In the post-harvest handling of cherries, the cold storage phase prior to packing represents a critical node where multiple environmental factors converge, directly influencing weight loss, stem condition and, ultimately, commercial quality.

Although its role is often considered secondary to hydrocooling or transport, this stage largely determines the physiological fate of the fruit.

The interaction between vapor pressure deficit (VPD), air circulation, thermal gradients and spatial heterogeneity within a conventional cold room can turn the cold environment into a highly dehydrating context.

With the aim of characterizing this behavior and assessing the role of humidification, the PIJ R&D Department conducted an experimental trial to understand how different microenvironments affect fruit condition during the waiting period before processing.

Study conditions and methodology

The study was carried out on ‘Santina’ cherries immediately after hydrocooling, stored for eight days under two different environmental conditions:

- Conventional cold room (without humidification)

- Cold room with high-pressure humidification (95% RH)

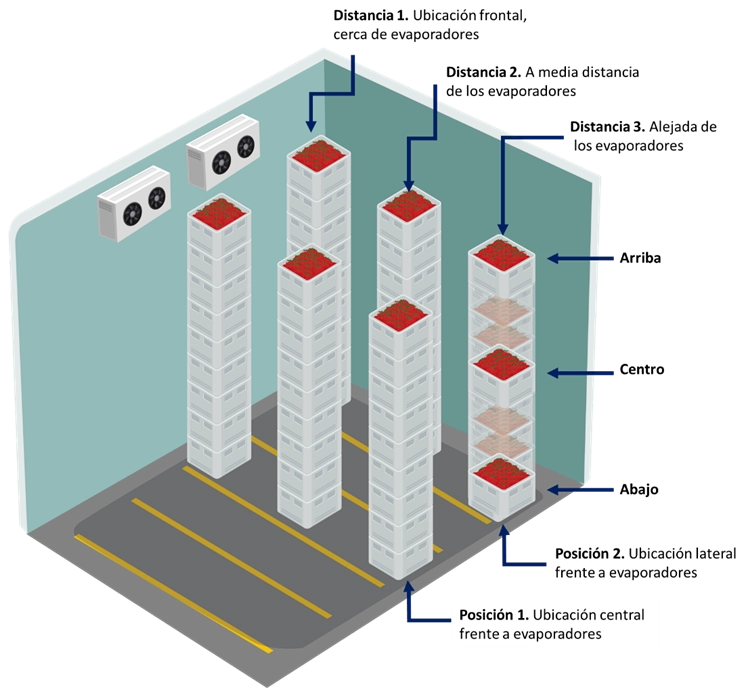

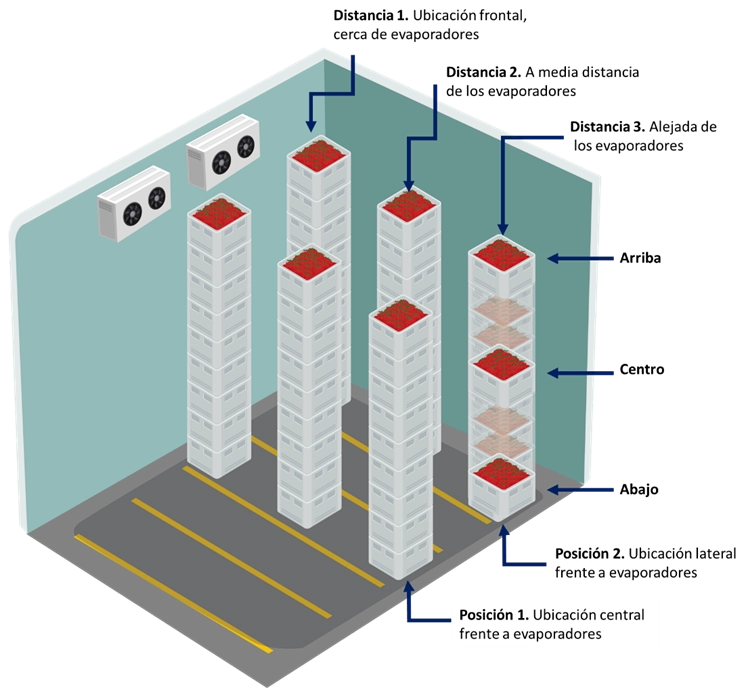

Samples were strategically distributed at different heights (top, middle, bottom) and in lateral and central positions within the bin stacks, allowing the internal microclimate variability to be captured.

Figure 1. Sample distribution inside the cold room.

Figure 1. Sample distribution inside the cold room.

