The 2024 season promises a 59% increase in cherry production in Chile, representing both opportunities and challenges for the sector. Pitting, one of the major challenges, requires pre- and post-harvest solutions, with packaging playing a crucial role.

This will be a high-production season for cherries in Chile, with a 59% increase compared to estimates. Typically, this entails a series of actions both pre- and post-harvest to ensure good quality and condition, given the overproduction per plantation.

Among the issues arising from the heavy load is the increased likelihood of producing small-sized fruits with lower firmness, making them more prone to softening and mechanical damage, known as pitting. During the pre-harvest stage, pruning and thinning are important.

Thinning, particularly early thinning, is more likely to ensure uniformity of the harvest and the final characteristics of the fruits. There are also late chemical treatments that can be applied after harvest to strengthen the skin.

After harvest, careful handling is essential: transportation must be swift, avoiding sudden movements. Fruits should be handled in trays or dividers that limit contact and pressure, and should be kept refrigerated at low temperatures with high relative humidity throughout the process. Additionally, proper handling on the processing line is important to avoid bruising the fruits.

Although cherry varieties like Bing, Regina, Santina, and Lapins are resistant to pitting, all can be susceptible to some extent. It's worth noting that cherries have a viscoelastic tissue, meaning they exhibit both elasticity and plasticity. They can contract and return to their original state or yield and not fully recover. Thus, understanding the relationship between resistance and deformation is crucial.

For example, the Sweetheart variety has good resistance but low deformability, making it sensitive to pitting. The same applies to Lapins, which is widely produced in Chile. It has high resistance and low deformability but is still susceptible. This has led to studies with exporters to better understand the role of packaging in preserving cherry quality.

Packaging as an Ally in Preservation

PacLife works with plastic polymers like low-density polyethylene (LDPE) and biaxially oriented polypropylene (BOPP), offering medium-to-low water vapor permeability, reducing weight loss and maintaining fruit firmness.

Studies conducted each season show that thanks to these polymers, dehydration of less than 1% has been observed in various export species. For blueberries, the loss was 0.0-0.1% in the 23-24 season after 90 days, and for cherries, it ranged between 0.3% and 0.5% after 45 days. These results reveal a direct correlation between dehydration and the generation of pitting, indicating that secure packaging significantly helps maintain fruit condition.

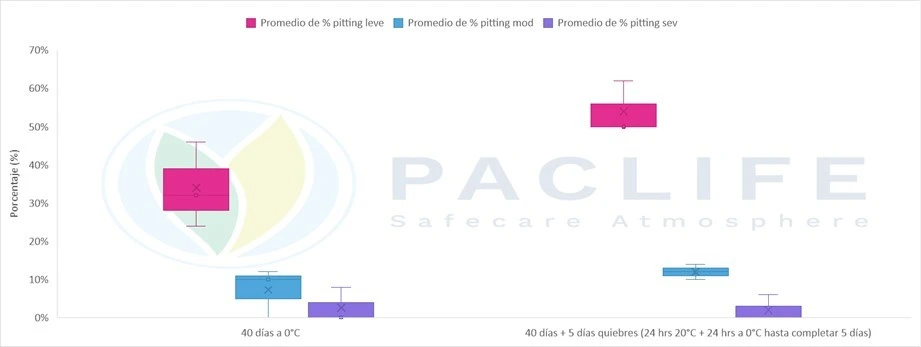

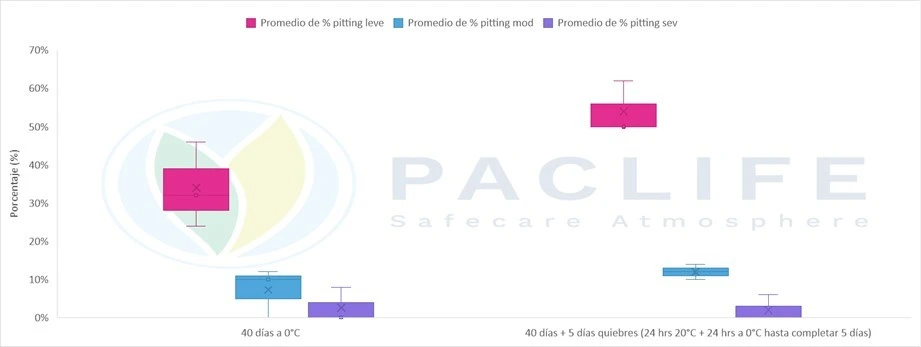

The following graph shows the results of a 23-24 season study on Lapins cherries.

