigorous rootstocks, such as the Gisela® series and Maxma 14, combined with spur-bearing and upright varieties (e.g., Lapins) is recommended. Some soil-climatic areas in central Chile allow the use of more vigorous rootstocks (e.g., Colt), but with caution, to avoid excessive vigor of the axis.

Spacing and critical issues of the UFO system

Spacing and density of the UFO system

- In-row spacing: 1.2 to 1.8 m

- Between-row spacing: 3.0 to 4.5 m

- Density: 1,200 to 2,700 trees/ha

The UFO system often requires crop load regulation at the spur level, through flower and/or fruit thinning (Fig. 11).

Figure 11. Inclined axis with vertical development of fruiting axes

Figure 11. Inclined axis with vertical development of fruiting axes

In central Chile, difficulties are observed in renewing vertical axes in combinations with medium or low vigor rootstocks (e.g., Gisela®6, Gisela®12), due to the formation of weak and overloaded branches, subject to the formation of blind nodes during seasonal changes.

Among the disadvantages of the UFO system are:

- Need for posts, wires and ties (with frequent fastening and re-fastening of axes)

- High management costs in the orchard formation phase

- Exposure of the inclined axis to direct solar radiation, which can cause wood sunburn, bud death, and pathogen entry

An effective solution consists of applying sun protectants or reflective paints directly on the exposed wood.

In cold areas, it is important to protect against frost, since a significant part of the woody structure and buds is located close to the ground, making the system more sensitive to frost, especially during the wall formation stage.

UFO system variants

There are also variants of the simple UFO system. In some vigorous combinations, it is possible to develop a V-shape on the horizontal axis, called “double UFO” (Fig. 12). This architecture requires high-vigor combinations.

Figure 12. Different perspectives of the “double UFO” variant

Figure 12. Different perspectives of the “double UFO” variant

Among the advantages of the UFO system are:

- High precocity in production

- Ease of harvesting

- Possibility of mechanizing some operations such as pruning

However, this structure also presents some weaknesses, including:

- Higher initial investment for posts and support wires

- Uneven bud break during plant formation

- In the production stage, difficulties in renewing vertical axes in some variety/rootstock combinations

Tall Spindle Axis: “TSA”

The TSA system is a variant of a narrow, conical central leader, without the use of support wires or posts. From the main axis (2.5–3.2 m high), a continuous spiral of 18–20 medium-vigor primary branches develops (Fig. 13). The TSA system allows the adoption of semi-pedestrian orchards, increasing labor efficiency, as operations can be carried out with short ladders.

It is an early-bearing system. The lower yield per tree is compensated by a higher planting density. The recommended distances are:

- 1.5–1.8 m in-row

- 3.0–4.0 m between rows

Total density: 1,400–2,200 trees/ha

Figure 13. Cherry trees trained with the TSA system

Figure 13. Cherry trees trained with the TSA system

It includes winter heading cuts and winter renewal of primary branches.

The TSA is suitable for semi-vigorous rootstocks such as:

- Maxma 14

- Gisela® series (e.g., Gisela® 6, Gisela® 12)

In combination with self-sterile or self-fertile varieties with balanced fruit set (e.g., Regina, Santina).

With self-sterile varieties, good fruit quality is often obtained. With more productive varieties, careful management with specific pruning and flower/fruit thinning will be necessary.

The basic productive unit in TSA consists of a spur segment with two lateral shoots below the heading cut (Fig. 14). The pruning protocol includes:

- Winter heading cuts on one-year-old wood to concentrate productive spurs

- Moderate summer pruning, especially in the upper part of the tree, to allow light penetration

Figure 14. Basic productive unit of TSA

Figure 14. Basic productive unit of TSA

It includes heading a shoot to obtain elongated shoots and concentrated production in a short spur-bearing segment.

During TSA formation, it is necessary to select uniform shoots along the axis, to create a conical spiral structure. However, in some combinations the following can be observed:

- Uneven bud break (e.g., on Colt)

- Insufficient bud emission (e.g., on Gisela® 6), especially in areas with low winter chilling accumulation

In such cases, the use of notching combined with growth regulators is recommended to stimulate better spring bud break.

In the production stage, the priorities become:

- Annual renewal of about 20% of branches on the axis

- Maintaining vigor in new shoots below the heading cut

- Crop load regulation through winter pruning and thinning

A key aspect is keeping the top of the tree light, to avoid shading of lower leaves.

