A hydroponic cherry grower in Hungary collaborated with Gremon Systems to find solutions to prevent fruit cracking. With the help of dendrometers, which measure stem diameter, the grower gained deeper insights into controlling osmotic pressure to reduce cherry cracking.

Digital greenhouse

The grower uses the Trutina Berry system, a professional solution for greenhouse monitoring suitable for various types of berries. Developed by Gremon Systems, Trutina digitalizes greenhouse management by consolidating crucial agricultural data on a cloud platform.

“The system tracks key parameters such as container weight, irrigation levels, electrical conductivity (EC), temperature, and drainage levels. It also calculates water absorption rates and measures irradiance, water capacity, humidity, and temperature, all aggregated and presented on the online platform,” explains product developer Újszászi András.

Why cherries crack

The grower faced a challenge with cracked cherries, a common problem in cherry production, which the Trutina system was used to address. One of the most common reasons for cherry cracking is rapid growth, where fast ripening outpaces the skin’s expansion, causing cracks.

In this case, however, the growth of the fruit slowed as ripening approached, making this phenomenon less likely. Sudden rain can also cause cracking by increasing the fruit's water content and internal pressure, but the closed greenhouse environment ruled out this cause.

Some varieties are more prone to cracking, but the variety grown in this case is known for its stability. Environmental stresses, such as temperature fluctuations, strong sunlight, or wind, can also contribute. Although these conditions occur in Hungary from March to May, they are not universal.

Irrigation

After ruling out other potential causes such as humidity and temperature variations, the focus shifted to optimizing irrigation practices. Uneven irrigation, especially after periods of drought, can cause cracking due to the rapid influx of water.

Most experts agree that irrigation strategies play a significant role in the formation of cracks in the fruit. “Our hypothesis was that better control of osmotic pressure could help prevent fruit splitting during growth,” explains András.

Osmotic and root pressure

Osmotic pressure occurs within the plant and controls the flow of water across the cell membrane. The level of osmotic pressure depends on the concentration of solutes (such as salts and sugars) inside the cells.

If the concentration inside the cell is higher than outside, water flows into the cell via osmosis to reach equilibrium. Osmotic pressure is essential for maintaining turgor pressure, allowing plants to retain their structure and support growth.

At the same time, root pressure plays an important role. “Root pressure refers to the hydrostatic pressure in the roots, which aids in the absorption of water and solutes. It results from the transfer of ions across root cell membranes, creating an osmotic gradient. This pressure is crucial for water transfer, especially during periods of low transpiration, contributing to hydration, guttation, and nutrient transport,” adds András.

Use of Dendrometers

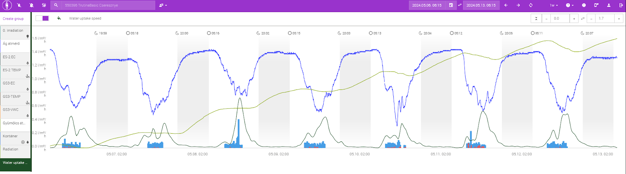

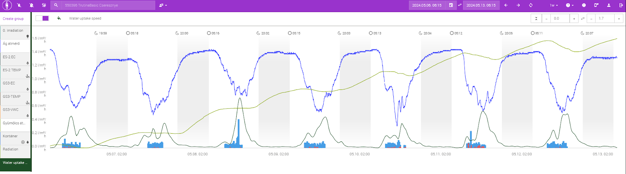

To further reduce cracking, the grower integrated dendrometers into the Trutina system. Two dendrometers with a resolution of 0.002 mm were installed, one on the fruit and the other on the branch. These sensors collect data every 5 seconds, measuring the diameter or circumference of the plant branches.

This allows long-term monitoring of growth, physiology, and osmotic pressure, which are believed to contribute to fruit cracking. The goal was to control osmotic pressure more effectively to prevent cracking during growth.

Managing Osmotic Pressure

The irrigation strategy was adjusted to focus on managing osmotic pressure from flowering to harvest, ensuring proper drainage and maintaining appropriate ΔEC and pH levels. Observations indicated that the branches and fruits showed pulsing movements over 24 hours, attributed to changes in osmotic pressure.

By avoiding irrigation during periods of high osmotic pressure and ensuring gradual changes through climate computer adjustments, the grower was able to reduce the risk of increased root and osmotic pressure.

To read the full report, click here

Read the full article: Hortidaily

Images: Hortidaily

Cherry Times - All rights reserved