Graph 1: Percentage of pitting defects in treatment 0 polymer (polyolefin, nylon, or polyamide) in flowpack format 2.5 kg var. Lapins size 2JD. 40 days at 0°C cold and 40 days at 0°C plus 5 days of thermal pause.

Graph 1: Percentage of pitting defects in treatment 0 polymer (polyolefin, nylon, or polyamide) in flowpack format 2.5 kg var. Lapins size 2JD. 40 days at 0°C cold and 40 days at 0°C plus 5 days of thermal pause.

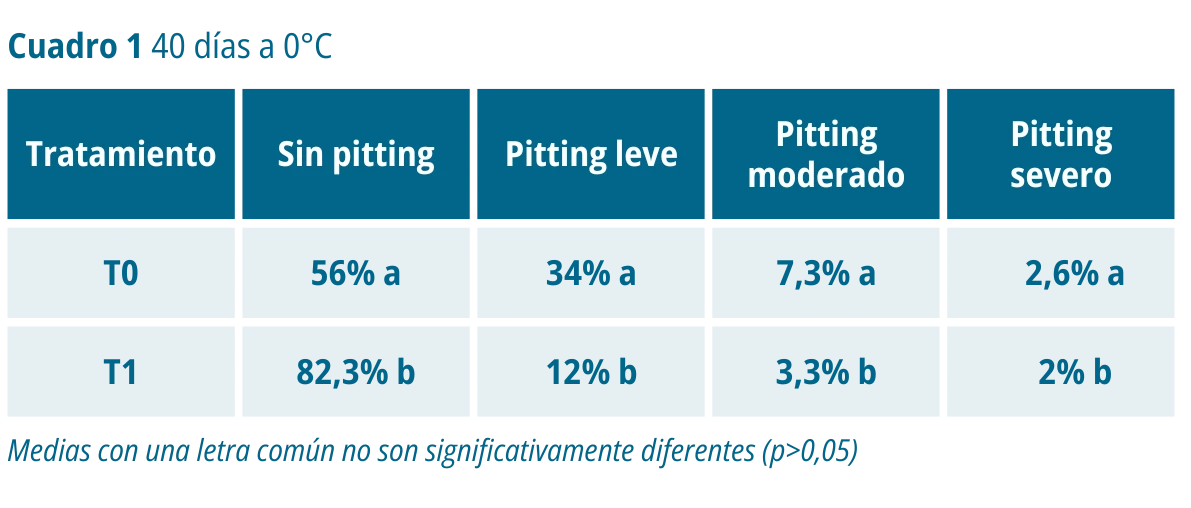

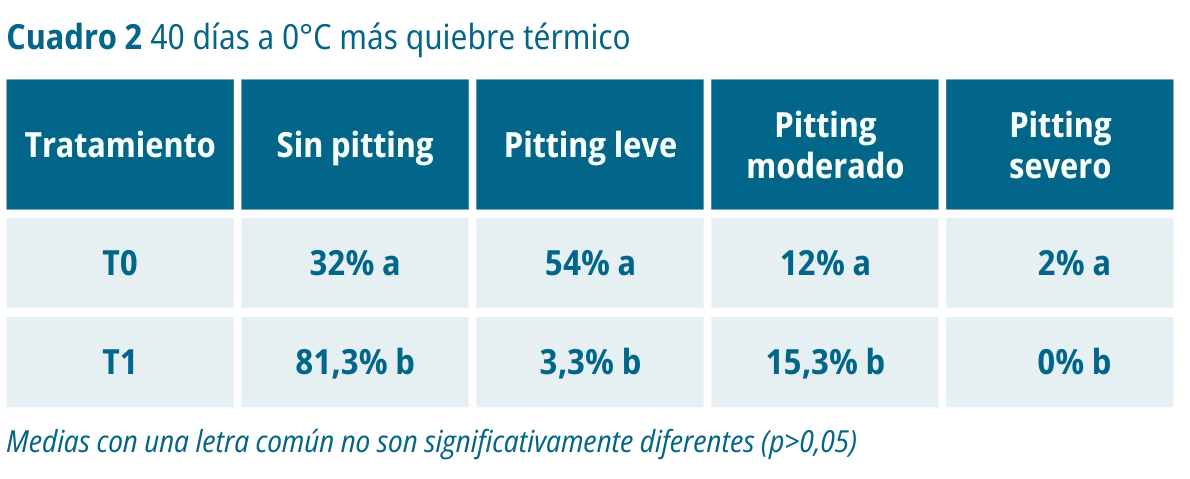

The graph shows a clear difference between polymers: on the left, packaging made with polyamides, nylon, or blends such as polyolefins exhibits 3-90% higher water permeability compared to LDPE or BOPP, which extract more water vapor from the fruit into the environment, resulting in greater weight loss and higher susceptibility to pitting. Comparison of averages using Fisher's LSD test (Alpha = 0.05).

