ESPAGRY IBÉRICA is a family business from Extremadura, founded in 1993 by an Italian-Argentine couple, Karina Bernasconi Díaz and Ricardo Mantaut. Today, the company’s board of directors includes the second generation. Located in Malpartida de Cáceres, in the northern part of the region, it currently has 17 permanent employees, increasing to about 50 during the cherry season.

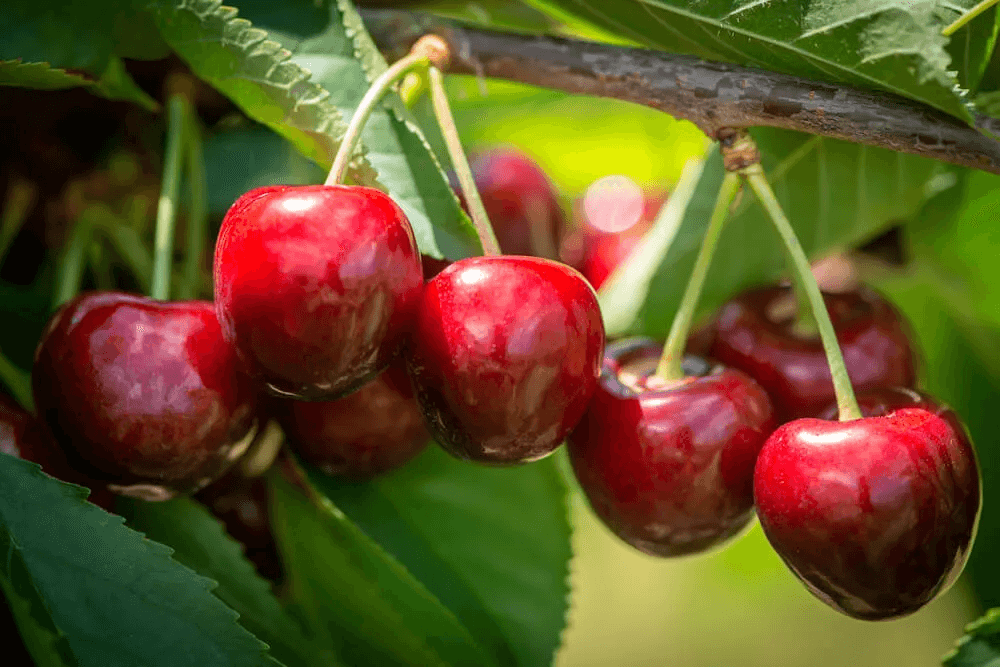

The main activity of this SME focuses on the supply of the fruit industry, especially cherries. “Among other things, we supply cherries for Mon Cheri chocolates by Ferrero and also cherries for cocktails, cakes, etc. We do not produce a finished product, except for the natural cosmetics brand Be Cherry Cosmetics,” explains Ainoha Mantaut, production engineer. Moreover, over 80% of the fruit is destined for export.

The Need for Digitalization and Automation

The managers of ESPAGRY IBÉRICA needed to digitalize part of the production process and opted for the purchase and installation of a machine with artificial intelligence to automatically select cherries. The cost of the machine was partially subsidized by the regional government.

However, to benefit from this aid, the company needed a technical report from an authorized company, so they turned to BERS Consulteam, a regional consulting firm specializing in managing subsidies for improving the competitiveness of SMEs in Extremadura.

Ainoha Mantaut explains: “They were the ones who told us about the Activa Industry 4.0 subsidy and that it wouldn’t cost us anything. They told us we didn’t need to pay anything upfront and that it was easy, so we applied.” In the end, “we needed a report from a technician for the machine subsidy, and they also provided additional consultancy in other areas of the company,” she concluded.

The report not only provided solutions to the specific needs of cherry selection in terms of digitalization and automation but also gave advice on other aspects. “In the report, they explained how to improve customer service or production, for example, along with a series of solutions. Aspects that we hadn’t considered before, all tailored to our business.”

“We are in a historical moment where there is constant talk about SMEs and digitalization, as if there were a single model for SMEs and one way to approach digitalization. The first and most important thing is to understand that digitalization is not something ethereal or a magic formula that applies to any company; it must be adapted to each need,” stated José Bayón, General Director of the School of Industrial Organization (EOI).

“Digitalization is an individual, exclusive, and tailored process for each company. Activa Industry 4.0 responds very well to this reality as it funds personalized consultancy for the company. It starts with an analysis of the initial situation and proposes a detailed roadmap for that specific SME, considering variables such as location, sector, level of technological maturity, etc.

"There’s no magic formula, but plenty of know-how and strategic actions aimed at improving competitiveness. Always with a clear guiding principle: if it doesn’t impact the company's competitiveness, digitalization doesn’t make sense,” concludes Bayón.

Easy and Simple Management of Activa Industry 4.0

Mantaut emphasized how easy it was to request support from Activa Industry 4.0 with BERS Consulteam. “They handled everything. We only had to open a profile on the platform and upload the documentation. Afterwards, the consultant developed the report and managed the progress of the work and the visits they made to justify everything. We validated everything comfortably online,” said Mantaut.

Among the main advantages ESPAGRY IBÉRICA achieved with this program are:

- Cost savings: as the technical report was a prerequisite for obtaining the machinery subsidy and represented an additional cost.

- Time savings: managing the subsidies was simple and quick. The company only needed to upload the documentation and validate online the actions loaded by the manager.

- Improved competitiveness: digitalization in the industry is essential to avoid falling behind. It becomes a “must,” explained Mantaut.

- High return on investment thanks to the machine’s working capacity and the overall increase in productivity.

- Generation of more qualified jobs with professionals who know how to operate these machines.

“I encourage all SMEs to apply for the Activa Industry 4.0 subsidy from EOI. There are many advantages because it doesn’t require much time, and you save a significant cost for consultancy. It’s interesting whether you need something specific, like we did, or at a general level. In all cases, it greatly simplifies the process and opens the mind to interesting options for industrializing and digitalizing the company. We highly recommend it,” concluded Ainoha Mantaut.

Source: Muy Pymes

Images: Muy Pymes; NZG

Cherry Times - All Rights Reserved