Disadvantages of the TSA system

One of the main problems is the difficulty of renewing branches directly from the axis, due to the formation of blind nodes (scars without meristems), which develop where fruit was set and prevent the growth of new branches (Fig. 15). This happens because the vegetative buds, from which the new branch should develop, are located too far from the trunk.

Figure 15. Blind nodes in TSA system

Figure 15. Blind nodes in TSA system

These hinder the renewal of branches directly from the main axis.

Super Slender Axis: “SSA”

The SSA system is a variant of a very narrow and thin central leader (Super Slender), with very high precocity. From the axis emerge 18 to 25 low-vigor primary branches, which will produce fruit at their base (Fig. 16). The SSA allows the establishment of very early semi-pedestrian orchards. In most cases, a short ladder or platforms are sufficient for harvesting, making it very convenient.

The key management practice consists of annual renewal of one-year-old branches, to concentrate production as close as possible to the axis, or even directly on the axis itself. It is a system suited to medium-low vigor rootstocks, such as Maxma 14 and the Gisela® series, in combination with self-sterile or partially self-fertile varieties (e.g., Regina, Kordia, Santina).

Figure 16. Cherry trees trained with SSA system. Allows high density per hectare

Figure 16. Cherry trees trained with SSA system. Allows high density per hectare

Planting distances vary between:

- 0.7 – 1.0 m in-row

- 3.0 – 4.0 m between rows

→ generating high densities, from 2,500 to 4,700 trees/ha

As with TSA, the lower yield per tree is compensated by the higher density.

In most cases, SSA requires a support system, because the trees have a reduced permanent structure and a limited root system.

For combinations with self-sterile varieties, higher fruit quality is often obtained compared to combinations with more productive and/or self-fertile varieties. The latter will require careful crop load control with pruning and spur-level thinning, to avoid a reduction in the leaf:fruit ratio and tree weakening.

Once in production, the system requires the annual renewal of 30–40% of branches.

The percentage is high, since fruit must always be produced at the base of the current year’s shoot.

This involves a marked heading cut above the two vegetative buds closest to the trunk, with the aim of obtaining a new productive shoot for the following spring.

One of the disadvantages of SSA is the difficulty of renewing branches, due to poor shoot emission from the axis and the formation of blind nodes at the base. The tendency to produce blind nodes and the effect of crop load reduce vegetative response, especially in years of high fruit load.

Figure 17. Blind nodes extending non-productive wood from the central axis in the SSA system

Figure 17. Blind nodes extending non-productive wood from the central axis in the SSA system

Over time, this leads to shoots increasingly distant from the trunk and weaker (Fig. 17).

A critical point to consider is the higher initial cost for plants and support structures, since it is an ultra-high-density system.

A choice that defines productive success

The choice of the cherry training system is a fundamental decision, conditioning much of the orchard’s productive and economic success throughout its useful life.

There is no single or standard system: each architecture must be carefully chosen based on:

- the variety/rootstock combination

- the fruiting habit

- the soil and climatic conditions

- the availability and cost of labor

- the grower’s technical and economic skills

Systems like the Central Leader offer flexibility and adaptability, but require more labor for pruning and harvesting.

V or Y trellises improve efficiency and mechanization, but require support structures and constant renewal of branches.

The KGB system stands out for its pedestrian format, which reduces costs and improves operational safety. However, the lower precocity and the difficulty of renewing axes in some combinations require strict management of vigor and fruit load.

The UFO system ensures high precocity and great efficiency in harvesting and pruning, thanks to the fruiting wall structure, but requires:

- precise formation

- support structures

- it is subject to renewal difficulties with low-vigor rootstocks

Finally, high-density systems such as TSA and SSA offer maximum precocity, excellent yield per area, and ease of management, but require:

- strict vigor control

- continuous renewal of fruiting branches

The training system must always be at the service of the variety, and not the other way around.

Proper implementation requires:

- in-depth knowledge of cherry physiology

- an integrated approachthat considers:

- desired architecture

- tree vigor

- light interception

- branch renewal

- crop load regulation

Only in this way can an optimal balance be achieved between:

- yield

- fruit quality

- resource use efficiency

resulting in a sustainable and competitive orchard over time.

Opening image source: SL Fruit Service

Internal images source: Redagricola

Marlene Ayala and Andrés Valenzuela

Redagricola

Cherry Times - All rights reserved