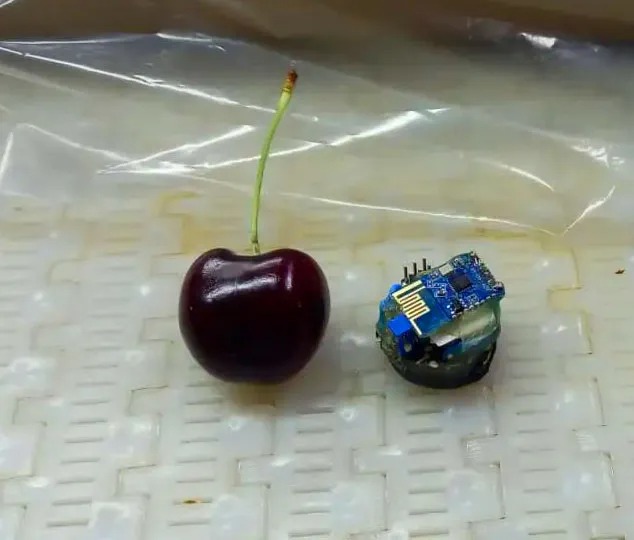

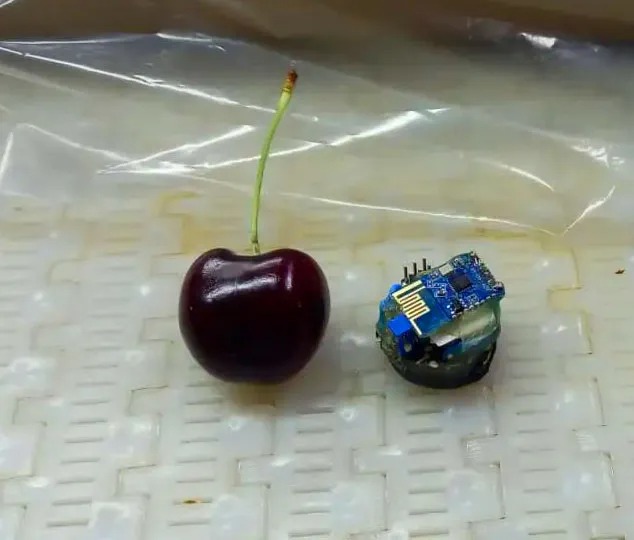

So far, in 2024, Argentina has exported 7,210 tons of cherries to Europe, the United States, Hong Kong, Singapore, and China, with an average price of 4 dollars per kilo, according to the Argentine Chamber of Integrated Cherry Producers (CAPCI). To maintain this commercial value and improve the quality of the cherries destined for export, a team of INTA specialists developed an electronic cherry that records the points where the fruit is hit and allows processes to be improved.

“To reduce as much as possible the damage sustained by the cherry during the packaging and final transport stages, we developed an electronic cherry with sensors that go through the processes alongside the rest of the fruit and report the movements and impacts the fruit receives,” explained Andrés Moltoni, head of the INTA Agroelectronics Laboratory.

According to the expert, during packaging and transport processes, cherries receive hits that later cause surface damage to the fruit - the so-called pitting - which reduce its commercial value.

“On average, 5% of cherries are lost due to pitting,” and he did not hesitate to estimate that ‘the application of this technology allows for process improvement and proper decision-making could lead to a 50% reduction in losses, that is, 2.5% of all exported cherries, amounting to 180,000 kilos, which is equivalent to 720,000 dollars.’

In this regard, Liliana San Martino - a researcher at INTA Los Antiguos, Santa Cruz - took a step further, recognizing that “losses due to pitting in packaging plants can vary between 10 and 40%, according to recent INTA tests.”

According to the specialist, “cherries are a very delicate fruit that requires careful handling and that shows the consequences of mistreatment up to 3 weeks after receiving the impact, that is, at the destination.” Hence the importance of reducing this impact.

A Technology as Small as It Is Innovative

The electronic cherry is a prototype not yet available for packaging centers. It is a second updated version that, according to the INTA electronics engineer, incorporates innovations such as a wireless Bluetooth transmitter, which allows the cherry to connect to a mobile device, and a rechargeable lithium battery with dimensions and weight suitable for the prototype's needs.

At the same time, the new version of the electronic cherry is equipped with an accelerometer with a greater scale background to record impacts. “The encapsulation covering the equipment was also improved, for which a 3D print was carried out, and several materials were tested, from hard plastics to flexible materials with different thicknesses, until finding the combination that achieved the best results in the measurements,” explained Moltoni.

Source: Norte

Image: Norte

Cherry Times - All Rights Reserved