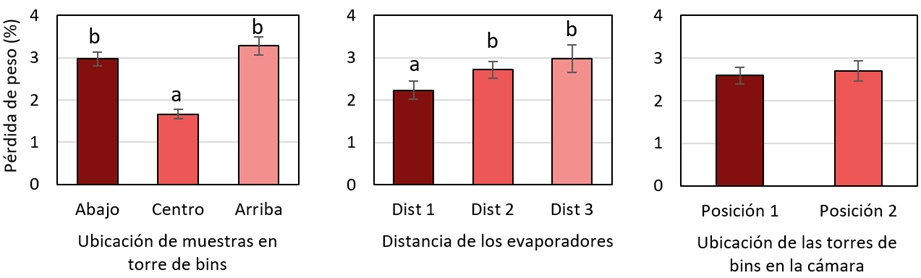

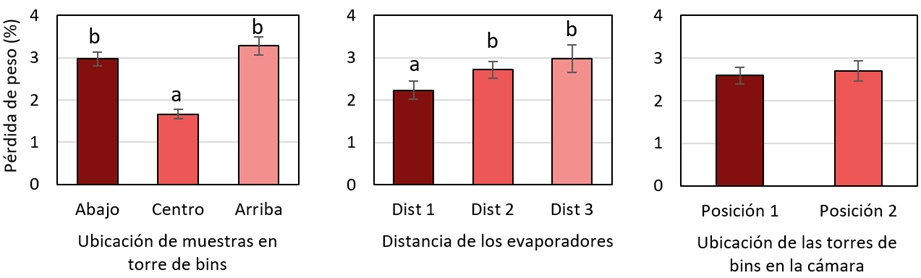

Figure 2 shows how weight loss varies significantly depending on fruit position. Upper bins, more exposed to dry air flow, exhibit the highest losses, with values close to 5% by day eight, while lower positions, benefiting from better cold air incidence, show markedly lower losses.

This trend confirms the presence of critical zones characterized by high VPD, reinforcing the need to consider the physical distribution of fruit when evaluating its physiological behavior inside cold storage rooms.

Figure 2. Weight loss as a function of position within the cold room. Upper and exposed zones show the greatest impact of VPD.

Results: effect of VPD and humidification

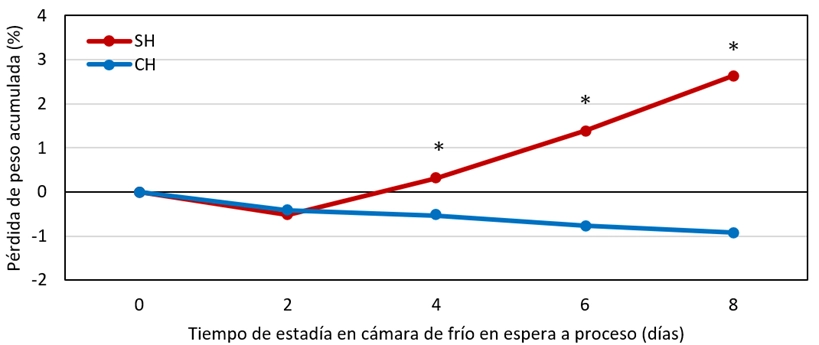

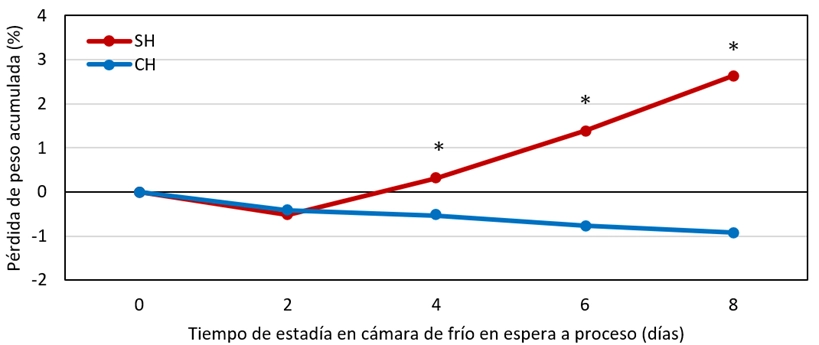

During the first three days, residual moisture from the hydrocooler acted as an initial buffer, reducing evaporation. Once this effect dissipated, VPD became the dominant factor:

- In the non-humidified cold room, fruit began to lose weight from day 3 onward.

- By day eight, average dehydration reached 2.6%, with peaks of 4.7% in the most exposed positions.