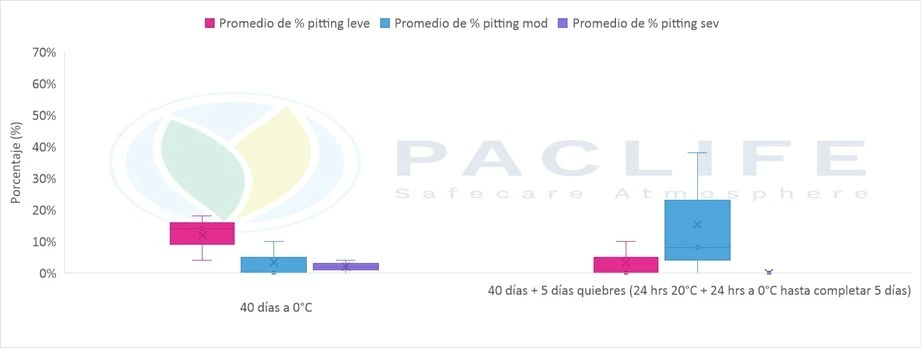

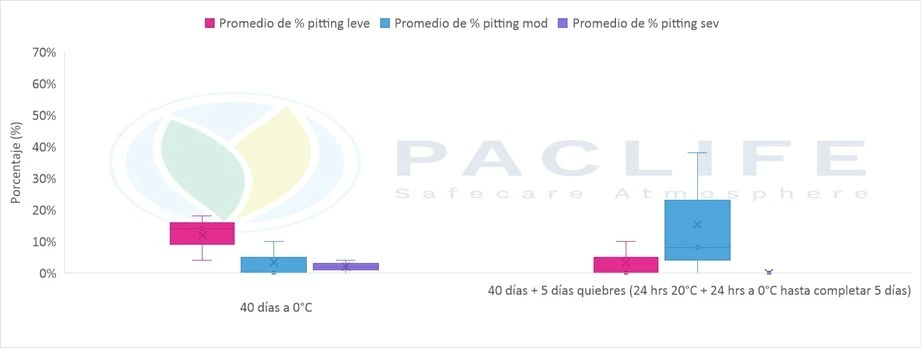

Graph 2: Pitting percentage with PacLife BOPP treatment 1 (biaxially oriented polypropylene) polymer in flowpack format 2.5 kg var. Lapins size 2JD. 40 days at 0°C cold and 40 days at 0°C plus 5 days of thermal pause.

Graph 2: Pitting percentage with PacLife BOPP treatment 1 (biaxially oriented polypropylene) polymer in flowpack format 2.5 kg var. Lapins size 2JD. 40 days at 0°C cold and 40 days at 0°C plus 5 days of thermal pause.

Raw materials such as polyethylene or polypropylene have lower water vapor permeability, helping maintain the internal moisture of the product and, in the case of PacLife, preventing dehydration beyond 1%.

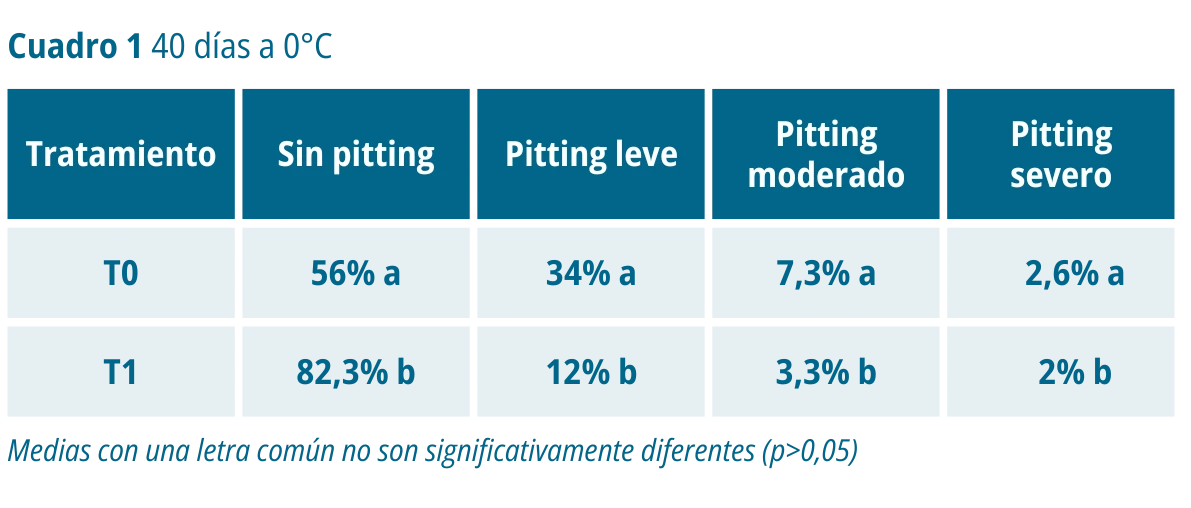

Table 1: Statistical analysis according to Fisher's LSD for Graph 1.

Table 1: Statistical analysis according to Fisher's LSD for Graph 1.

We know that pitting is a major challenge for the cherry industry, which aims to reach the Chinese market with the best possible quality and condition. Therefore, implementing appropriate strategies at each stage is critical to reducing risk and achieving fruit in good condition, protecting its commercial value.

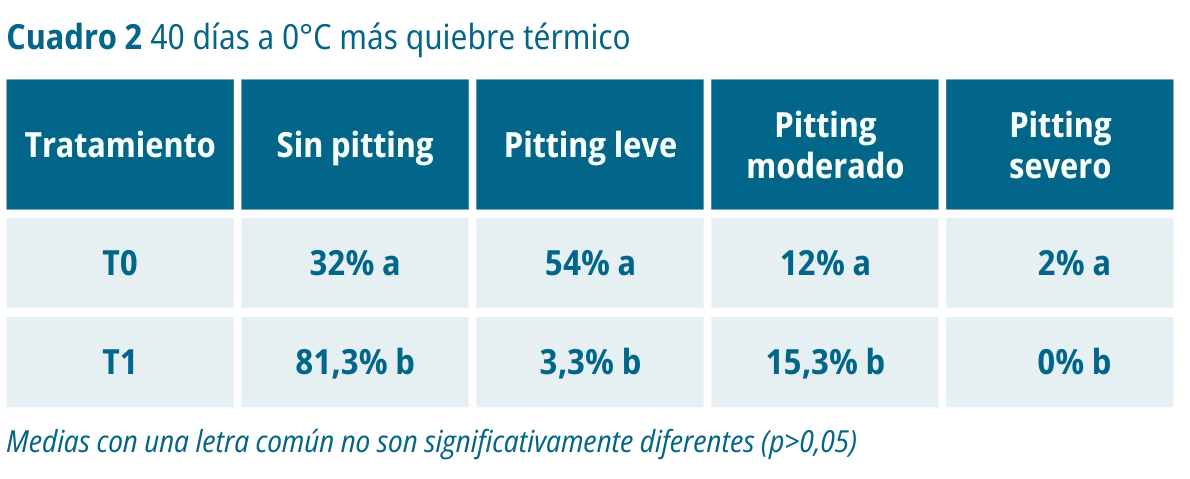

Table 2: Statistical analysis according to Fisher's LSD for Graph 2.

Table 2: Statistical analysis according to Fisher's LSD for Graph 2.

Another important aspect is sustainability: several industry operators are moving towards more sustainable practices, and our packaging, made with recyclable virgin raw materials, offers a responsible and advantageous option for the cherry export industry.

Source: PACLIFE

Images: PACLIFE

Marcela Paz Silva Acevedo

Agricultural Engineer - Postharvest PacLife

Cherry Times - All rights reserved