The vertical and horizontal variability confirms that fruit position is a determining factor in the level of evaporative stress.

From a physiological standpoint, the cold room behaves more like a mosaic of microclimates than a homogeneous environment.

Benefits of high-pressure humidification

By contrast, the humidified cold room showed a markedly different behavior:

- No fruit dehydration was recorded during the eight days of storage.

- The environment remained stable, with a sufficiently low VPD to neutralize the drying effect of cold air.

- Variability between positions disappeared: humidification homogenized the microclimate, eliminating differences between heights and locations.

These results confirm humidification as an effective tool to protect fruit condition during the waiting period before processing.

Figure 3. Direct comparison of fruit weight between cold rooms with and without humidification. The humidification system completely prevents weight loss for eight days.

Figure 3. Direct comparison of fruit weight between cold rooms with and without humidification. The humidification system completely prevents weight loss for eight days.

Sanitary incidence and prevention

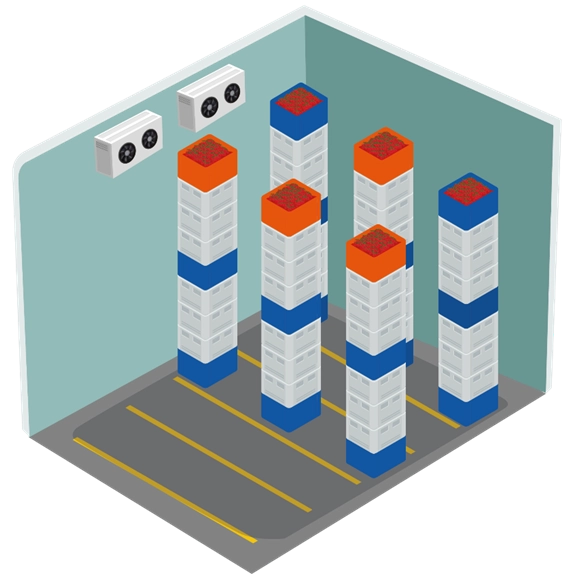

Up to day 6, no cracking or decay was observed in any of the treatments.

By day eight:

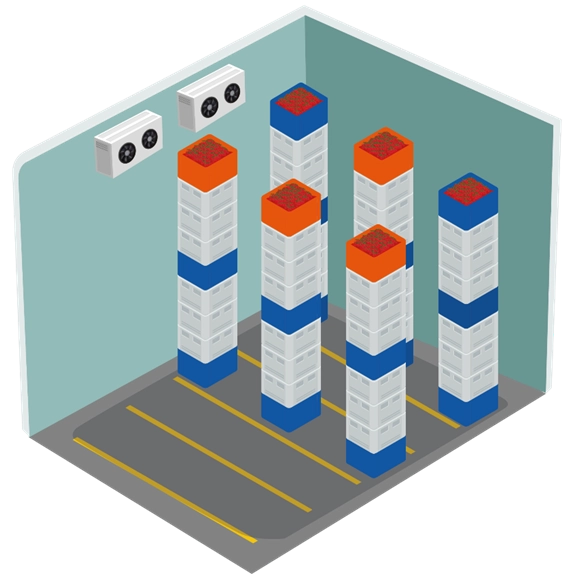

- A slight incidence of cracking (1.37%) and decay (0.05%) was detected exclusively in the upper part of the stack in the humidified cold room.

- By applying a plastic cover on the top bin, incidence dropped to 0%, demonstrating that the damage is triggered by exposure to more intense air flows rather than by humidification itself.

Figure 4. Areas where cracking/decay appeared on day eight. In red, sample positions with damage incidence; in blue, samples without damage. Damage was concentrated exclusively in the upper part of the stacks.

Figure 4. Areas where cracking/decay appeared on day eight. In red, sample positions with damage incidence; in blue, samples without damage. Damage was concentrated exclusively in the upper part of the stacks.

Operational conclusions

VPD inside conventional cold rooms can generate significant weight loss, especially in upper zones.

High-pressure humidification eliminates dehydration for at least eight days of pre-processing waiting time.

Internal heterogeneity of the cold room remains a determining factor.

Simple measures, such as covering the top of the stacks, can prevent sanitary damage associated with excessive air flow.

Humidification technology makes it possible to extend the operational window without compromising product condition, preserving visual and commercial quality.

Cover image source: SL Fruit Service

Internal image sources: linkedin.com

Valentina Vesely

R&D Manager for industrial projects at Johnson

Cherry Times – All rights reserved